Double-drive cable disc winding system

A cable and double-drive technology, which is applied in the field of coiling or placing filamentous materials, and winding, can solve the problems of looseness between the wires and the inability to take into account whether the torque motor is stopped, and achieve the effect of enhancing the quality of the wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

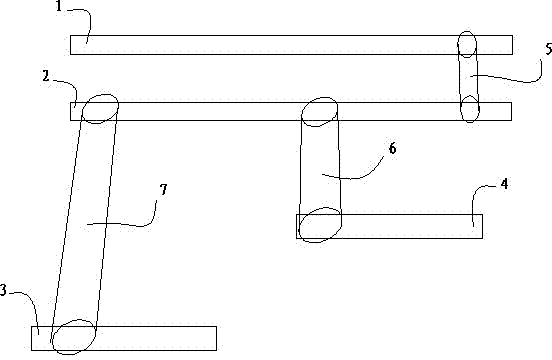

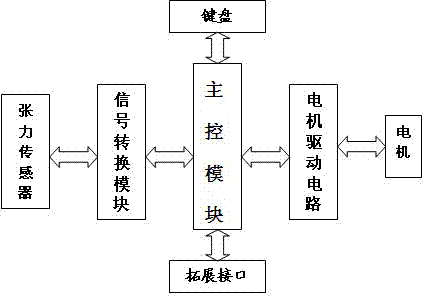

[0018] refer to figure 1 , figure 2 , a double-drive cable closing system, including a double-drive take-up mechanism and a tension control unit; the double-drive take-up mechanism includes a wire-discharging device polished rod 1, an auxiliary shaft 2, a first main shaft 3, and a second main shaft 4; the auxiliary shaft 3 and the The smooth rod 1 of the cable arrangement is connected by chain transmission, and is connected with the first main shaft 3 and the second main shaft 4 by flywheel transmission; the tension control unit includes a tension sensor, a signal conversion module, a motor drive module, a main control module, and a motor; the tension sensor passes through the signal conversion module It is connected with the main control module, collects the cable tension signal and transmits it to the main control module; the main control module is connected with the motor through the motor drive module, and is used to control the rotation of the motor after receiving and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com