Pneumatic wire pushing take-up device

A wire take-up device, pneumatic technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of complex mechanical claw structure, long running time, waste of energy, etc., to reduce the difficulty of electrical procedures, wire diameter span The effect of large distance and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

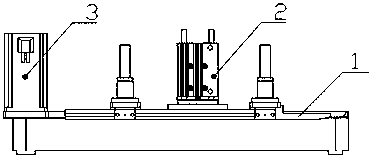

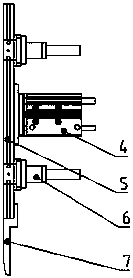

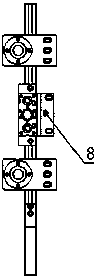

[0023] Such as Figure 1-7 As shown, the present invention provides a pneumatic wire push and take-up device, comprising a bracket 1, a take-up assembly 2 and a conveying assembly 3, the conveying assembly 3 is connected to the take-up assembly 2 through the support 1; the take-up The assembly 2 includes a cylinder 4 , a wire pushing plate 5 , a guide mechanism 6 , a guide plate 7 and a fixing seat 8 , and the cylinder 4 and the guide mechanism 6 are fixedly connected to the bracket 1 and the wire pushing plate 5 respectively.

[0024] In one embodiment, the guide mechanism 6 includes a guide rod 61, a linear bearing 62, a linear bearing fixing seat 63, a buffer pad 64, and a guide rod fixing seat 65; connected; and the guide rod 61 is connected with the pusher plate 5 through the guide rod fixing seat 65 . The guide rod 61 does and only moves linearly through the linear bearing 62 .

[0025] In another embodiment, the guide mechanism 6 includes a guide rail 611, a slider 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com