Breathable and waterproof fabric

A breathable waterproof fabric technology, applied in the field of fabrics, can solve the problems of fabric waterproof and poor air permeability, and achieve the effects of high porosity, excellent antibacterial and anti-corrosion properties, and excellent air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

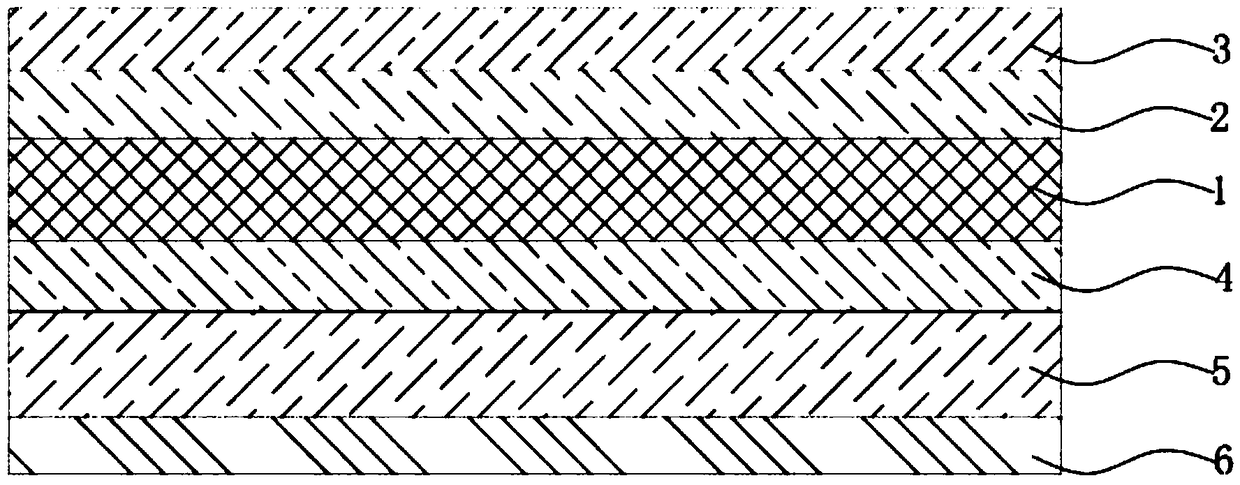

[0018] The breathable and waterproof fabric in this embodiment includes a fabric layer 1, the thickness of the fabric layer 1 is 6mm, and one side of the fabric layer 1 is sequentially provided with a PUR microporous membrane 2 and a PU membrane 3 from the inside to the outside, and the PUR microporous membrane 2 The thickness of the PU film 3 is 0.06mm, and the thickness of the PU film 3 is 0.03mm. The other layer of the fabric layer 1 is provided with a cotton velvet layer 4, a ramie fiber layer 5 and a polytetrafluoroethylene microporous film layer 6 from the inside to the outside. The thickness of the fleece layer 4 is 3 mm, the thickness of the ramie fiber layer 5 is 5 mm, and the thickness of the polytetrafluoroethylene microporous membrane layer 6 is 0.03 mm.

[0019] The preparation method of the above-mentioned air-permeable waterproof fabric comprises the following steps:

[0020] Place the PU membrane 3, the PUR microporous membrane 2, the fabric layer 1, the cotton...

Embodiment 2

[0023] The breathable waterproof fabric of the present embodiment comprises a fabric layer 1, the thickness of the fabric layer 1 is 7mm, and one side of the fabric layer 1 is sequentially provided with a PUR microporous membrane 2 and a PU membrane 3 from the inside to the outside, and the PUR microporous membrane 2 The thickness is 0.08mm, and the thickness of the PU film 3 is 0.05mm. The other layer of the fabric layer 1 is provided with a cotton velvet layer 4, a ramie fiber layer 5 and a polytetrafluoroethylene microporous film layer 6 from the inside to the outside. The thickness of layer 4 is 3mm, the thickness of ramie fiber layer 5 is 6mm, the thickness of polytetrafluoroethylene microporous film layer 6 is 0.05mm, and fabric layer 1 is selected from one layer of cotton cloth layer, chemical fiber layer, leather layer or woolen cloth layer Or a mix of at least two layers.

[0024] The preparation method of the above-mentioned air-permeable waterproof fabric comprises ...

Embodiment 3

[0028] The breathable waterproof fabric of the present embodiment comprises a fabric layer 1, the thickness of the fabric layer 1 is 7mm, and one side of the fabric layer 1 is sequentially provided with a PUR microporous membrane 2 and a PU membrane 3 from the inside to the outside, and the PUR microporous membrane 2 The thickness is 0.1mm, and the thickness of the PU film 3 is 0.08mm. The other layer of the fabric layer 1 is provided with a cotton velvet layer 4, a ramie fiber layer 5 and a polytetrafluoroethylene microporous film layer 6 from the inside to the outside. The thickness of layer 4 is 5mm, the thickness of ramie fiber layer 5 is 7mm, the thickness of polytetrafluoroethylene microporous membrane layer 6 is 0.1mm, and fabric layer 1 is selected from one layer of cotton cloth layer, chemical fiber layer, leather layer or woolen cloth layer Or a mix of at least two layers.

[0029] The preparation method of the above-mentioned air-permeable waterproof fabric comprise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com