Building decorative material machining device capable of pressing and cutting polished tile

A technology for decorative materials and processing devices, which is applied to manufacturing tools, ceramic forming machines, forming conveyors, etc., can solve problems such as affecting the quality of brick blanks and easily sticking to brick blank raw materials, and achieves the effects of convenient use, waste prevention and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

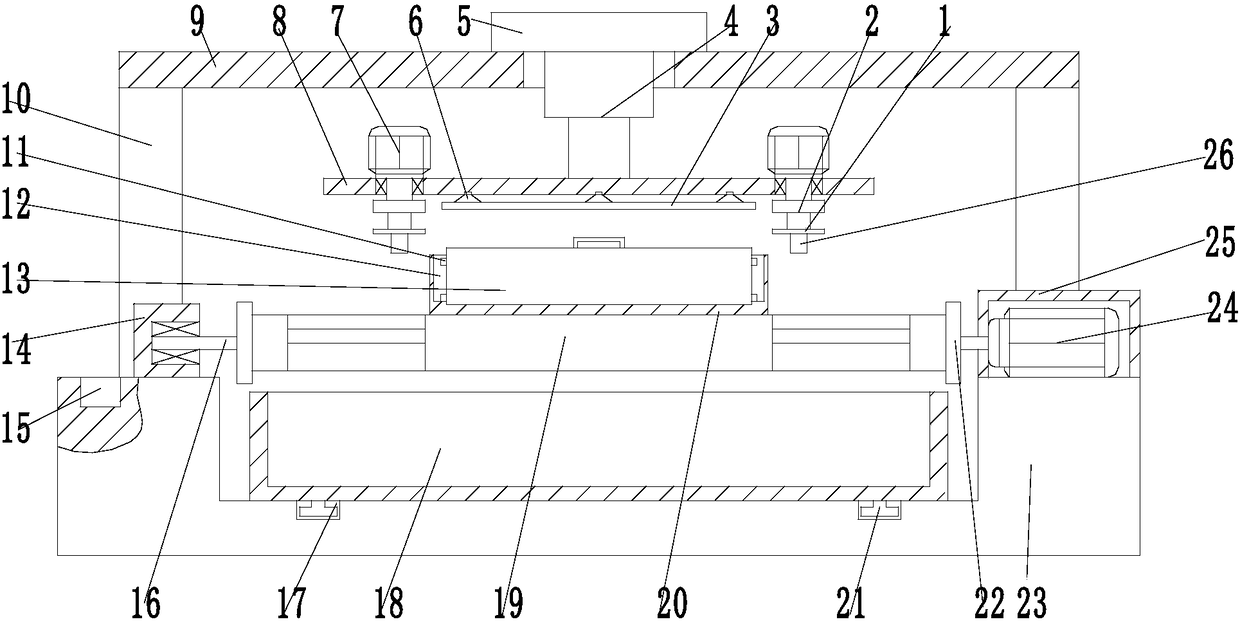

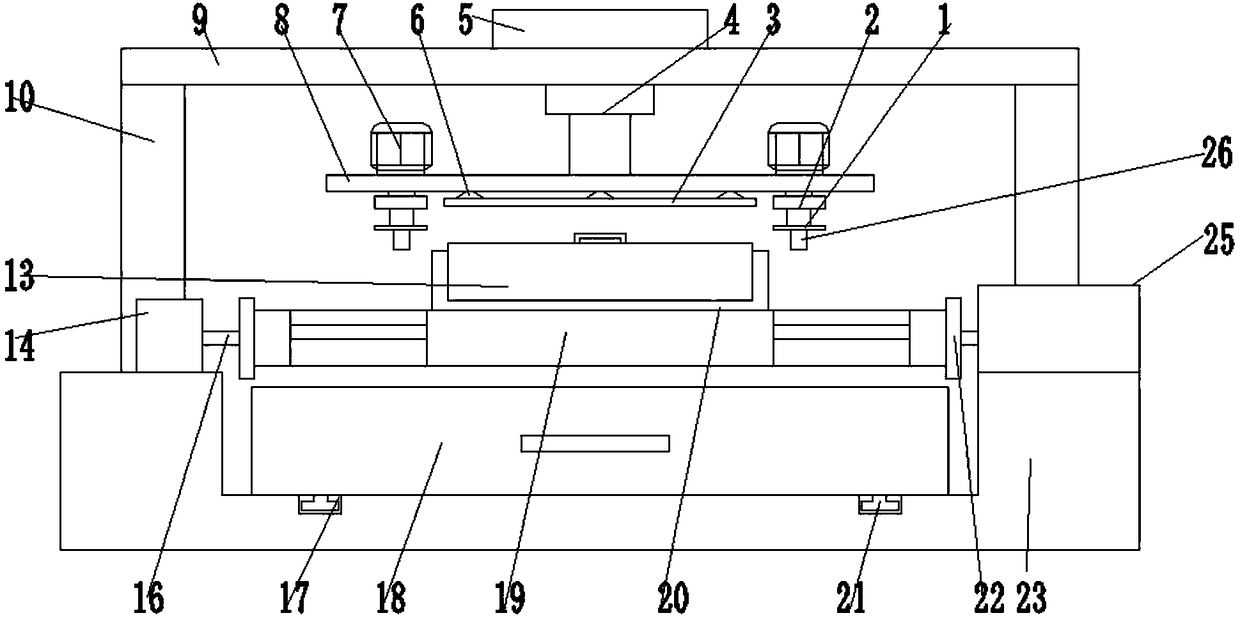

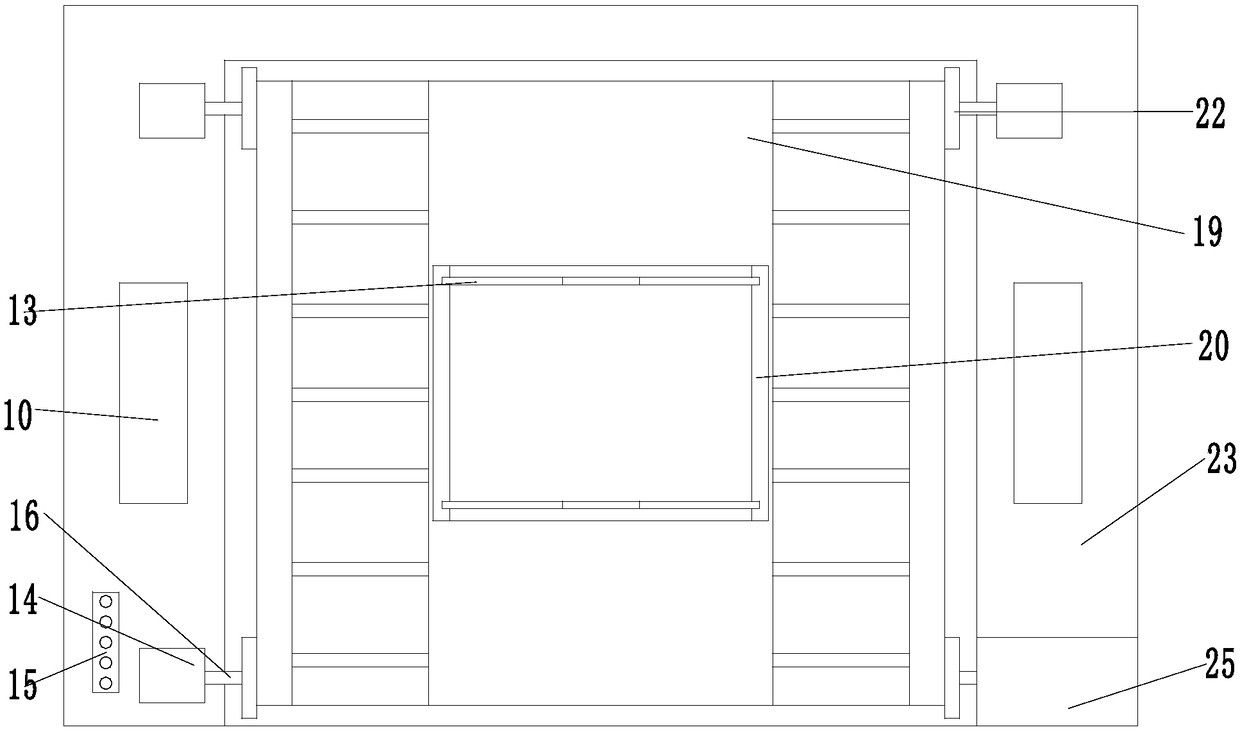

[0019] see Figure 1-3 , a processing device for building decoration and decoration materials capable of pressing and cutting polished tiles, comprising a horizontal plate 9, a conveyor belt 19 and a base 23; The middle part is fixed with a hydraulic cylinder 5 by bolts; the support column 10 is provided with two, and its lower end is fixed on the left and right sides of the upper surface of the base 23 by bolts; It is electrically connected with the control device 15; the control device 15 is inlaid on the left end of the upper surface of the base 23, and a control button is installed on it, so as to control the whole device; the upper end of the hydraulic rod 4 passes through the horizontal plate 9 and is installed on the hydraulic cylinder 5, the lower end is fixed on the middle part of the upper surface of the connecting plate 8 by bolts, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com