Special automatic grinding machine capable of loading and unloading automatically for crankshaft processing and processing method of special automatic grinding machine

A technology of automatic loading and unloading, crankshaft processing, applied in grinding machines, metal processing equipment, automatic grinding control devices, etc., can solve the problem that the grinding degree of the crankshaft is difficult to guarantee, the loading and unloading efficiency and clamping efficiency are low, and the loading and unloading efficiency cannot be obtained. Security and other issues, to achieve the effect of firm and reliable overall structure, high feeding and unloading efficiency, stable and reliable feeding and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

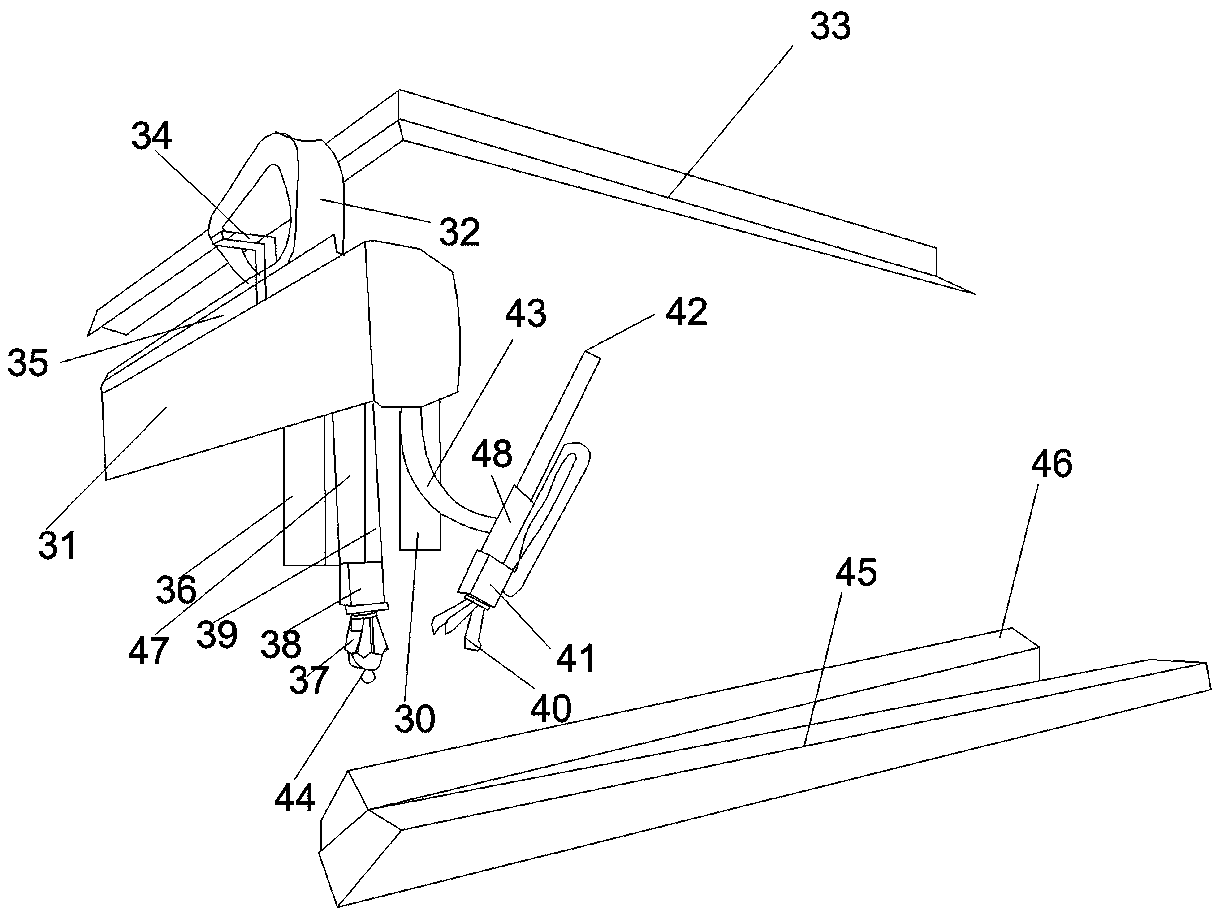

[0035] Such as figure 1 As shown, a special automatic grinding machine for crankshaft processing that can be automatically loaded and unloaded includes a frame 1, a clamping part installed on the frame 1, a grinding part, a distribution box 14 and a loading and unloading mechanism 29. The clamping part includes a first main shaft 3, a first driving motor 4 for driving the first main shaft 3 to rotate, a main shaft tip 10 positioned at the end of the first main shaft 3, a tailstock 9 matching the first main shaft 3 and a tail matching the main shaft tip 10. Seat tip 11, spindle tip 10 and tailstock tip 11 clamp the crankshaft to be machined. The grinding components include a grinding wheel 2, a second main shaft 6 that drives the grinding wheel 2 to rotate, and a second drive motor 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com