Flange plate grinding device

A technology for sharpening knives and racks, used in grinding/polishing safety devices, grinding machines, grinding workpiece supports, etc., can solve problems such as inability to change the angle, inability to perform grinding, etc., to achieve easy processing, reduce processing costs, and environmentally friendly processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

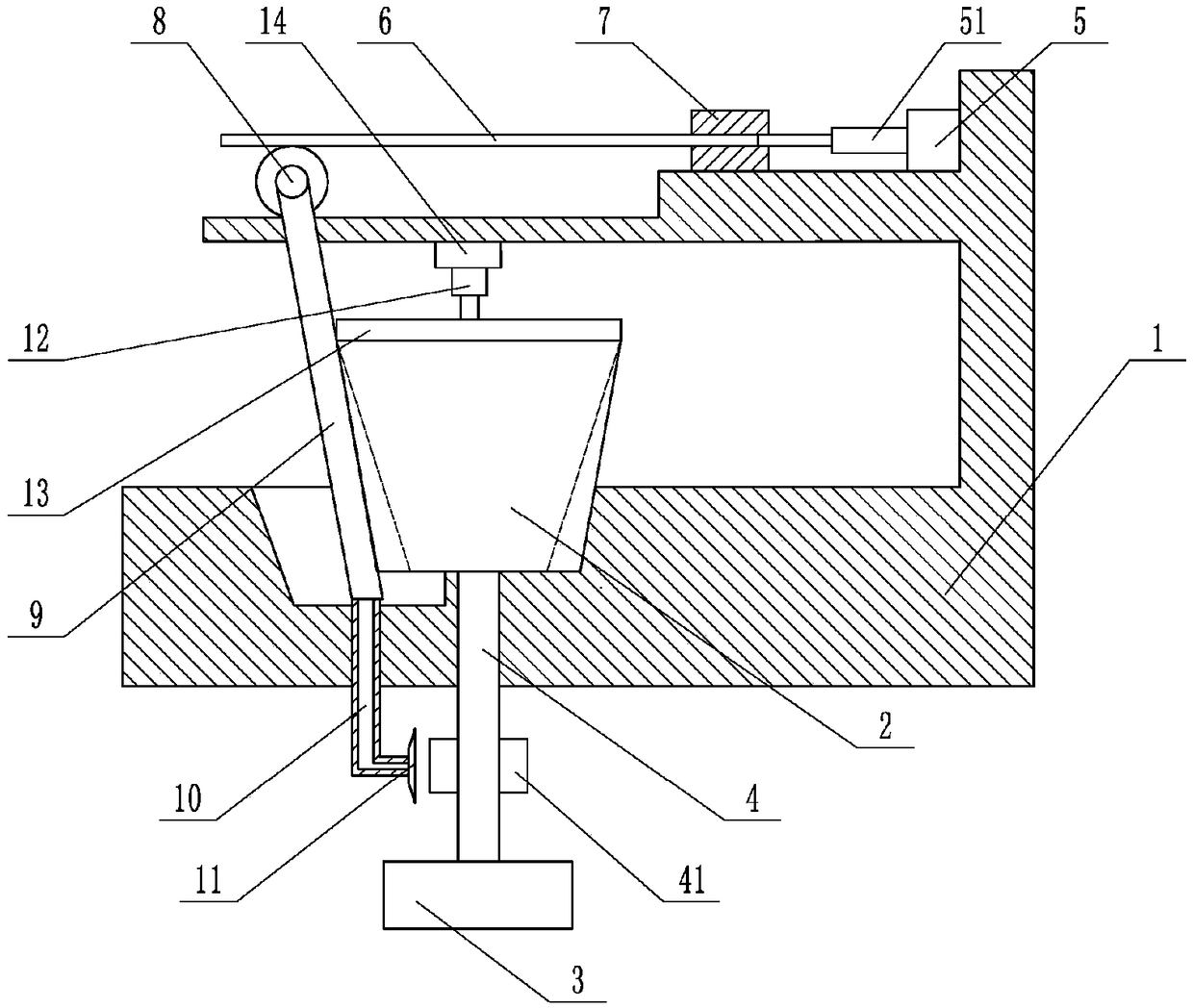

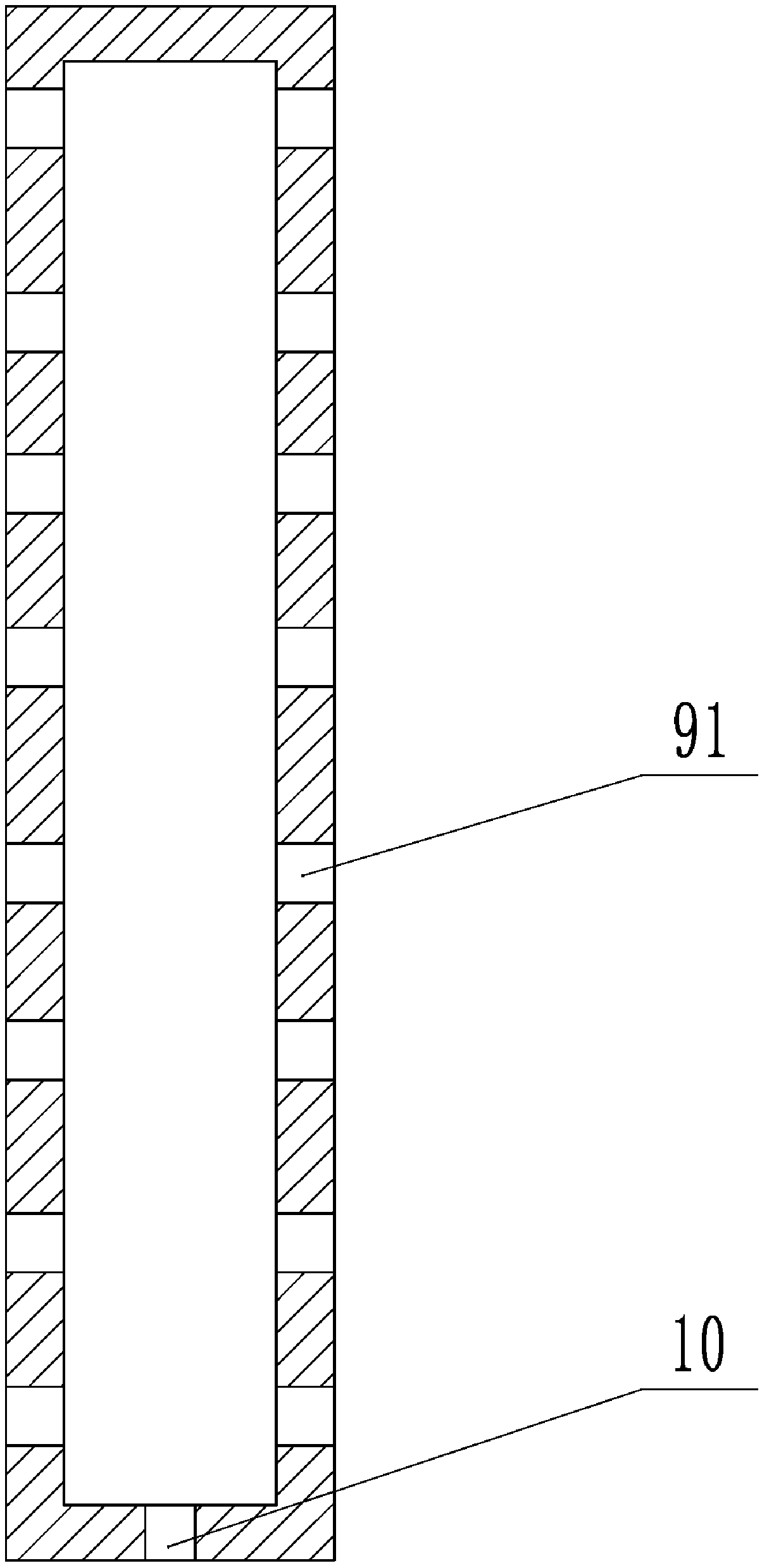

[0020] The reference signs in the drawings of the description include: frame 1, flange plate 2, motor 3, rotating shaft 4, fan blade 41, first cylinder 5, first output rod 51, rack 6, fixed block 7, gear 8 , grinding knife 9, air hole 91, vent pipe 10, air collecting port 11, second cylinder 12, pressing plate 13, rotating block 14.

[0021] like figure 1 As shown, the flange grinding device includes a frame 1 and a grinding knife 9. There is a positioning notch for placing the flange 2 on the frame 1. There is a rotating shaft 4 inside the positioning notch. The rotating shaft 4 runs through the frame 1 and the rotating shaft 4 is connected with a motor 3, when the motor 3 is started, the rotating shaft 4 rotates with the motor 3 and then drives the flange 2 to rotate. The frame 1 is also rotatably connected with a rotating block 14, the second cylinder 12 is welded on the rotating block 14, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com