Automatic assembling jig for power supply, and test device thereof

A technology for assembling jigs and testing devices, applied in power supply testing, assembling machines, electrical components, etc., can solve problems such as low efficiency, high cost, and difficulty in ensuring the consistency of assembled products, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings:

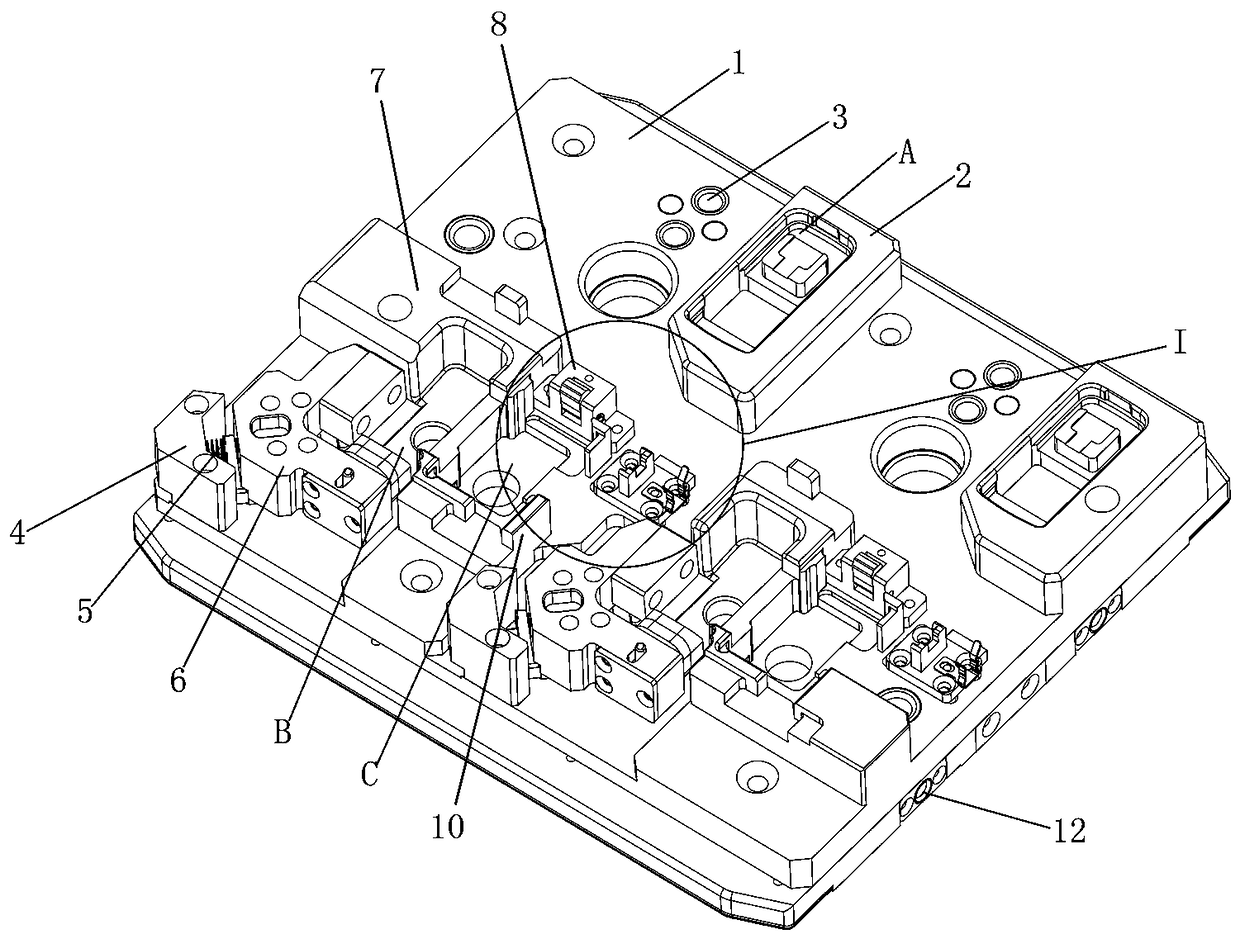

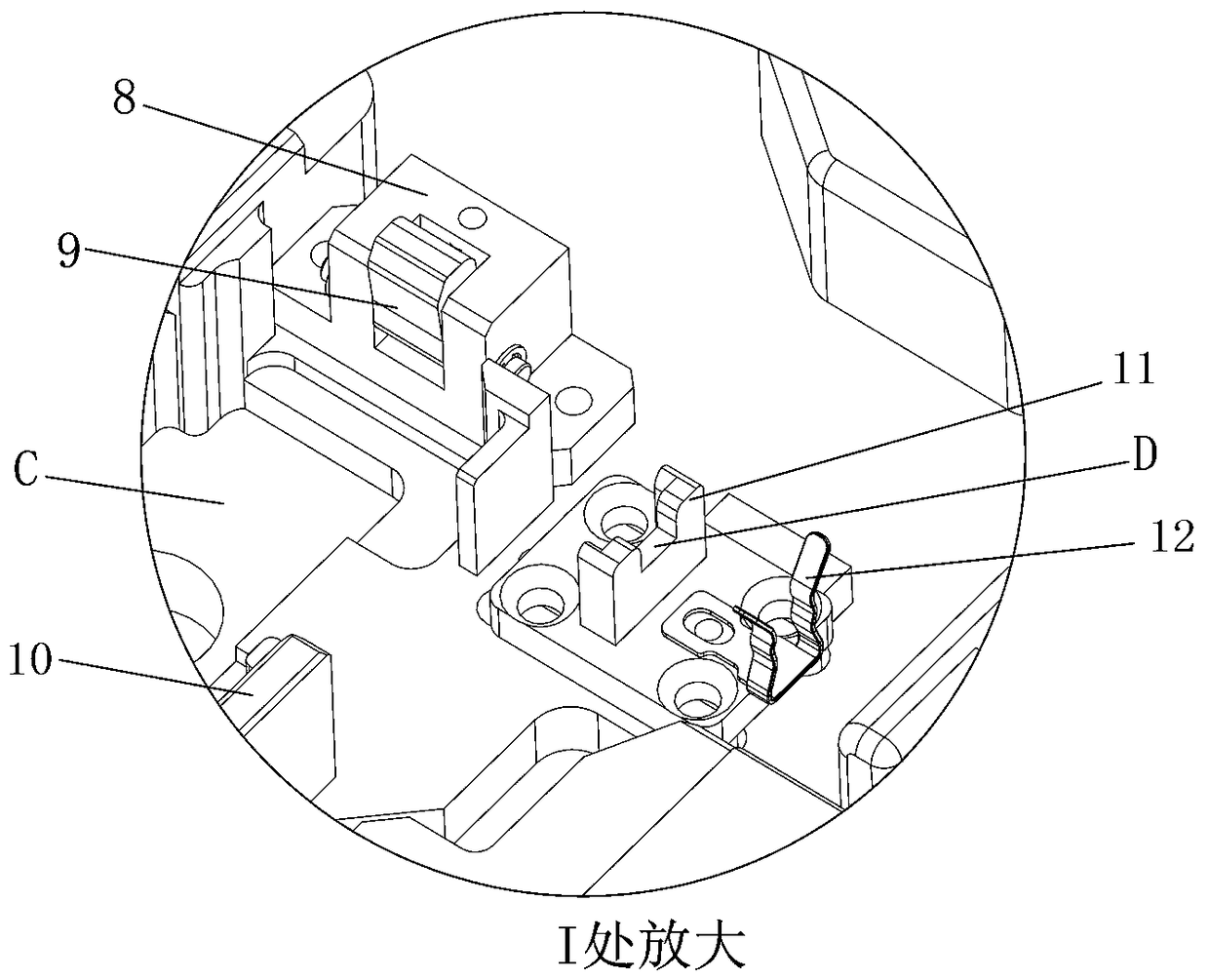

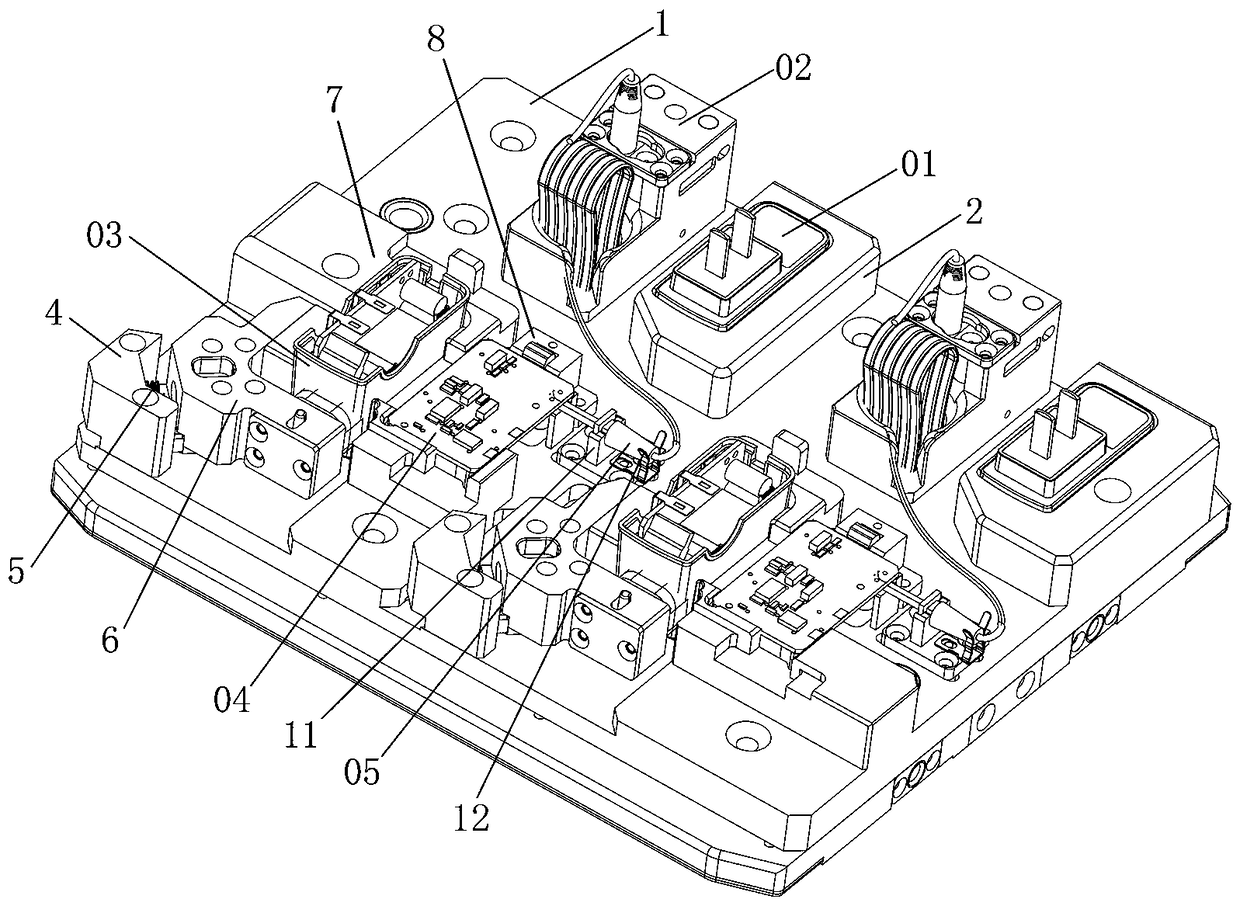

[0038] Such as Figure 1 to Figure 6 As shown, the technical solution adopted by the present invention is as follows: a power supply automation assembly jig, including a jig seat 1, a clamping assembly and a test socket 12, wherein the jig seat 1 is a plate-shaped structure; the clamping assembly At least two sets are included. Each clamping assembly is arranged on the fixture base 1 at intervals along the left and right direction to clamp at least two power supply components; the clamping assembly includes an upper cover base 2, a socket 3, a lower cover clamping part, and a PCB Board clamping components and DC cord clamping components; the upper cover seat 2 is arranged near the rear side of the fixture seat 1, and the upper cover seat 2 is embedded with the upper cover 01; the above-mentioned socket 3 is arranged in the upper cover seat 2 On the left side, the test soc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com