Feature machining method for shell parts

A processing method and shell technology, applied in the CNC machining of complex shells of aviation fuel accessories, feature processing of shell parts, and processing of shell parts, can solve the problems of lack of effective quantitative analysis of processing methods, unfavorable processing experience and Insufficient judgment ability of process parameters and shell parts, etc., to achieve the effect of reducing the time occupied by the machine for programming, improving the quality and efficiency of programming, and improving the quality of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

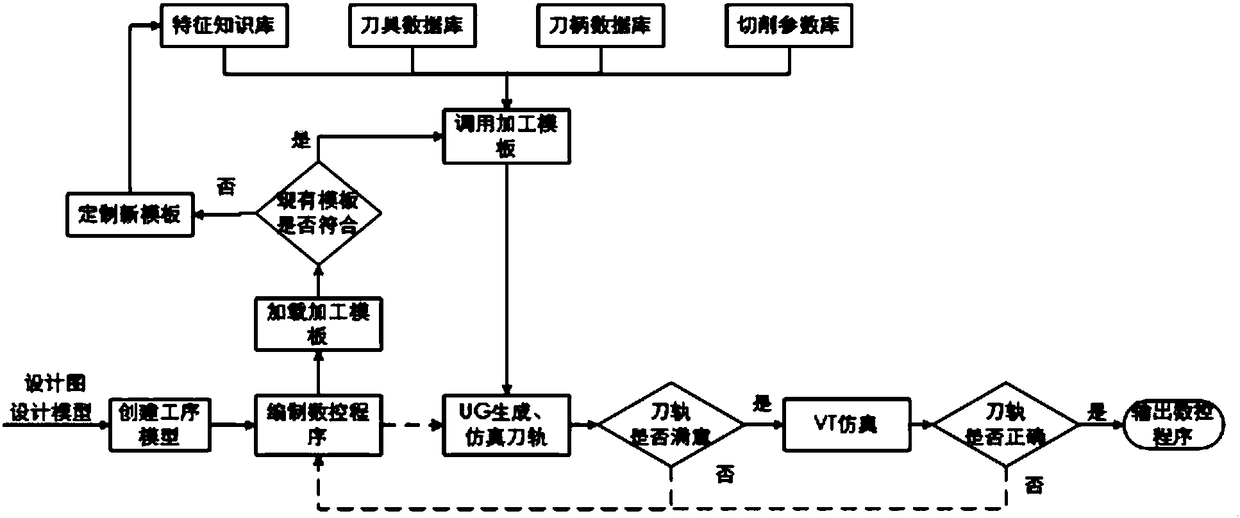

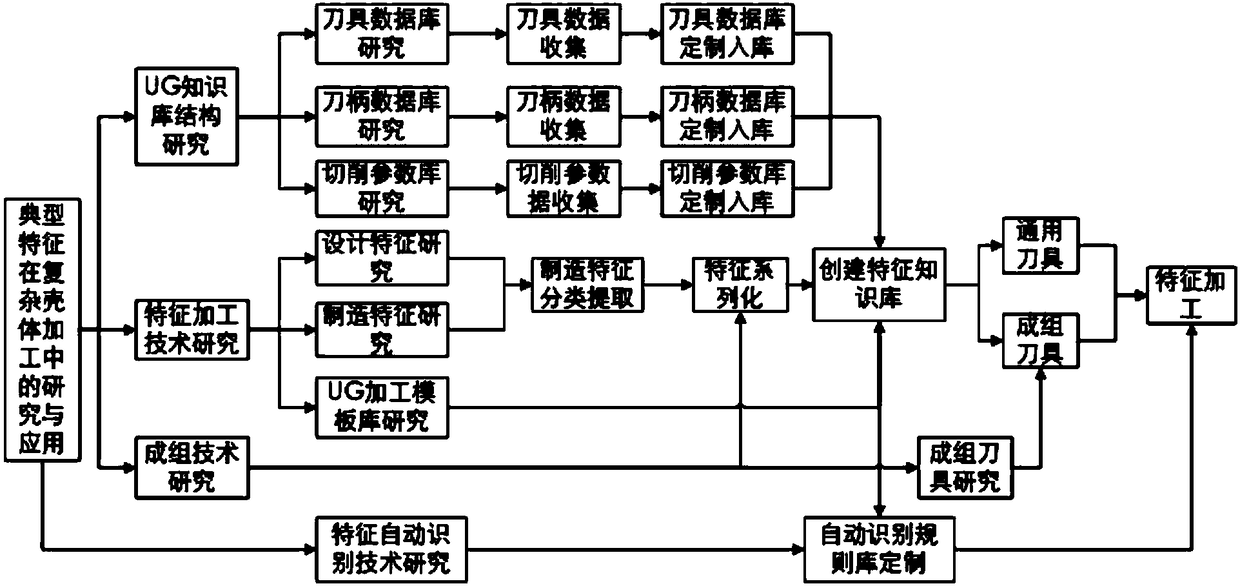

[0039] see figure 1 , figure 2 as well as image 3 , the invention provides a feature processing method for shell parts, the method comprising the following steps:

[0040] 1) Build manufacturing feature knowledge base

[0041] 1.1) Structural feature classification

[0042] In the design stage of complex shells, designers design based on functional requirements and structural attributes, and the formed 3D model of the part is the final shape and functional structure of the product, without considering the needs of downstream manufacturing. In the early stage, the company classified the structural features according to the functional requirements, and formed the product structural features of shell parts through induction.

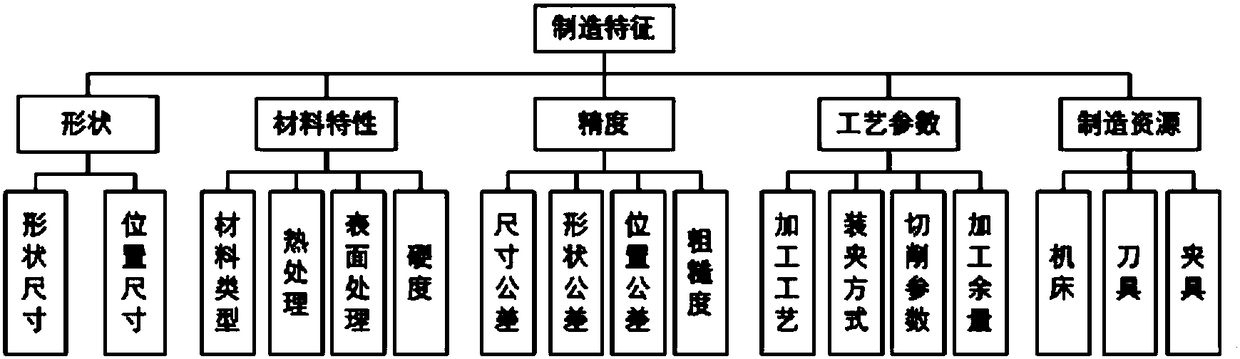

[0043] 1.2) Construct manufacturing feature structure

[0044] In order to transform the above structural features into manufacturing features, combined with the structural features that have been summarized so far, the geometric information and proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com