Industrial screen net with long life

An industrial, long-life technology, used in fixed filter element filters, filter regeneration, dispersed particle filtration, etc., can solve the problems of short service life, waste of cost, inconvenient cleaning, etc., to achieve long service life, simple and convenient cleaning , Easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

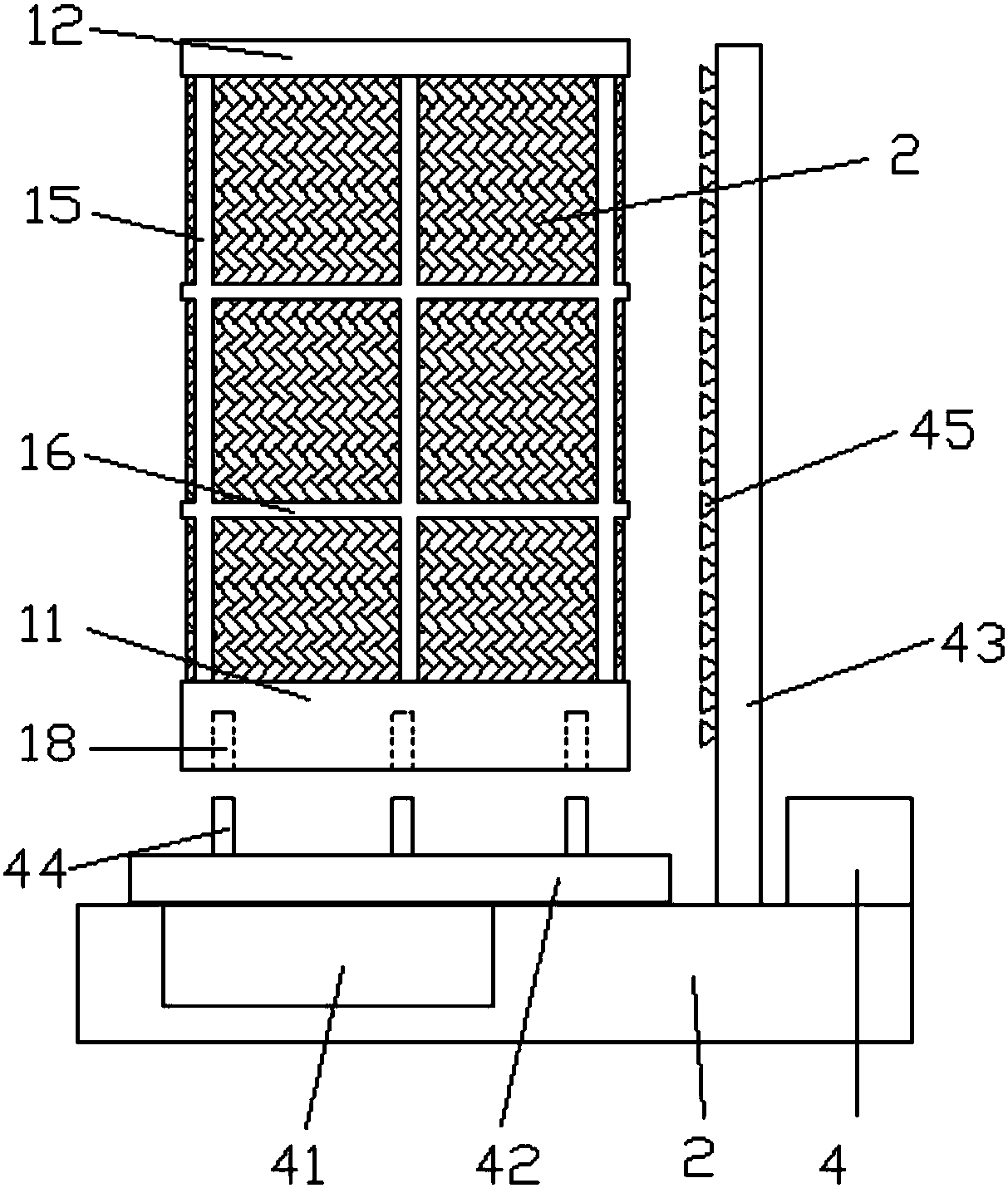

[0021] The purpose of this embodiment is to provide an industrial screen that can automatically clean the mesh, such as Figure 1 to Figure 8 As shown, the filter screen includes a mesh frame 1, a mesh cloth 2, a bottom plate 3 and a cleaning device. The mesh cloth 2 of the present embodiment can be directly cleaned by a cleaning device without disassembly, and can be directly cleaned and put into use again to prolong its use. In addition, it can also be cleaned by disassembling the mesh. Since the mesh body is not welded or stitched with other reinforcing materials, it can be easily cleaned and cleaned.

[0022] Specifically, the mesh cloth 2 is cylindrical, the lower edge of the mesh cloth is provided with a lower snap ring 21 with a V-shaped cross section, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com