Chemotherapy drug mixing device

A mixing device and chemotherapeutic drug technology, applied in the field of medical equipment, can solve the problems of bacterial infection, limited, large bacteria, etc., to achieve the effect of facilitating the flow of liquid medicine, good application prospects, and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

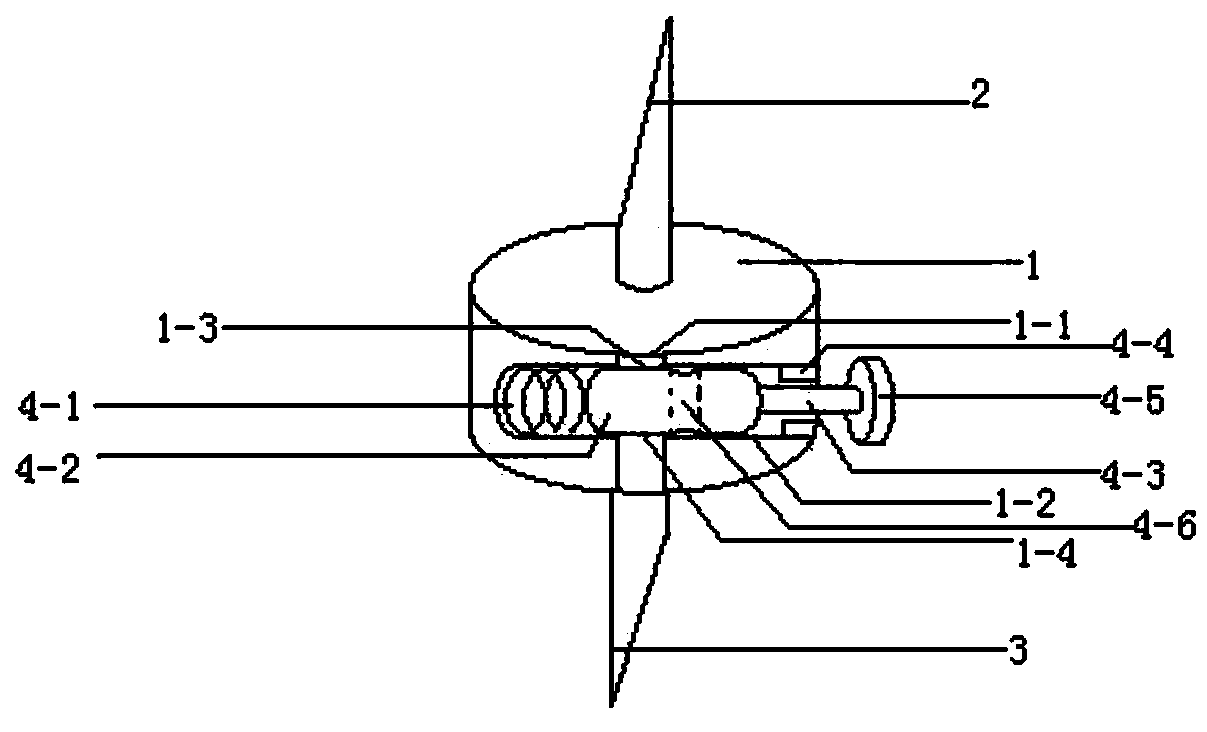

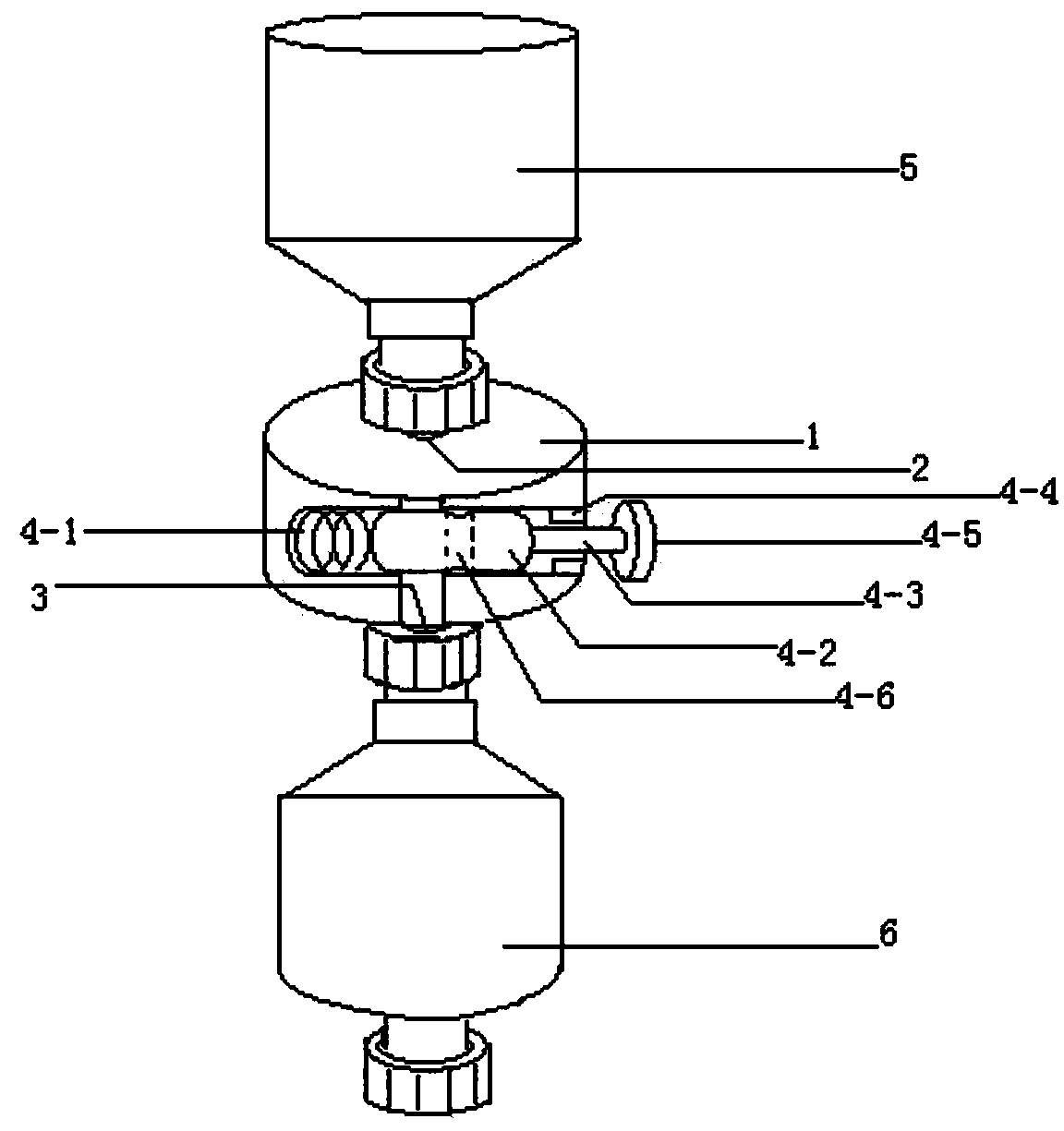

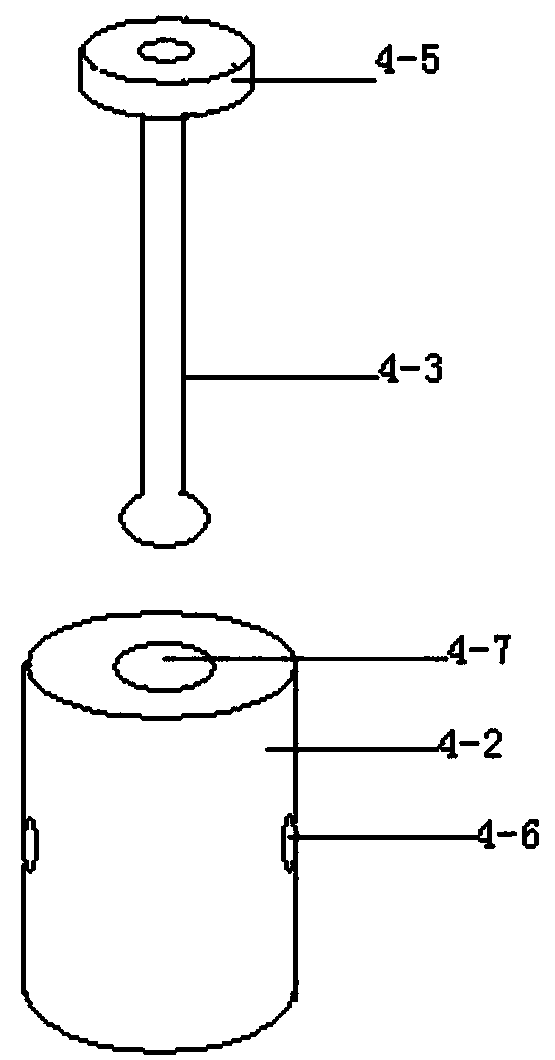

[0017] figure 1 , 2 . As shown in 3, a chemotherapeutic drug mixing device includes an annular connecting seat 1, an upper pin 2, a lower pin 3, and a flow valve 4. There is a through hole 1-1 in the middle of the connecting seat 1 from top to bottom. The pin 2 and the lower pin 3 are respectively installed at the upper and lower ends of the through hole 1-1 in the middle of the annular connection seat, the upper pin 2 and the lower pin 3 have internal openings and the through hole 1-1 in the middle of the connection seat from top to bottom Connected, there is a cylindrical groove 1-2 horizontally in the middle of the connecting seat, the right part of the cylindrical groove 1-2 is an open structure, the inner side of the right end of the cylindrical groove 1-2 has internal threads, and the upper and lower ends of the middle of the cylindrical groove There is an opening 1-3 and 1-4 respectively, the openings 1-3 and 1-4 at the upper and lower ends of the middle of the cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com