Electromagnetic type grain winnowing device

An electromagnetic and grain-based technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of damage to the auditory system of the staff, large vibration of the grain cleaning machine, short service life, etc., and achieve low noise, small vibration, Reduce the effect of damage to the auditory system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

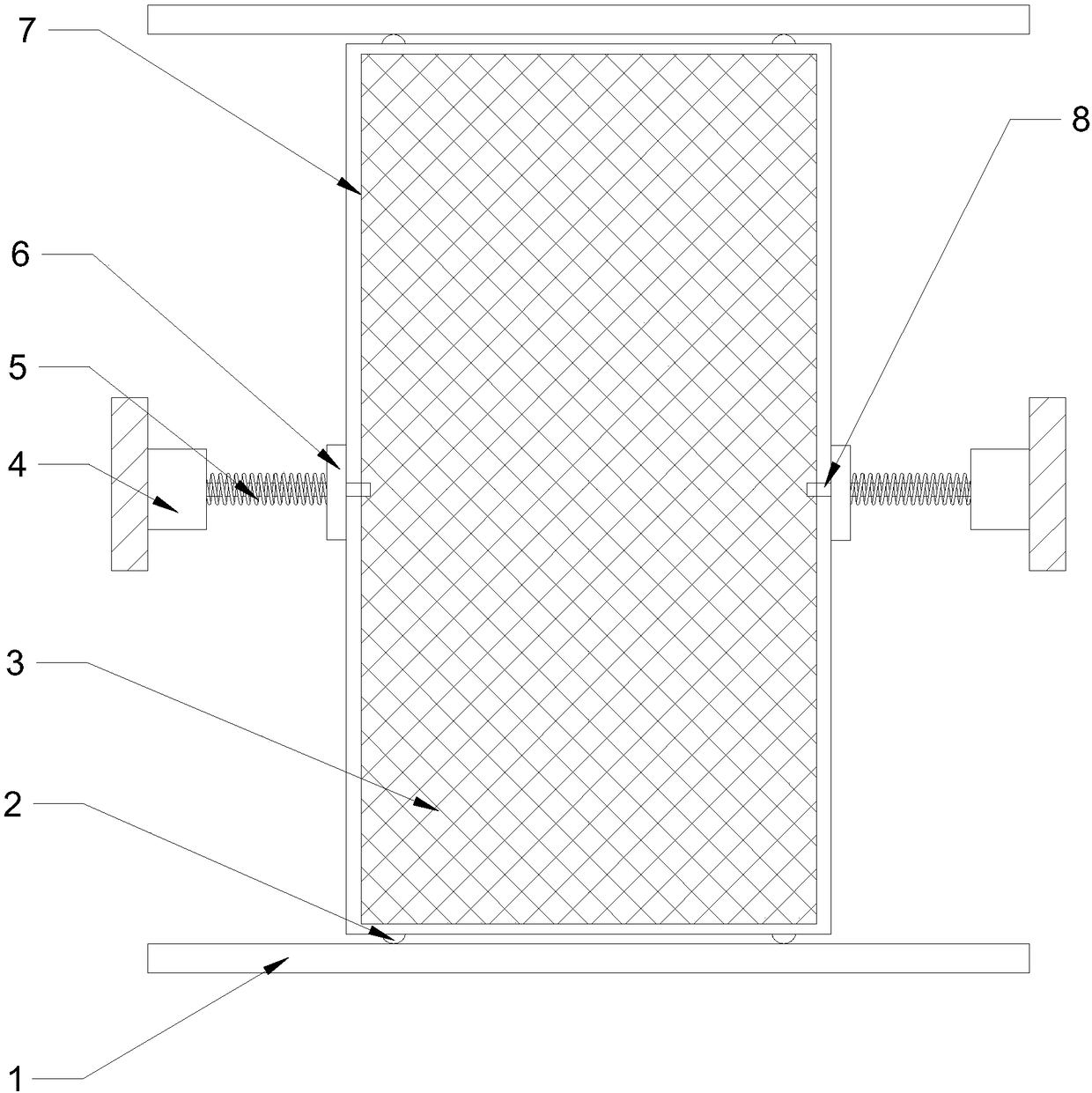

[0026] see Figure 1~2 , an electromagnetic type grain selection device, comprising a screen 3, the screen 3 is fixed on a screen frame 7, the screen frame 7 is a square frame, its opposite sides are provided with guide rails 1, and the guide rail 1 is opposite to the screen One side of the frame 7 is provided with a chute, the screen frame 7 is embedded in the chute of the guide rail 1, the other two sides of the screen frame 7 are fixed with magnets 6, and the side of the magnet 6 facing away from the screen frame 7 is provided with an electromagnet 4.

[0027] In this example, after the electromagnet 4 is energized, the coil in the electromagnet 4 produces an electromagnetic effect and generates magnetism. The magnet 6 and the electromagnet 4 on one side of the screen 3 have the same magnetic properties and repel each other, and the magnet 6 and the electromagnet 4 on the other side The magnetism is opposite to attract each other, and the magnetic force drives the screen f...

Embodiment 2

[0029] see Figure 1~2 , an electromagnetic type grain selection device, comprising a screen 3, the screen 3 is fixed on a screen frame 7, the screen frame 7 is a square frame, its opposite sides are provided with guide rails 1, and the guide rail 1 is opposite to the screen One side of the frame 7 is provided with a chute, the screen frame 7 is embedded in the chute of the guide rail 1, the other two sides of the screen frame 7 are fixed with magnets 6, and the side of the magnet 6 facing away from the screen frame 7 is provided with an electromagnet 4.

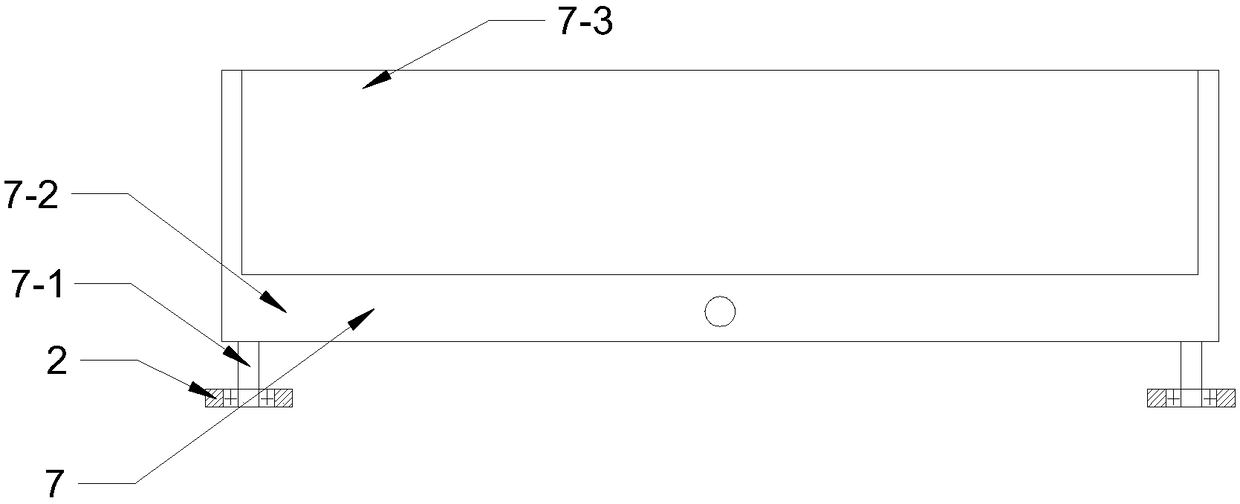

[0030] Screen frame 7 comprises screen frame 7-2, and screen frame 7-2 is a square frame, and the bottom of screen frame 7 is provided with pulley bar 7-1, and pulley bar 7-1 is provided with pulley 2, and pulley bar 7-1 There is a bearing between the pulley 2, the pulley 2 is embedded in the chute of the guide rail 1, and the pulley 2 is set between the screen frame 7 and the guide rail 1 to avoid sliding friction between ...

Embodiment 3

[0033] see Figure 1~2 , an electromagnetic type grain selection device, comprising a screen 3, the screen 3 is fixed on a screen frame 7, the screen frame 7 is a square frame, its opposite sides are provided with guide rails 1, and the guide rail 1 is opposite to the screen One side of the frame 7 is provided with a chute, the screen frame 7 is embedded in the chute of the guide rail 1, the other two sides of the screen frame 7 are fixed with magnets 6, and the side of the magnet 6 facing away from the screen frame 7 is provided with an electromagnet 4.

[0034] Screen frame 7 comprises screen frame 7-2, and screen frame 7-2 is a square frame, and the bottom of screen frame 7 is provided with pulley bar 7-1, and pulley bar 7-1 is provided with pulley 2, and pulley bar 7-1 A bearing is arranged between the pulley 2 and the pulley 2 is embedded in the chute of the guide rail 1.

[0035] The pulley 2 is laterally embedded in the chute of the guide rail 1 to prevent the screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com