A material crushing mechanism with double rotating grinding discs

A pulverizing mechanism and pulverizer technology, which is applied in the field of mechanical processing, can solve the problems of impurity particles, single structure, and incomplete pulverization of materials, and achieve the effects of reducing work loss, increasing service life, and reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

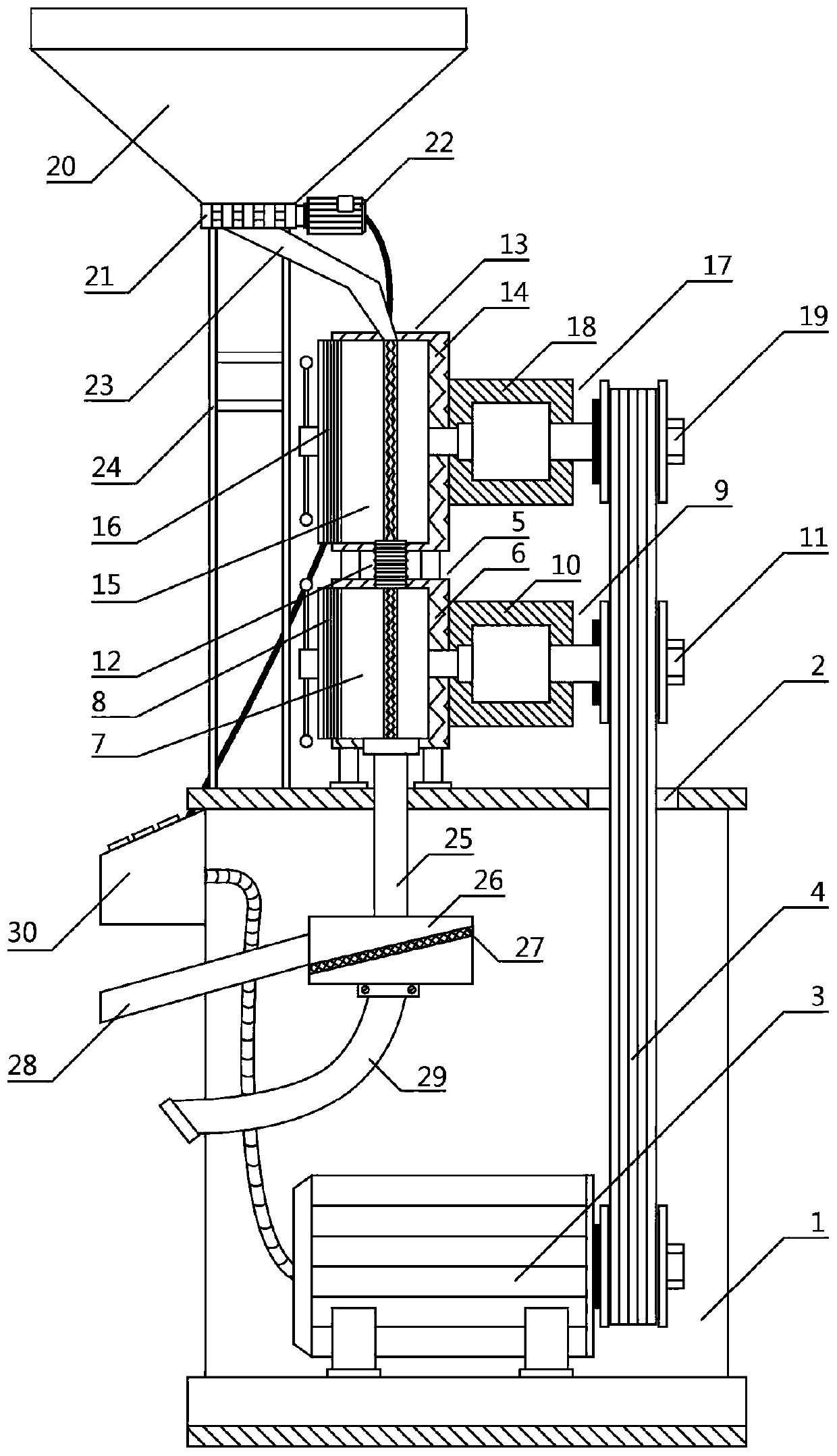

[0026] like figure 1A material crushing mechanism with double rotating grinding discs is shown, which is characterized in that it includes a cabinet 1, a drive motor 3, a transmission belt 4, a second grinder 5, a second grinder bearing 9, a second pulley 11, and a material connection Pipe 12, first pulverizer 13, first pulverizer bearing 17, first pulley 19, feed inlet 20, vibration device 21, feed conduit 23, bracket 24, discharge conduit 25, sub-sieve box 26, coarse material Output pipe 28, fine material output pipe 29 and console 30, described cabinet 1 is also provided with belt output port 2, and described belt output port 2 is positioned at the top of cabinet 1, and described belt output port 2 and cabinet 1 are fixed connected, the drive motor 3 is located inside the cabinet 1, the drive motor 3 is fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com