Semi direct drive permanent magnet motor

A permanent magnet motor, semi-direct drive technology, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of frequent replacement, belt wear, heavy maintenance workload, etc., and achieve cost saving, land occupation, and structure simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

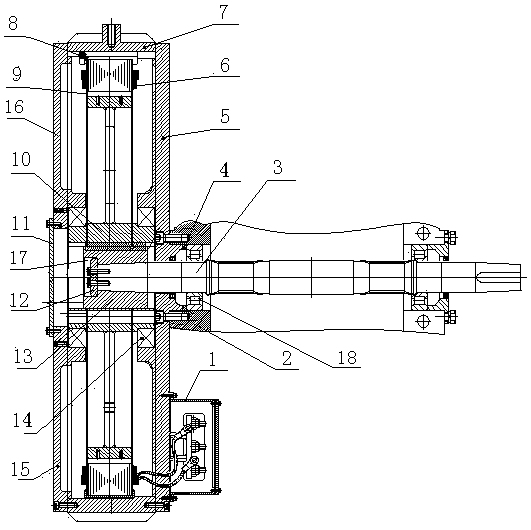

[0023] The structure of the semi-direct drive permanent magnet motor of the present invention is as follows: figure 1 As shown, the low-speed semi-direct drive permanent magnet motor is used to directly drive the reducer to run, and the original asynchronous motor, pulley and belt are cancelled. At the same time, according to its actual use, the motor structure is optimized. The main components of the semi-direct drive permanent magnet motor include: adjusting gasket 4, connecting end cover 5, motor stator 8, bushing 13, bushing baffle 12, motor rotor 10, Bearing 14 and end plate 15.

[0024] The specific structure is as follows: a motor stator 8 is installed on the inside of the motor housing 7, and a motor winding 6 is arranged on the motor stator 8. One end of the motor stator 8 is positioned on the connecting end cover 5 through a seam and fixed by screws, and the connecting end cover 5 is fixed by screws. Fixed on the reducer housing 2, the other end of the motor stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com