Automatic degassing device and method for separating dissolved gases in transformer oil sample

A technology for dissolving gas and transformer oil, applied in measuring devices, material separation, instruments, etc., can solve the problems of deviation of analysis results and low reliability of analysis data, and achieve the effect of avoiding operation deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

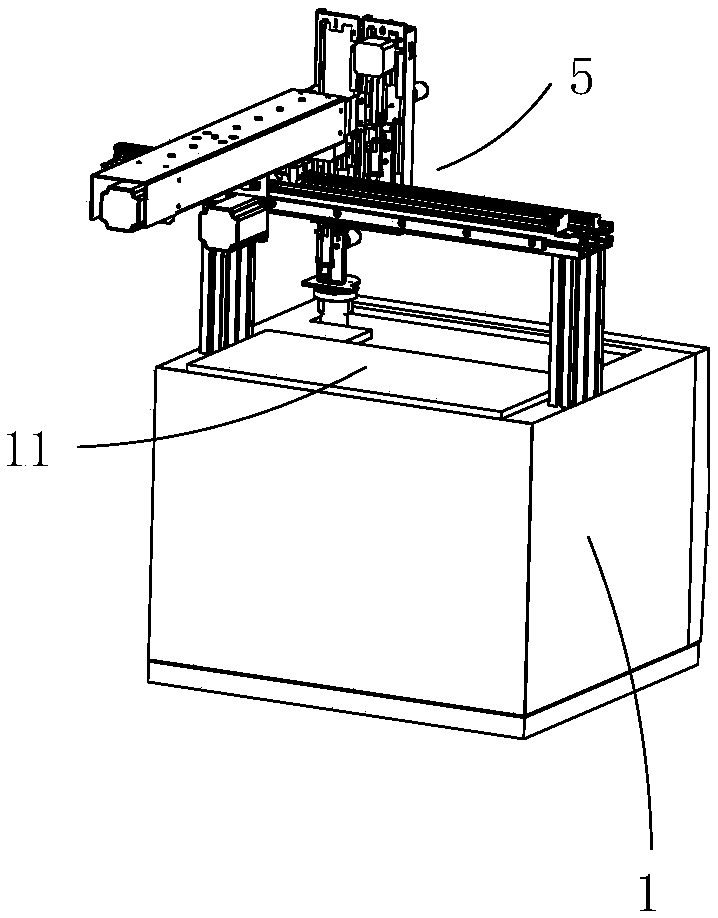

Examples

Embodiment approach

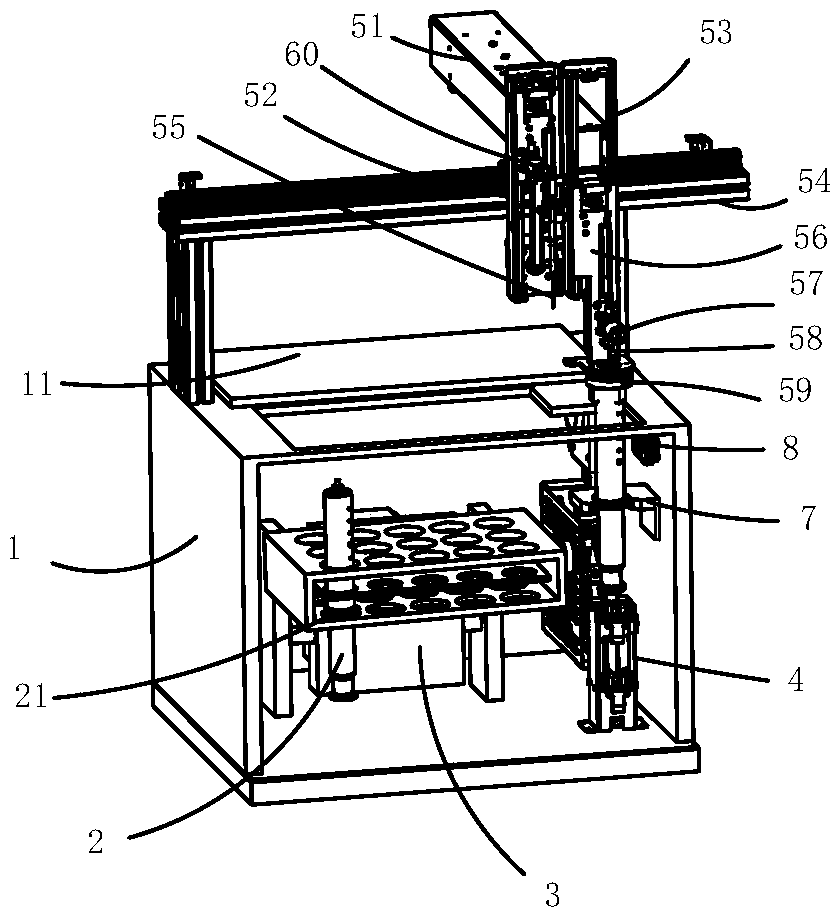

[0058] Further, see Figure 7 to Figure 10 , as a specific embodiment of the automatic degassing device for separating dissolved gas in transformer oil samples provided by the present invention, the oscillation tray 31 includes two layers of clamping tray bodies 311 and is arranged between the two layers of clamping tray bodies 311 The clamping tray body 312 that is slidably connected with the two layers of the clamping tray body, the clamping tray body 312 is connected with the locking mechanism 32, and the rotary stepping motor 34 is connected with the clamping tray body 311 connected, the clamping tray body 312 corresponds to the holes 37 provided on the two layers of the clamping tray body 311 one by one, and the clamping tray body slides left and right under the action of the locking mechanism, so that all The holes on the clamping tray body and the holes on the clamping tray body are misaligned to clamp the sealed container. In this embodiment, the clamping of the airti...

specific Embodiment

[0075] A specific embodiment of the automatic degassing method provided by the invention is as follows:

[0076] 1. The equipment is powered on and stable.

[0077] Use a unified customized 100mL sealed glass syringe to hold the insulating oil sample. For the sake of uniformity, the sealed glass syringe containing the oil sample is called the sealed container 2, and the insulating oil sample is placed in the mechanical vibration tray 31, and the sample loaded into the sealed container 2 is required The volume is greater than or equal to the set value of 40mL, and it is ensured that no air bubbles are introduced into the airtight container 2 . The sample tray can hold up to 15 samples at a time. A 60mL sealed glass syringe can also be used as the sealed container 2.

[0078] 2. Automatically adjust the volume of test oil

[0079] After the equipment installation and setting program is started, firstly, the three-dimensional manipulator grabs the sealed container 2 in order a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com