Tightness test and evaluation method for high-density polyethylene tubes for nuclear power stations

A technology of high-density polyethylene and tightness test, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., can solve the problem that the tightness test and evaluation method of HDPE pipe used in nuclear power plants has not been formed And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

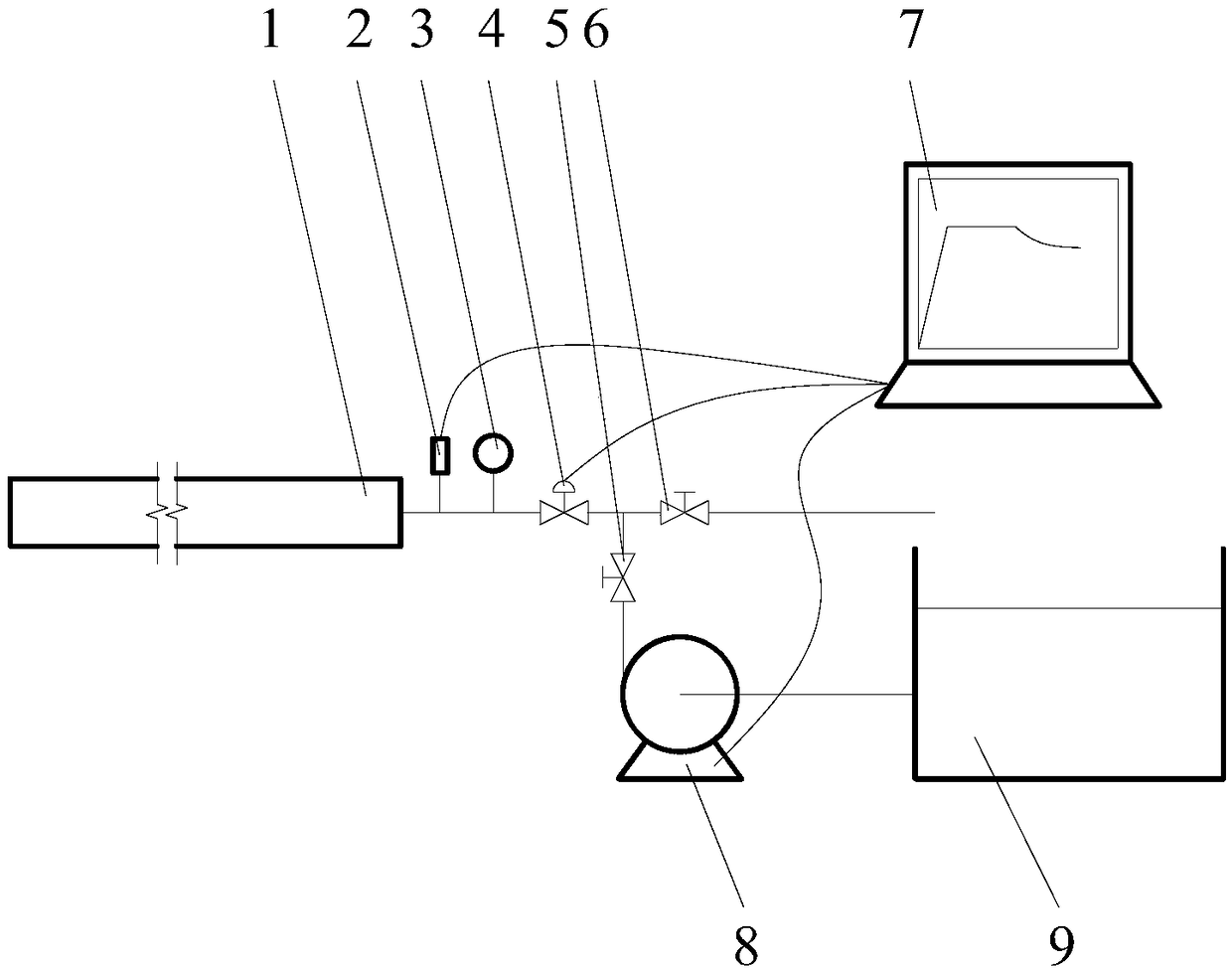

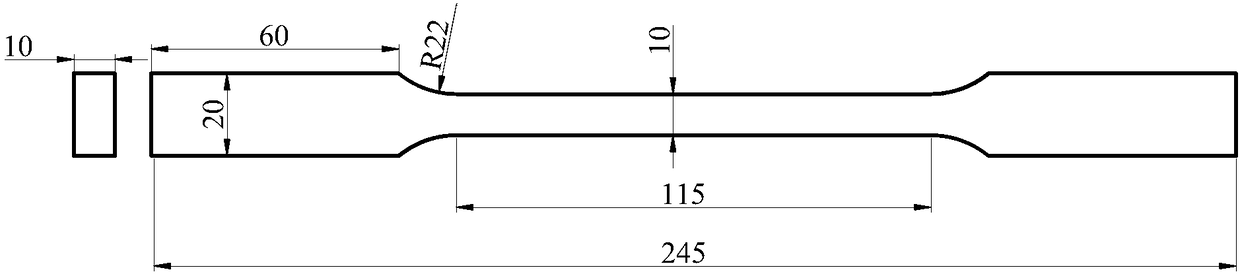

Method used

Image

Examples

Embodiment

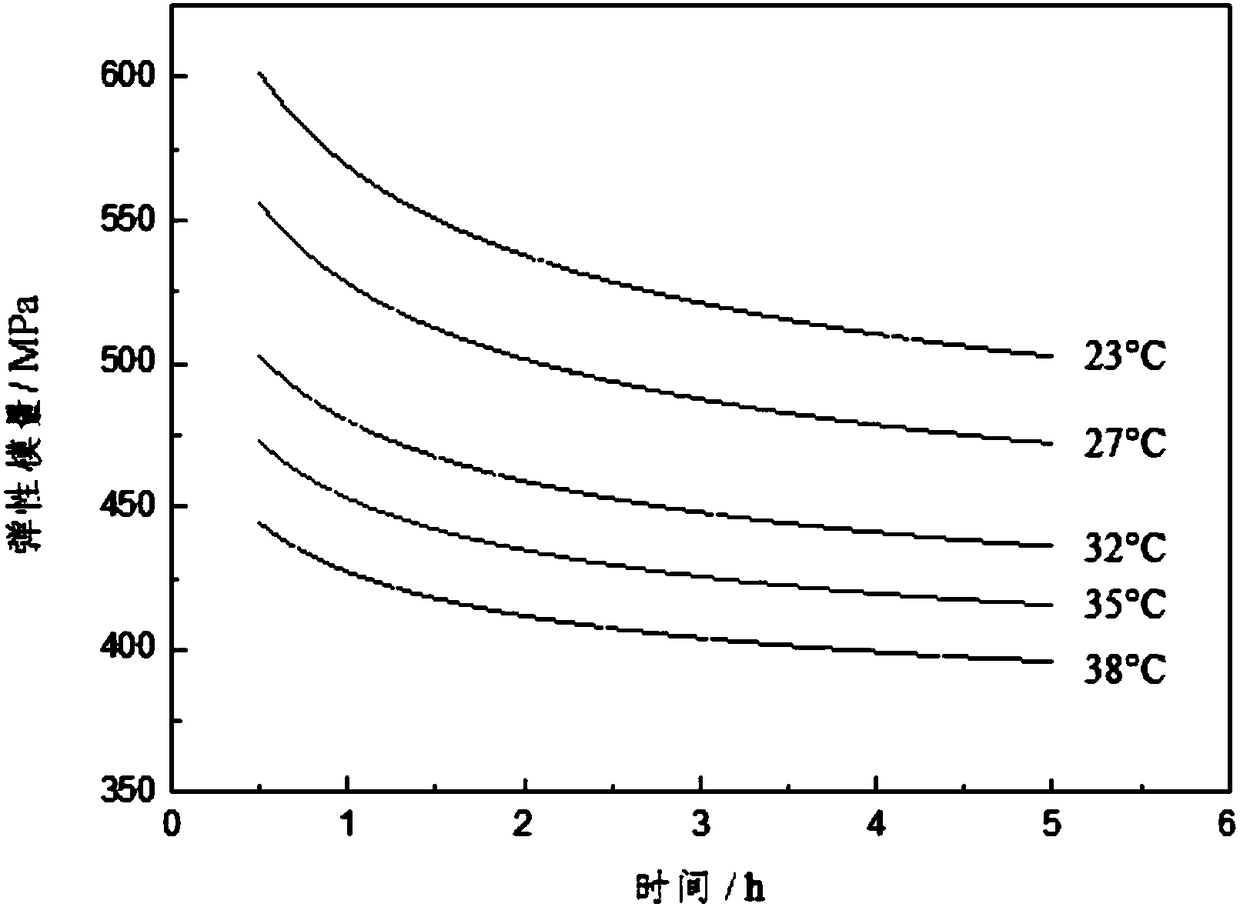

[0069] According to the tightness test and evaluation method for HDPE pipes used in nuclear power plants provided by the present invention, the tightness test can be carried out on the laid HDPE pipes with a length of 1 km. If the section of pipe is an HDPE pipe with an outer diameter of 762 mm and DR9, the test pressure is 2.60 MPa, and the field test temperature is 23° C., according to the steps (1) to (4) of the method of the present invention, the actual pressure drop can be obtained.

[0070] The allowable pressure drop of HDPE pipe obtains according to step (5) of the present invention:

[0071] Step A, calculate the modulus E(t) of the HDPE pipe at any time

[0072] At the on-site test temperature of 23°C, the obtained relaxation modulus data is fitted, and the modulus of the HDPE pipe at any time can be obtained as:

[0073]

[0074] In the formula, t is the test time, unit h; E(t) is the modulus of HDPE pipe at any time, unit MPa;

[0075] Step B, calculate HDPE ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com