Oil pump and oil cylinder integrated device driven by alternating current servo motor

A technology of AC servo motor and motor pump, which is applied in the direction of fluid pressure actuating device, etc., which can solve the problems of non-concentric motor shaft and pump shaft, inconvenient installation and use, and low energy utilization rate, so as to achieve expanded working capacity and sensitive response , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings.

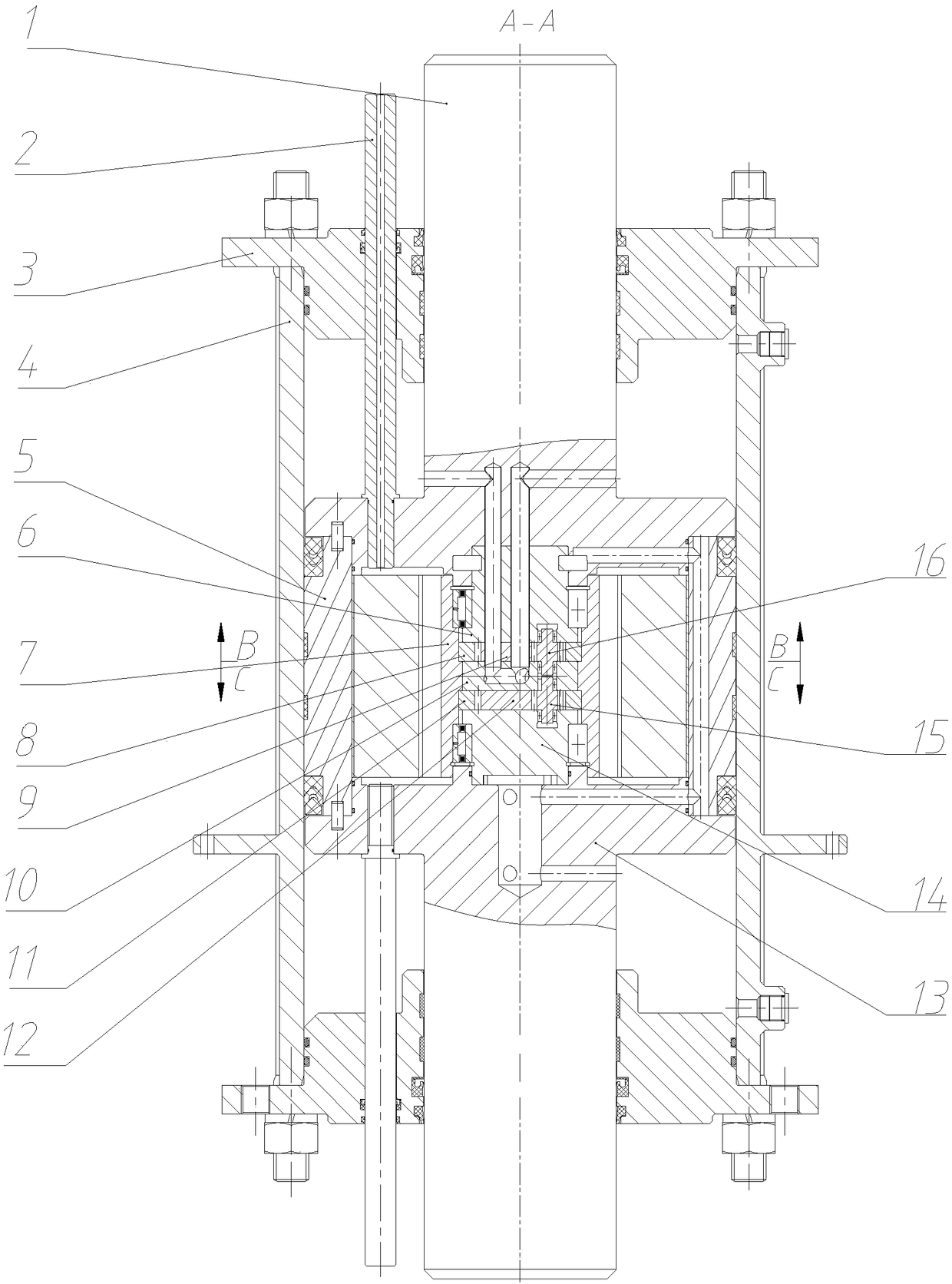

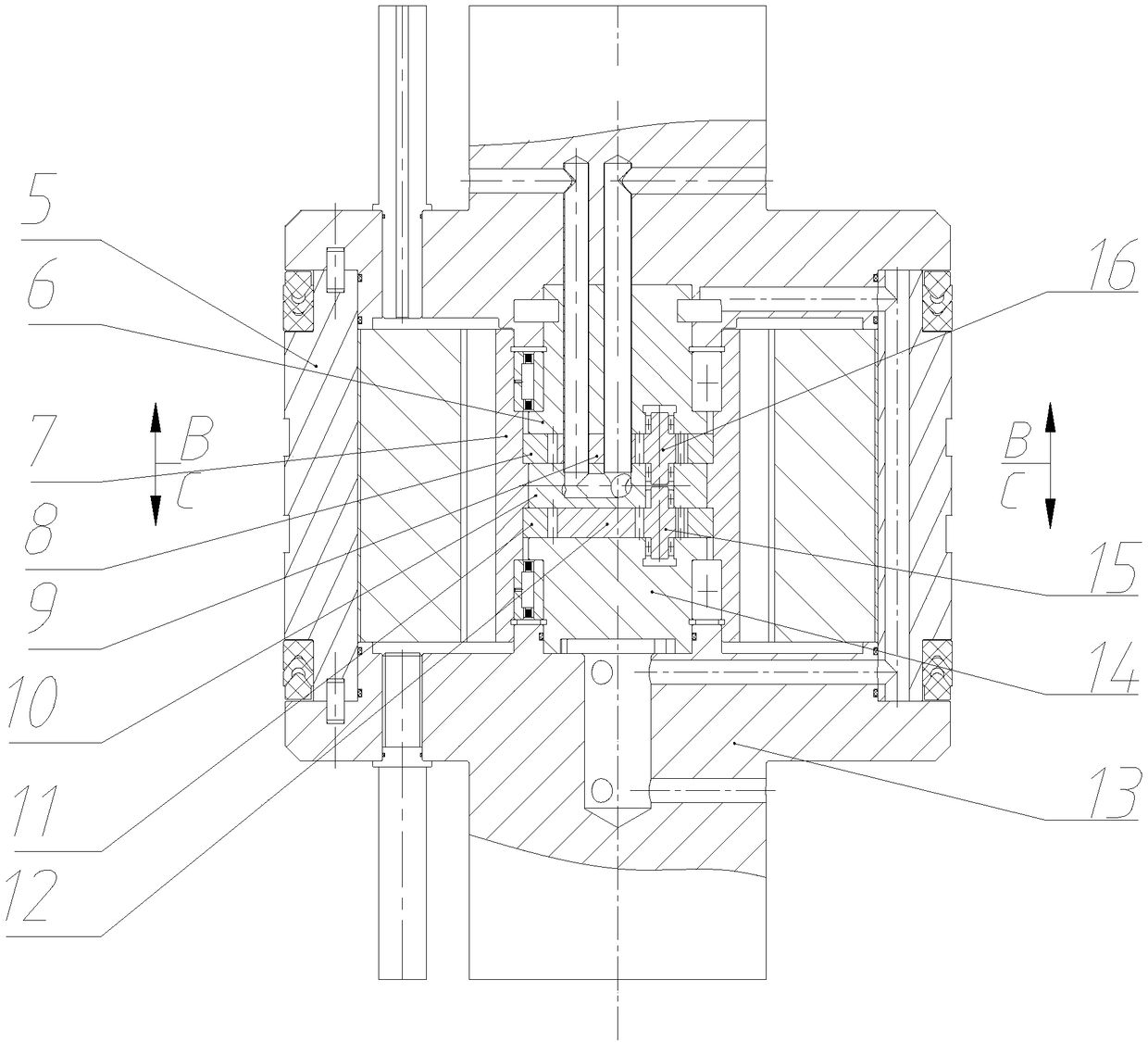

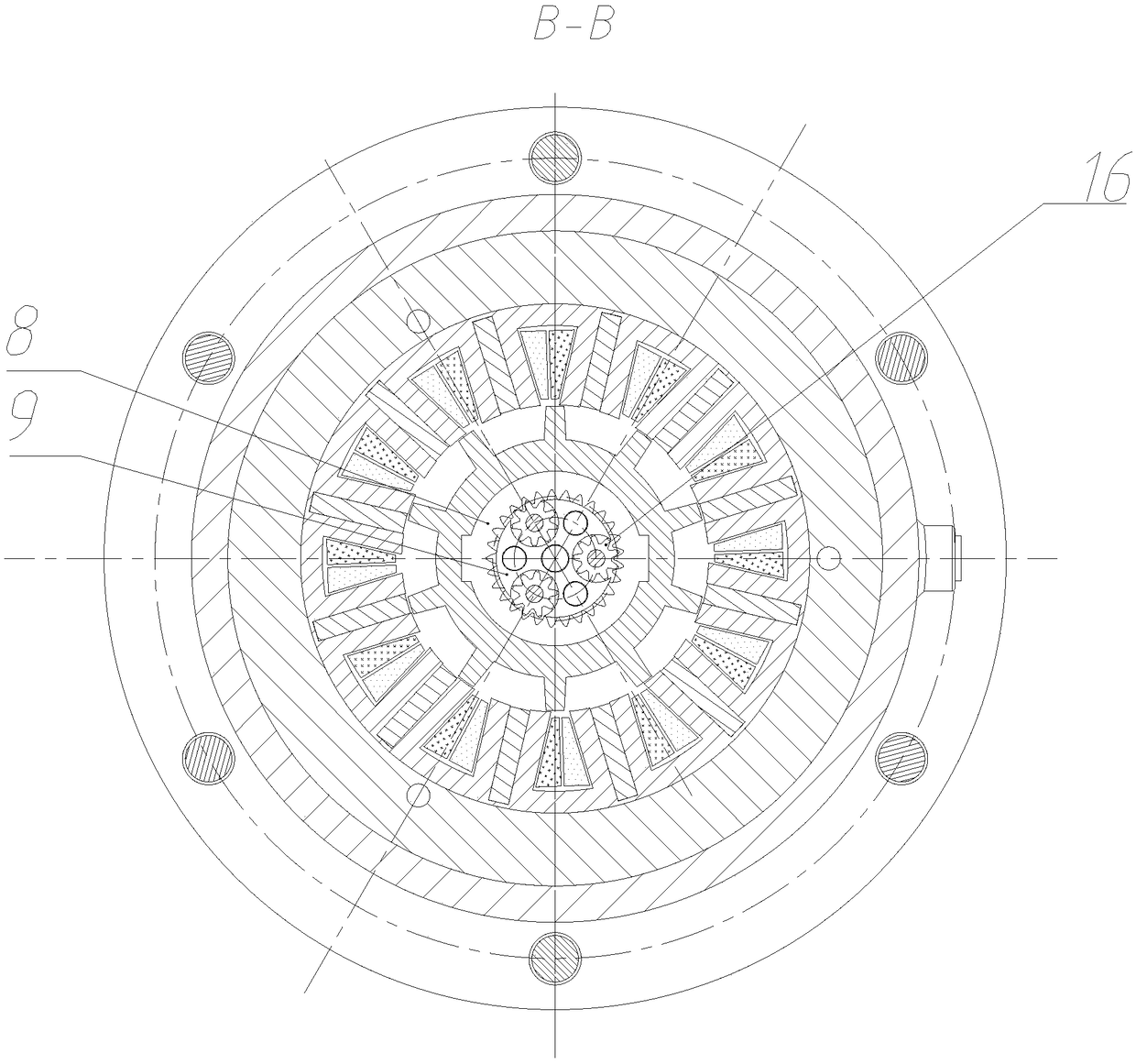

[0024] refer to figure 1 , an AC servo motor-driven oil pump and oil cylinder integration device, including a hydraulic cylinder barrel 4, the middle of the hydraulic cylinder barrel 4 is provided with a piston ring 5, the interior of the piston ring 5 is connected with a two-way double internal meshing gear motor pump, bidirectional The two outputs of the double internal meshing gear motor pump are respectively connected with the first piston rod 1 and the second piston rod 13. The first piston rod 1 and the second piston rod 13 are respectively connected with the piston ring 5 through countersunk screws, and are aligned with pins. , the first piston rod 1 is connected, the second piston rod 13 is connected with the piston ring 5 in the oil circuit, and the piston ring 5 moves on the inner wall of the cylinder 4 after being sealed by the combined sealing ring and guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com