Pressure-variable dredging method for high-level drilling gas channel

A high-level drilling and gas channel technology, which is used in gas discharge, earth-moving drilling, safety devices, etc., can solve the problems of blocking gas flow channels and gas rise, and achieves the effects of low labor intensity, short time and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for dredging a high-level borehole gas channel with variable pressure, comprising the following steps,

[0019] a. First, carry out high-level drilling on the coal mining face, that is, drill holes to the coal seam roof in the return airway of the working face, design several drilling sites, and a single group of drilling sites contains 10 drilling holes;

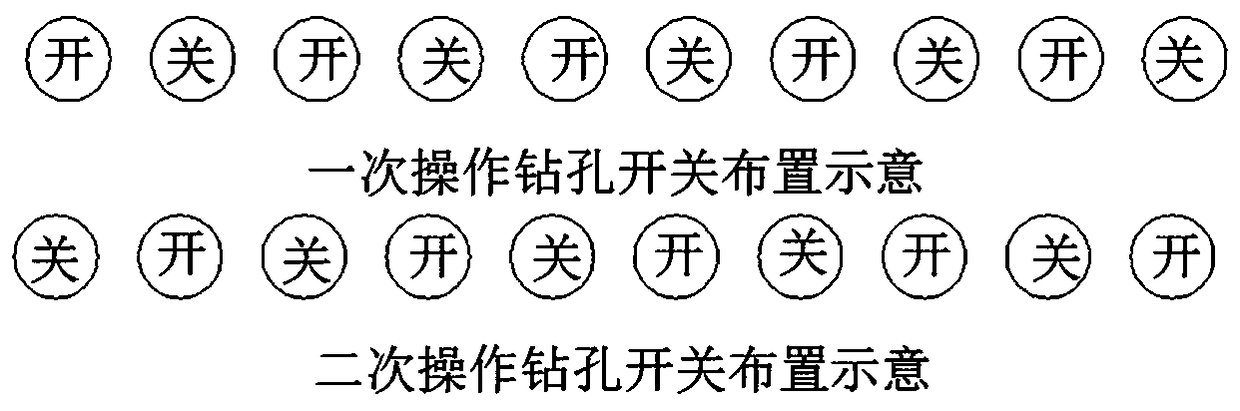

[0020] b. Close the drainage drilling valve at the drilling site at intervals for 10 minutes;

[0021] c. The borehole that was closed for the first time is opened, and the unclosed borehole is closed. The duration is that there is an obvious sound of falling stones in the drainage pipeline at the initial stage, and it will stop when the sound fades away;

[0022] d. Repeat steps b and c above for 2-3 times.

[0023] The duration of step c is 10 min.

[0024] In step a, 8 drilling sites are designed, and a single group of drilling sites contains 10 drilling holes, a total of 80 drilling holes.

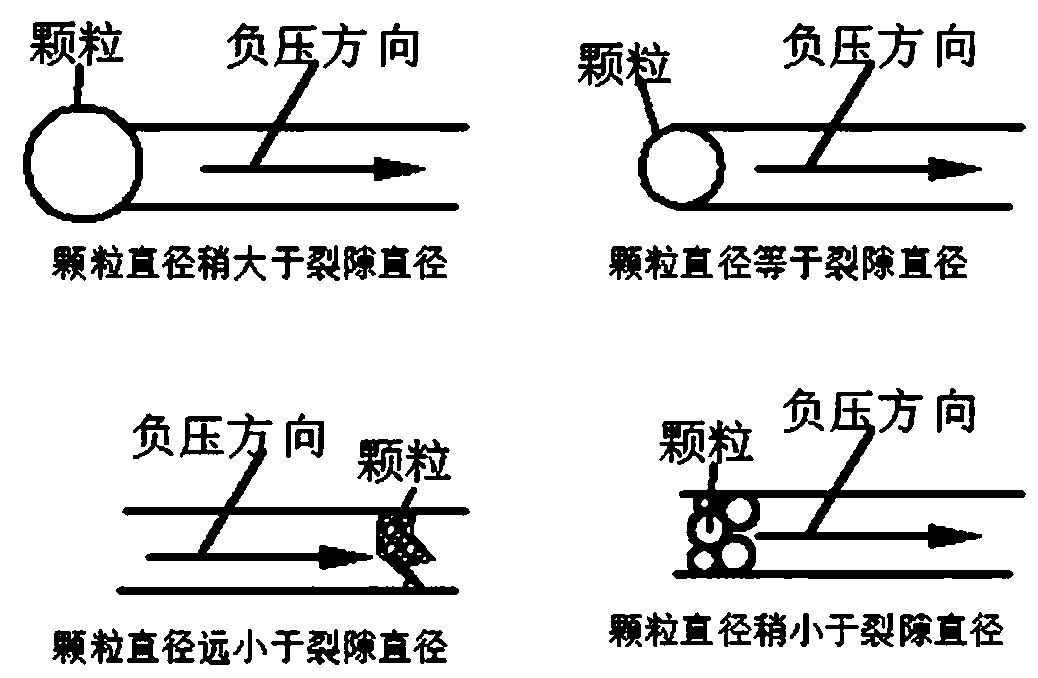

[0025] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com