High-performance steel bridge deck structure

A steel bridge deck, high-performance technology, used in bridges, bridge parts, bridge materials, etc., can solve problems such as weak lateral stiffness, reduce fatigue stress, improve structural properties, and reduce maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

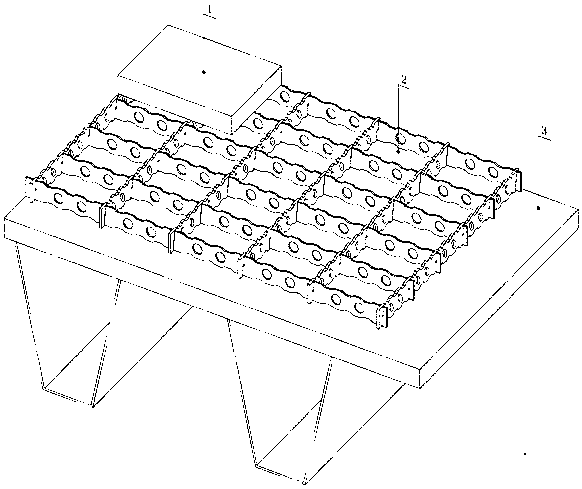

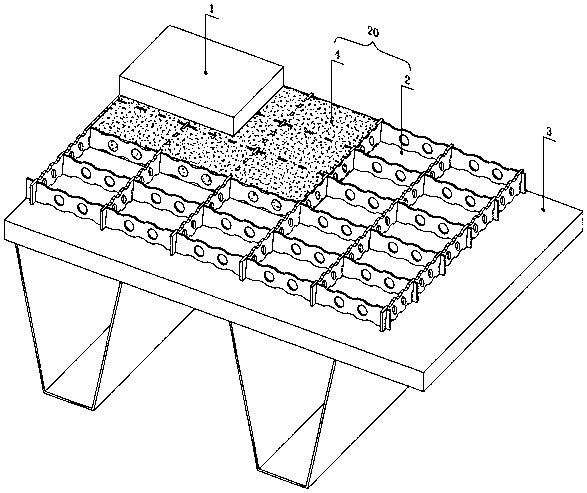

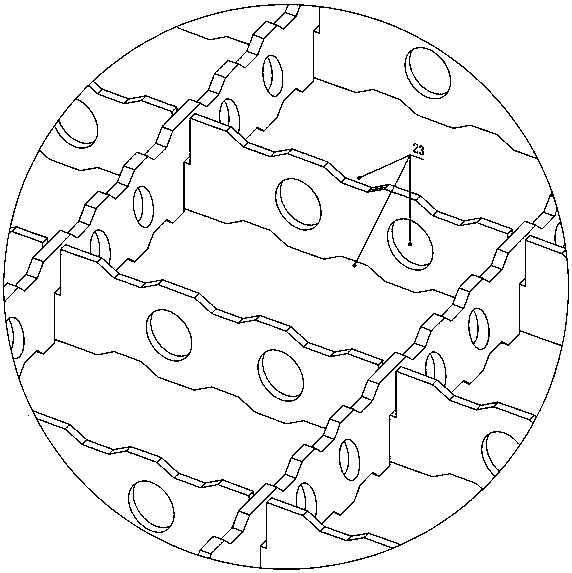

[0033] Such as Figure 1-Figure 5 As shown, the specific structure of the present invention is as follows: comprising a bridge deck surface layer 1 on the top layer, a grid layer 20 in the middle, and an orthotropic steel bridge deck 3 on the bottom layer, and the grid layer 20 is composed of partitions 21 Composed cell 2 and filler 4 filled in the cell 2. The bridge surface layer 1 is asphalt concrete, the partition plate 21 is metal material, and the filling material 4 is active powder concrete. Asphalt concrete and reactive powder concrete can bond better, which improves the problem of insufficient bonding adhesion between asphalt concrete bridge deck surface and orthotropic steel bridge deck.

[0034] The bridge deck surface layer 1 is the bridge deck pavement layer, which generally includes a waterproof layer, an adhesive layer, a wear layer and the like. The orthotropic steel bridge deck 3 refers to a traditional orthotropic steel bridge deck, which is composed of a st...

Embodiment approach 2

[0040] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the cell 2 is hexagonal in plan view.

[0041] Beneficial effects of the present invention:

[0042] 1. The traditional orthotropic steel deck structure is improved, and the newly added grid layer improves the rigidity and strength of the steel deck and reduces the risk of fatigue damage of the steel deck. After the bridge is completed, only the surface of the bridge deck needs to be repaired regularly, and other parts of the bridge deck generally do not need to be maintained, thus reducing the maintenance cost of the steel bridge deck.

[0043] 2. The newly added grid layer can assist the load bearing of the orthotropic steel bridge deck, can effectively improve the stiffness and strength of the bridge deck, significantly reduce the fatigue stress of the steel deck, prolong the service life of the orthotropic steel bridge deck, and significantly improve the strength of the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com