Multifunctional clean drag reducing agent used for shale gas fracturing and preparation method of drag reducing agent

A drag reducer and multifunctional technology, which is applied in the field of multifunctional clean drag reducer for shale gas fracturing and its preparation, can solve the problems of heavy workload, high cost, and complicated on-site liquid preparation operations, and avoid damage , reduce friction, reduce the effect of on-site construction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

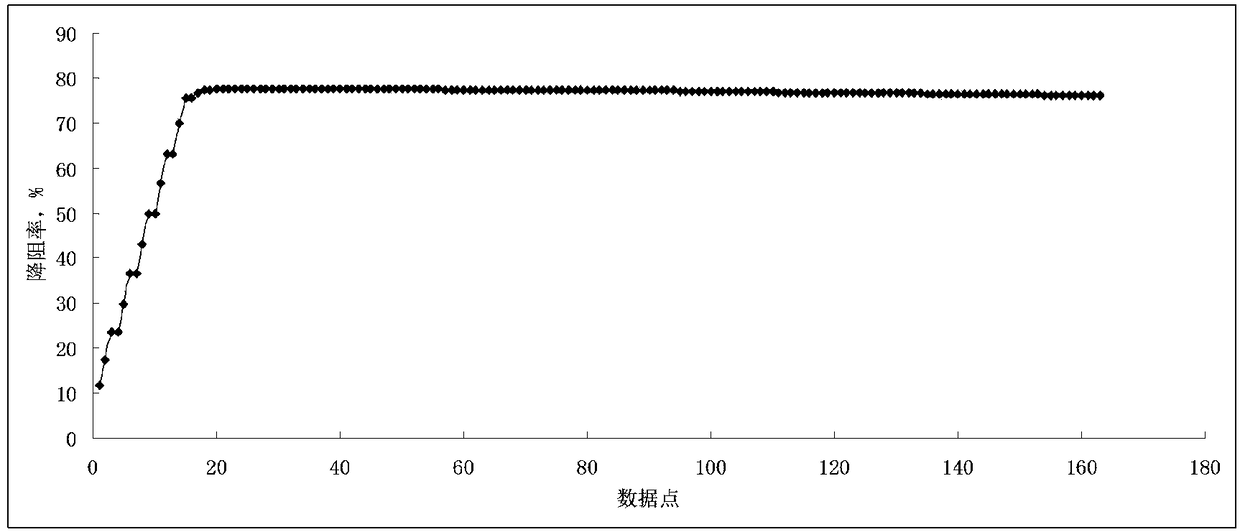

Image

Examples

Embodiment 1

[0029] The specific operation steps for preparing 1000g of multifunctional cleaning drag reducer for fracturing are as follows:

[0030] S1, external phase preparation: 80g glycerol carbonate and 100g allyl polyoxyethylene ether (structural formula CH 2 =CHCH 2 O(CH 2 CH 2 O) 4 H) Mix and stir evenly, set aside.

[0031] S2. Internal phase preparation: add 100g (2-acryloyloxy)ethoxybenzyltriethylammonium chloride, 50g N-vinylpyrrolidone, and 150g potassium formate into 519.98g of water, stir and dissolve evenly, and set aside .

[0032] S3. Emulsion polymerization: Pour the prepared external phase into the reaction vessel, then place the reaction vessel in a constant temperature water bath at 20-25°C, turn on the agitator, and slowly add the prepared internal phase solution into the external phase to form a Lotion base. Simultaneously pass nitrogen gas and stir at high speed to remove oxygen. After stirring for 20min-40min, add 0.01g of ammonium persulfate and 0.01g of ...

Embodiment 2

[0034] The specific operation steps for preparing 1000g of multifunctional cleaning drag reducer for fracturing are as follows:

[0035] S1, external phase preparation: 120g glycerol carbonate and 60g allyl polyoxyethylene ether (structural formula CH 2 =CHCH 2 O(CH 2 CH 2 O) 20 H) Mix and stir evenly, set aside.

[0036] S2. Internal phase preparation: add 140g of (2-acryloyloxy)ethoxybenzyltriethylammonium chloride, 79.9g of N-vinylpyrrolidone, and 200g of sodium acetate into 400g of water, stir and dissolve evenly, and set aside.

[0037] S3. Emulsion polymerization: Pour the prepared external phase into the reaction vessel, then place the reaction vessel in a constant temperature water bath at 20-25°C, turn on the agitator, and slowly add the prepared internal phase solution into the external phase to form a Lotion base. Simultaneously pass nitrogen gas at high speed and stir to remove oxygen. After stirring for 20min-40min, add 0.1g ammonium persulfate initiator int...

Embodiment 3

[0039] The specific operation steps for preparing 1000g of multifunctional cleaning drag reducer for fracturing are as follows:

[0040] S1, external phase preparation: 100g glycerol carbonate and 80g allyl polyoxyethylene ether (structural formula CH 2 =CHCH 2 O(CH 2 CH 2 O) 12 H) Mix and stir evenly, set aside.

[0041] S2. Internal phase preparation: add 120g (2-acryloyloxy)ethoxybenzyltriethylammonium chloride, 59.95g N-vinylpyrrolidone, and 180g sodium citrate into 460g of water, stir and dissolve evenly, and set aside .

[0042]S3. Emulsion polymerization: Pour the prepared external phase into the reaction vessel, then place the reaction vessel in a constant temperature water bath at 20-25°C, turn on the agitator, and slowly add the prepared internal phase solution into the external phase to form a Lotion base. Simultaneously pass nitrogen gas at high speed and stir to remove oxygen. After stirring for 20min-40min, add 0.05g of sodium bisulfite initiator into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com