Preparation method of nano composite wave-absorbing material

A wave-absorbing material and nano-composite technology, which is applied in the field of wave-absorbing materials, can solve problems such as increasing loss and enhancing the magnetic loss of composite materials, and achieve good wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

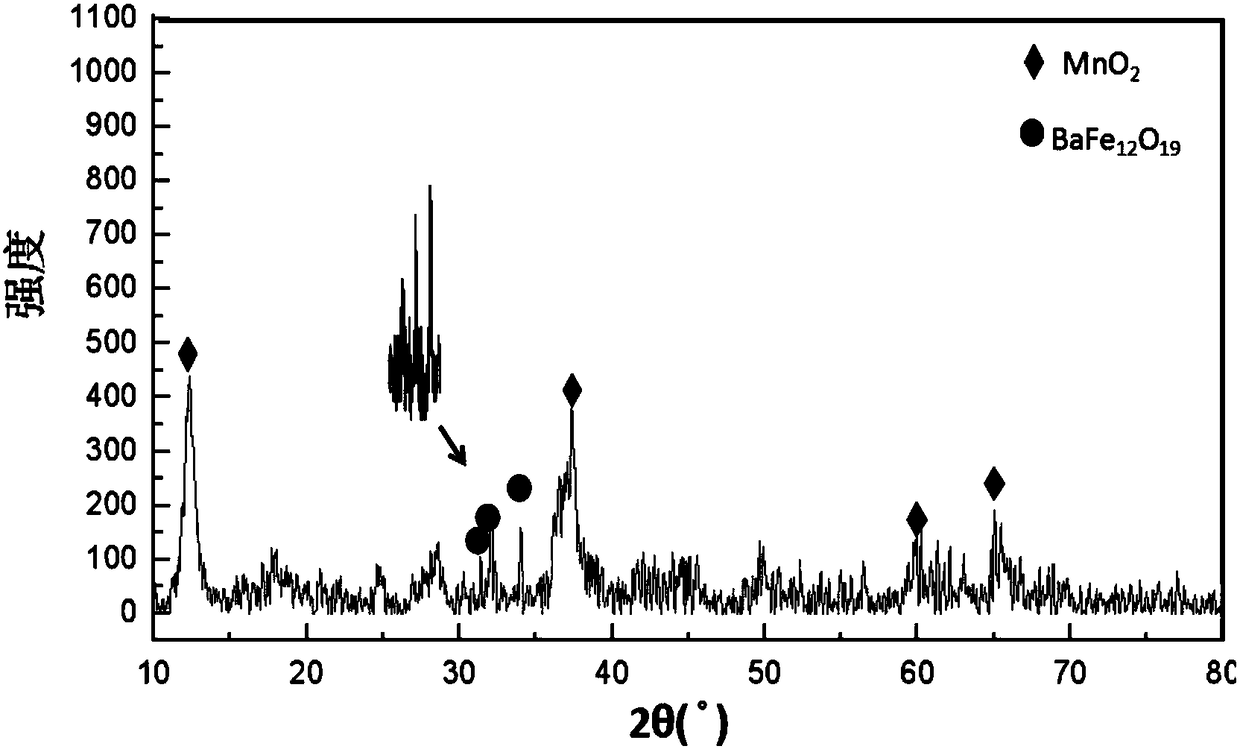

[0029] (1) Preparation of barium ferrite nanoparticles: Dissolve 0.5g of barium nitrate and 5.09g of ferric nitrate in deionized water, then slowly add to the mixed solution of sodium hydroxide and sodium carbonate (2.6g of sodium hydroxide and 0.3g of carbonic acid Dissolve sodium in distilled water (mixed solution), stir evenly, adjust pH to 13, then continue to stir for 5 hours, wash the obtained precipitate with distilled water and ethanol respectively, dry at 60°C for 24h to obtain a precursor, and calcinate the precursor at 900°C for 3h, Obtain barium ferrite nanoparticles;

[0030] (2) Preparation of barium ferrite / manganese dioxide nanospheres: Weigh 0.1 g of barium ferrite nanoparticles prepared in step (1), add 1 g of potassium permanganate, and then add deionized water to prepare 50 mL of After the solution is uniformly dispersed, 1.5mL of concentrated hydrochloric acid solution with a mass concentration of 37% is added dropwise, stirred evenly, then heated to 100°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com