Wind energy-driven organic fertilizer stirring device

A technology of organic fertilizer and stirring device, which is applied in the direction of organic fertilizer, organic fertilizer equipment, mixer with rotating stirring device, etc. It can solve the problems of inability to meet the requirements of large-scale organic waste treatment, small production volume and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

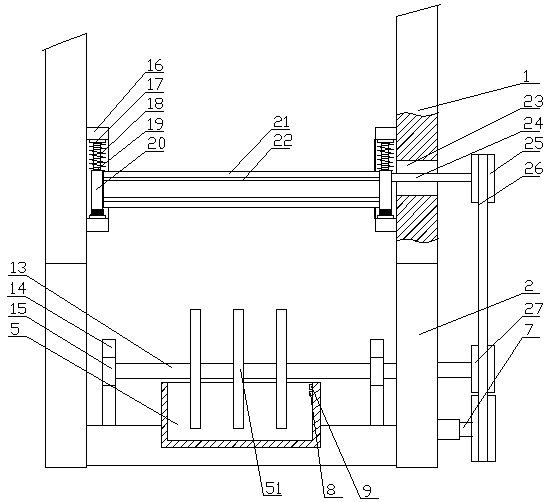

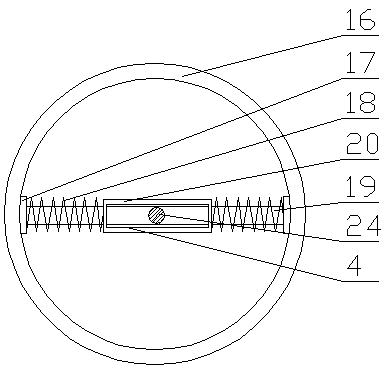

[0056] Embodiment 1. This embodiment provides an organic fertilizer stirring device driven by wind energy, including a fermentation tank 5, and two ends of the fermentation tank 5 are provided with a reinforced concrete U-shaped frame 2, and the U-shaped frame 2 A reinforced concrete first column 1 is arranged at the upper end, and a wind-driven rotating mechanism 3 is arranged on the first column 1. A stirring mechanism 6 is arranged in the fermentation tank 5. The wind-driven rotating mechanism 3 and the stirring mechanism 6 pass through a transmission mechanism. Transmission connection, a heating and ventilating mechanism is arranged above the fermentation tank 5, and a first driving motor 43 is set on the side of the U-shaped frame 2 corresponding to the stirring mechanism 6. The first driving motor 43, transmission mechanism, heating and ventilating The mechanism is signal-connected with the control mechanism.

[0057] The raw materials for making organic fertilizer are p...

Embodiment 2

[0064] Embodiment 2, which is different from Embodiment 1 in that: the transmission mechanism includes a belt 26 provided on the first drive disc 25 and the second drive disc 27, corresponding to the belt 26 on the first column 1 Tensioning mechanism 7 is set on.

[0065] The tensioning mechanism 7 includes a translation mechanism 36 provided on the U-shaped frame 2 at one end of the fermentation tank 5 provided with a second drive disc 27, and the translation mechanism 36 is located below the second drive disc 27, A tension disc 28 is arranged on the translation mechanism 36, and the diameter of the tension disc 28 is larger than that of the second driving disc 27. Platform 29, the third bearing 30 is set on the described installation platform 29, leading screw 32 is arranged in the described third bearing 30, guide bar 33 parallel with described leading screw 32 is set between described installation platform 29, described screw A translation base 34 is set on the bar 32 and...

Embodiment 3

[0067] Embodiment 3, which differs from Embodiment 1 in that: a steel second column 44 is set corresponding to the first column 1 on the right side on the ground, and the second column 44 corresponds to the rotation shaft 13 through the first telescopic The mechanism 41 is provided with the first driving motor 43, the output shaft of the first driving motor 43 is provided with a first gear disc 45, and the end of the rotating shaft 13 protrudes from the second driving disc 27 corresponding to the first gear disc 45. A gear plate 45 is provided with a second gear plate 38, and the first telescopic mechanism 41 adopts a hydraulic telescopic rod. The second column 44 is reinforced by an angle iron 39, and the angle iron 39 is provided with a card slot 42 that cooperates with the first telescopic mechanism 41. There are two angle irons 39 that cooperate with each other. Mechanism 41 is connected to the control mechanism.

[0068] The first drive mechanism needs to be set correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com