Iron tailing sand concrete and preparation method thereof

A technology of iron tailings sand and concrete, which is applied in the field of construction concrete, can solve the problems of iron tailings pollution, high concrete cost, and difficult treatment, and achieve the effects of strong practicability, pollution reduction, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

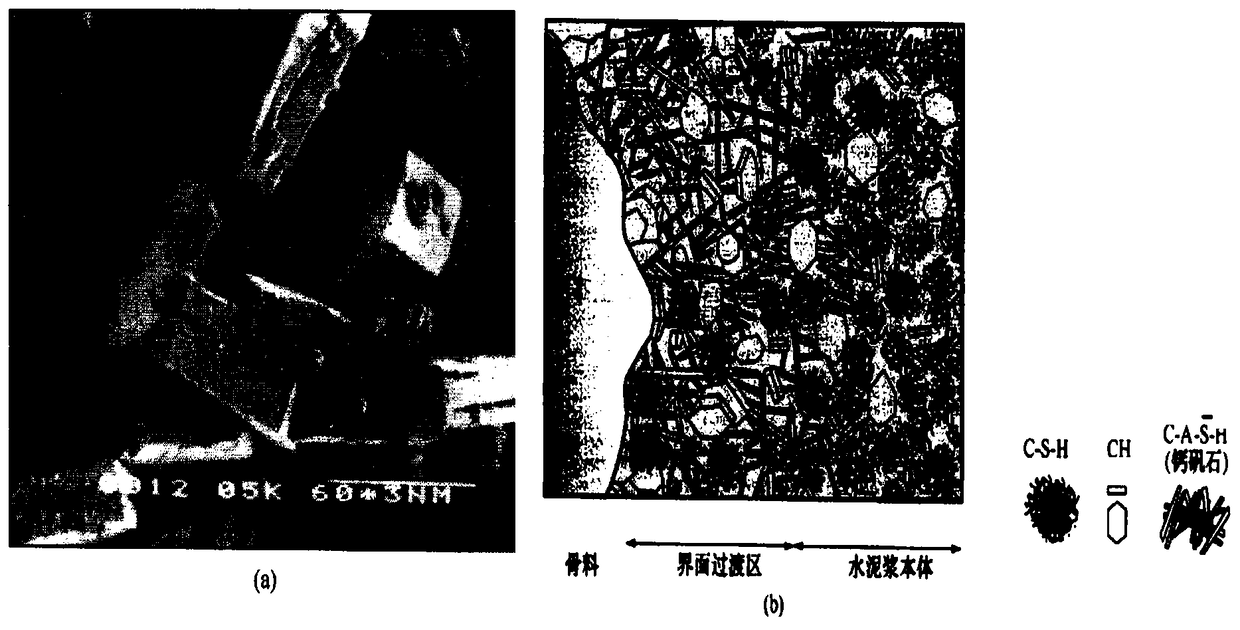

Image

Examples

Embodiment 1

[0025] Embodiment 1: A kind of iron tailings sand concrete is made of the following raw materials: 20 kg of tailings balls, 10 kg of tailings powder, 5 kg of cement, and 2 kg of water; the tailings balls are made of the following weights of raw materials: 8 kg of cement, Tailings powder 36kg, water 17.6kg, polycarboxylic acid 1.6kg, rubber powder 0.24kg.

[0026] A preparation method for iron tailings sand concrete, comprising the following steps:

[0027] A. Preparation of tailings balls

[0028] A1: Weighing raw materials

[0029] The raw materials were weighed according to the following parts by weight: 8 kg of cement, 36 kg of tailings powder, 17.6 kg of water, 1.6 kg of polycarboxylic acid, and 0.24 kg of rubber powder; wherein the tailings powder had a particle size of 200 mesh and was obtained through ore grinding;

[0030] A2: Roll mixing

[0031] Dry mix the cement and tailings powder weighed in step A1, the mixing speed is 15r / min, and the stirring time is 20 minu...

Embodiment 2

[0037] Embodiment 2: A kind of iron tailings sand concrete is made of the following raw materials: 40 kg of tailings balls, 20 kg of tailings powder, 15 kg of cement, and 6 kg of water; the tailings balls are made of the following raw materials: 12 kg of cement, 36kg。 Tailings powder 48kg, water 24kg, water reducing agent 2.4kg, rubber powder 0. 36kg.

[0038] A preparation method for iron tailings sand concrete, comprising the following steps:

[0039] A. Preparation of tailings balls

[0040] A1: Weighing raw materials

[0041] The raw materials were weighed according to the following parts by weight: 12kg of cement, 48kg of tailings powder, 24kg of water, 2.4kg of water reducing agent, and 0.36kg of rubber powder; wherein the tailings powder has a particle size of 200 mesh and is obtained through ore grinding;

[0042] A2: Roll mixing

[0043] Dry mix the cement and tailings powder weighed in step A1. The mixing speed is 15r / min, and the stirring time is 20 minutes. Afte...

Embodiment 3

[0049] Embodiment 3: a kind of iron tailings sand concrete is made of the following raw materials: 40 kg of tailings balls, 20 kg of tailings powder, 15 kg of cement, and 6 kg of water; the tailings balls are made of the following raw materials: 12 kg of cement, 36kg。 Tailings powder 48kg, water 24kg, polycarboxylate 2.4kg, rubber powder 0. 36kg.

[0050] A preparation method for iron tailings sand concrete, comprising the following steps:

[0051] A. Preparation of tailings balls

[0052] A1: Weighing raw materials

[0053] Weigh the raw materials according to the following parts by weight: 12kg of cement, 48kg of tailings powder, 24kg of water, 2.4kg of water reducing agent, and 0.36kg of rubber powder; wherein the tailings powder has a particle size of 200 mesh and is obtained by grinding ore;

[0054] A2: Roll mixing

[0055]Dry mix the cement and tailings powder weighed in step A1. The mixing time is 20 minutes. After mixing evenly, add water for wet mixing. The mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com