A facile and controlled synthesis of sea urchin-like graphene spheres by water-in-oil emulsion

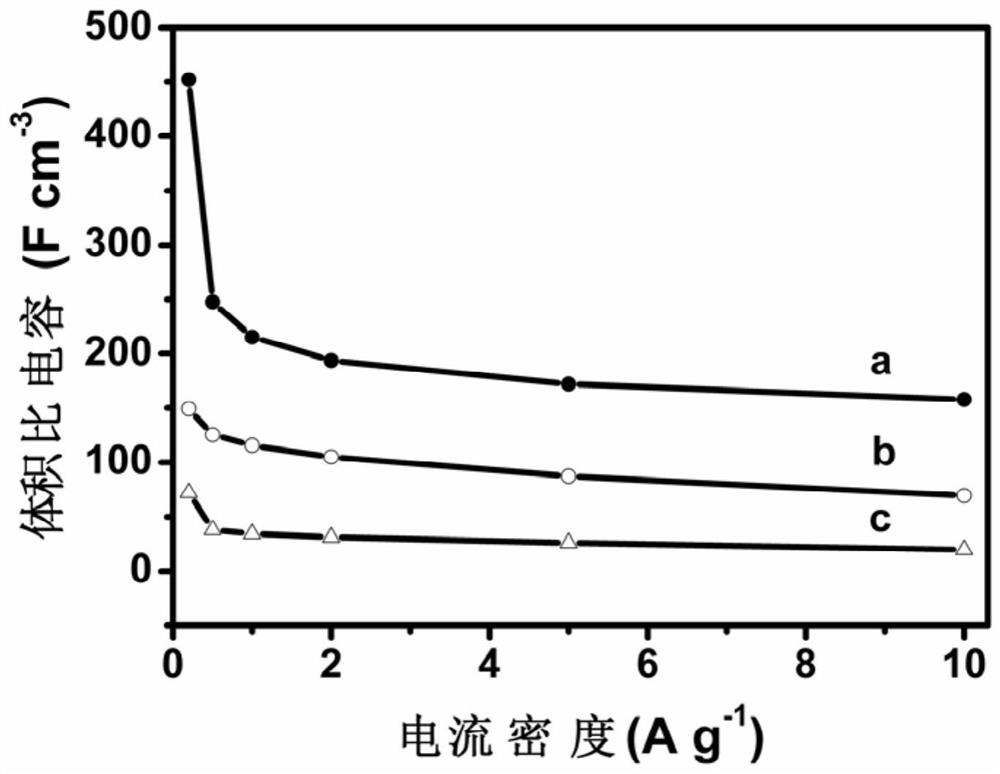

A water-in-oil emulsion and graphite synthesis technology, applied in graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of difficult control of product size and morphology, easy collapse or deformation of spherical structure, etc., and achieve effective ion diffusion. The effect of pathway, large specific surface area, high volume specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

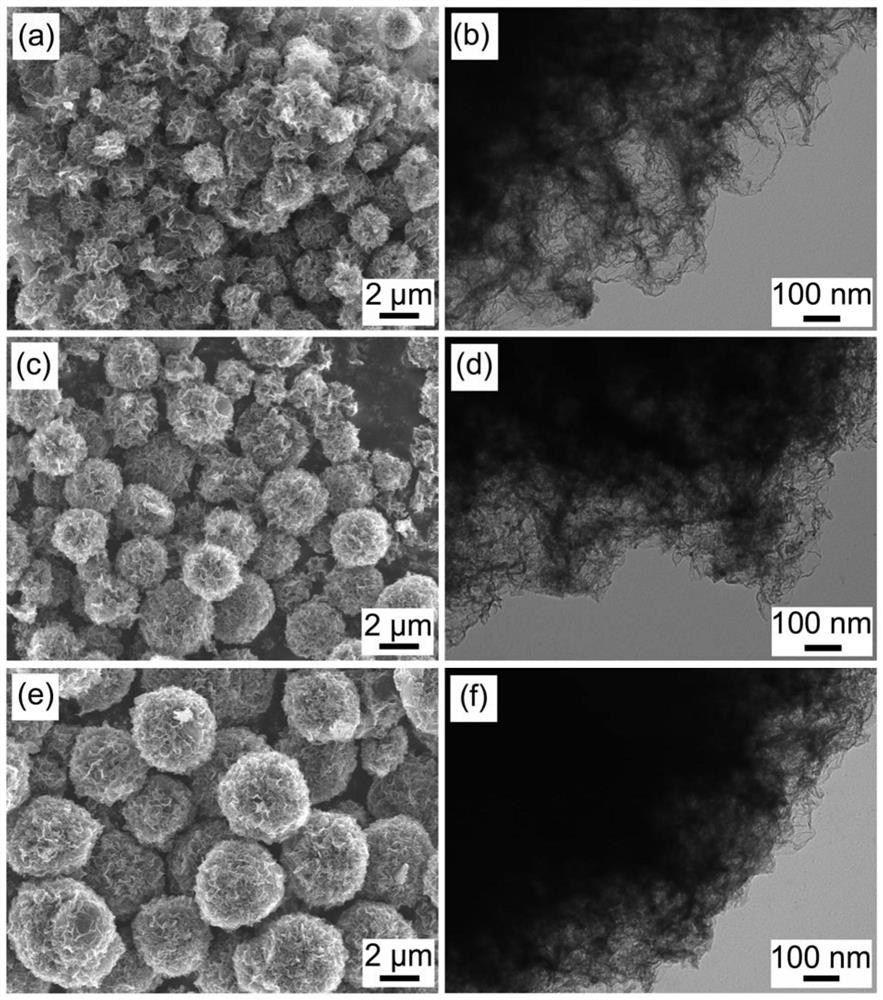

Embodiment 1

[0046] A water-in-oil emulsion method simply controls the method for synthesizing graphene spheres, comprising the following steps:

[0047] (1) Dilute the GO aqueous dispersion to a concentration of 3mg mL -1 The dispersion liquid, standby; PEI is diluted into the solution that concentration is 1wt.%, standby;

[0048] (2) Take 5 mL of PEI solution and add it to 500 mL of oil phase (corn germ oil) for magnetic stirring, raise the reaction temperature to 95°C, stop heating after 3 hours of reaction, cool to room temperature, and obtain the oil phase containing PEI;

[0049] (3) Add 0.15mL EDA to 25mL GO dispersion, sonicate for 30min to obtain the aqueous phase containing GO / EDA complex;

[0050] (4) Add the water phase to the oil phase dropwise, stir vigorously at room temperature to fully emulsify it, and obtain a uniform W / O emulsion;

[0051] (5) heating the emulsion, the heating temperature is 95°C, and the heating time is 4h;

[0052] (6) Cool the reaction system to roo...

Embodiment 2

[0055] A water-in-oil emulsion method simply controls the method for synthesizing graphene spheres, comprising the following steps:

[0056] (1) Dilute the GO aqueous dispersion to a concentration of 3mg mL -1 The dispersion liquid, standby; PEI is diluted into the solution that concentration is 1wt.%, standby;

[0057] (2) Add 0.4 mL of PEI solution to 20 mL of oil phase (corn germ oil) for magnetic stirring, raise the reaction temperature to 95°C, stop heating after 2 hours of reaction, cool to room temperature, and obtain the oil phase containing PEI;

[0058] (3) Add 0.012mL EDA to 2mL GO dispersion, sonicate for 10min to obtain the aqueous phase containing GO / EDA complex;

[0059] (4) Add the water phase to the oil phase dropwise, stir vigorously at room temperature to fully emulsify it, and obtain a uniform W / O emulsion;

[0060] (5) heating the emulsion, the heating temperature is 95°C, and the heating time is 2h;

[0061] (6) Cool the reaction system to room tempera...

Embodiment 3

[0064] A water-in-oil emulsion method simply controls the method for synthesizing graphene spheres, comprising the following steps:

[0065] (1) Dilute the GO aqueous dispersion to a concentration of 3mg mL -1 The dispersion liquid, standby; PEI is diluted into the solution that concentration is 1wt.%, standby;

[0066] (2) Add 4 mL of PEI solution to 100 mL of oil phase (corn germ oil) for magnetic stirring, raise the reaction temperature to 95°C, stop heating after 3 hours of reaction, cool to room temperature, and obtain the oil phase containing PEI;

[0067] (3) Add 0.12mL EDA to 20mL GO dispersion, sonicate for 30min to obtain the aqueous phase containing GO / EDA complex;

[0068] (4) Add the water phase to the oil phase dropwise, stir vigorously at room temperature to fully emulsify it, and obtain a uniform W / O emulsion;

[0069] (5) heating the emulsion, the heating temperature is 95°C, and the heating time is 4h;

[0070] (6) Cool the reaction system to room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com