Automobile maintenance lifting machine directly driven by frameless combined permanent magnet synchronous linear motor

A permanent magnet synchronous straight line and car maintenance technology, which is applied in the direction of magnetic circuits, lifting frames, lifting devices, etc., can solve problems such as loud noise and complex structure, and achieve the effects of increased service life, high control precision, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

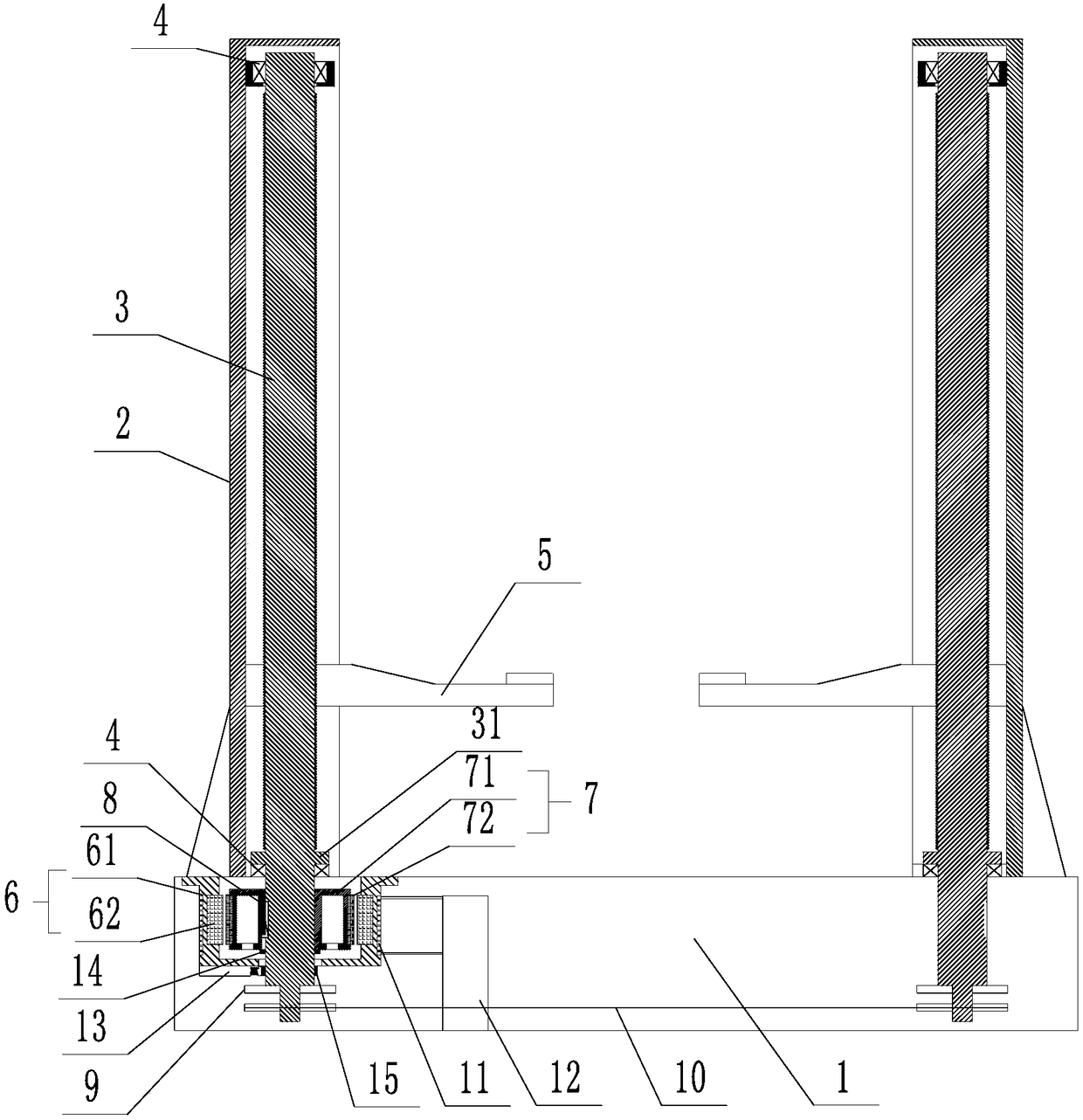

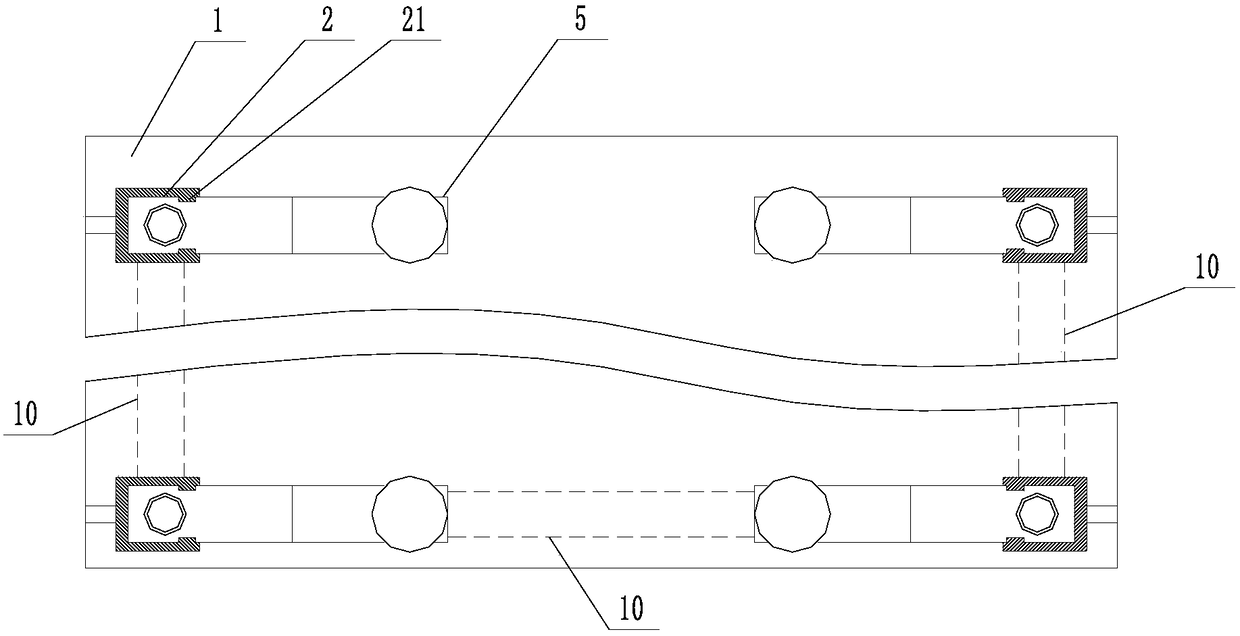

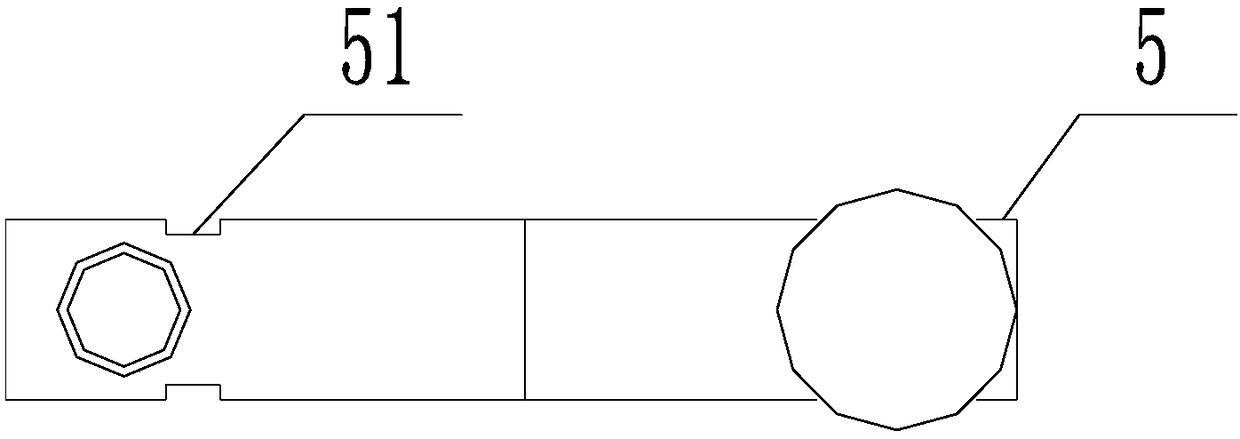

[0032] Such as Figure 1-7 As shown, a frameless combined permanent magnet synchronous linear motor direct-driven car maintenance lift, the lift includes a platform seat 1 and four lifting mechanisms arranged in a rectangular shape on the platform seat, the The lifting mechanism includes a guide column 2, a screw rod 3, and a load-bearing bracket 5; the screw rod 3 provided with a support step 31 is installed in the guide column 2 through a bearing 4; The load-bearing bracket 5 of thread structure is set on the screw rod and moves up and down along the guide column 2; the lower end of the screw rod 3 is provided with a sprocket 9; the sprocket 9 of the four lifting mechanisms passes through The chain 10 is connected, and the screw rod 3 of at least one of the four lifting mechanisms is directly driven by a frameless permanent magnet synchronous motor, and the frameless permanent magnet synchronous motor includes a stator assembly 6 and a rotor assembly 7; The stator assembly ...

Embodiment 2

[0037] Such as Figure 8-10 As described above, a frameless combined permanent magnet synchronous linear motor direct-driven car maintenance lift, the lift includes a platform seat 1 and four lifting mechanisms arranged in a rectangular shape on the platform seat, the The lifting mechanism includes a guide column 2, a screw rod 3, and a load-bearing bracket 5; the screw rod 3 provided with a support step 31 is installed in the guide column 2 through a bearing 4; The load-bearing bracket 5 of thread structure is set on the screw rod and moves up and down along the guide column 2; the lower end of the screw rod 3 is provided with a sprocket 9; the sprocket 9 of the four lifting mechanisms passes through The chain 10 is connected, and the screw rod 3 of at least one of the four lifting mechanisms is directly driven by a frameless permanent magnet synchronous motor, and the frameless permanent magnet synchronous motor includes a stator assembly 6 and a rotor assembly 7; The stato...

Embodiment 3

[0042] Such as Figure 11 As described above, a frameless combined permanent magnet synchronous linear motor direct-driven car maintenance lift, the lift includes a platform seat 1 and four lifting mechanisms arranged in a rectangular shape on the platform seat, the The lifting mechanism includes a guide column 2, a screw rod 3, and a load-bearing bracket 5; the screw rod 3 provided with a support step 31 is installed in the guide column 2 through a bearing 4; The load-bearing bracket 5 of thread structure is set on the screw rod and moves up and down along the guide column 2; the lower end of the screw rod 3 is provided with a sprocket 9; the sprocket 9 of the four lifting mechanisms passes through The chain 10 is connected, and the screw rod 3 of at least one of the four lifting mechanisms is directly driven by a frameless permanent magnet synchronous motor, and the frameless permanent magnet synchronous motor includes a stator assembly 6 and a rotor assembly 7; The stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com