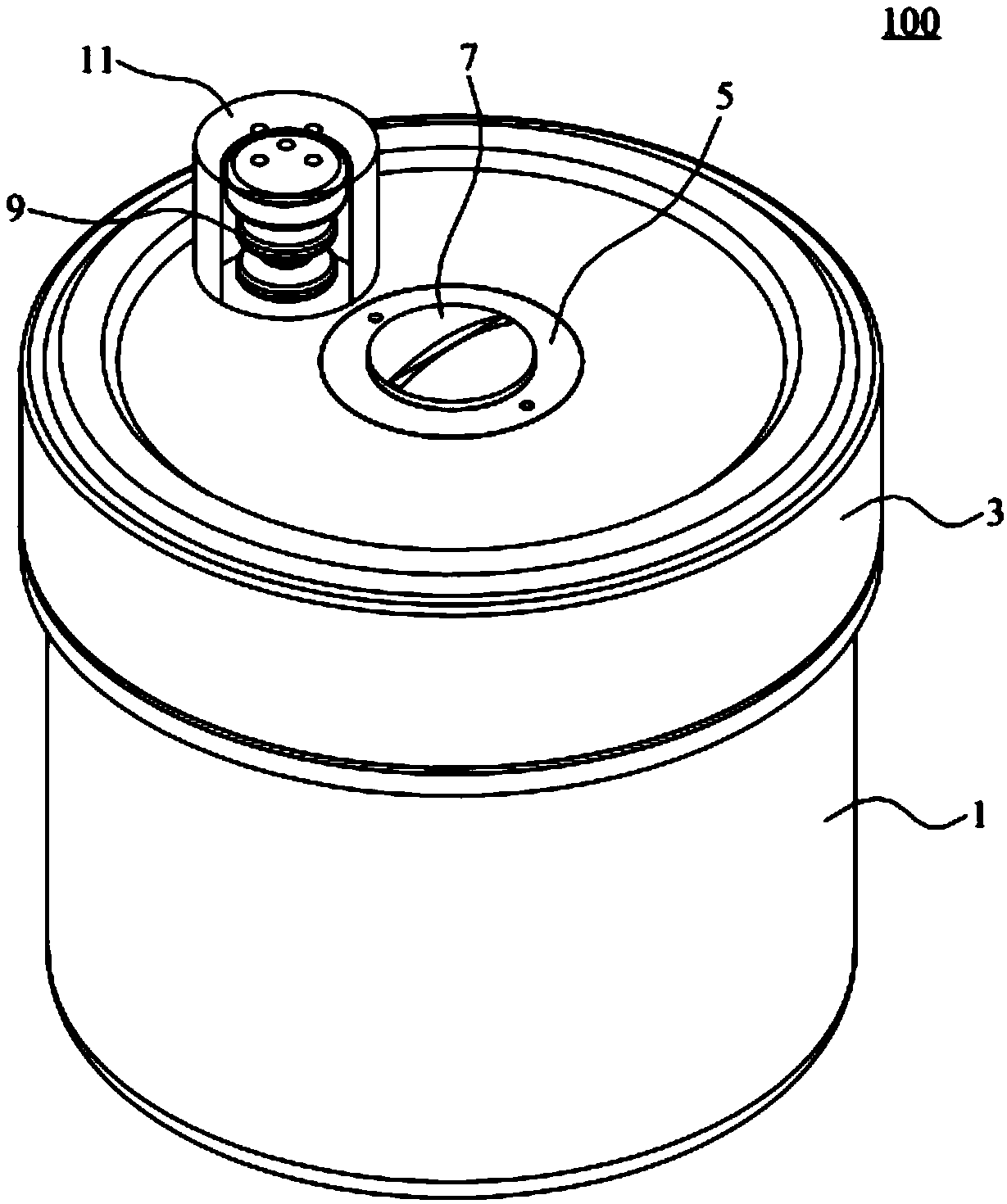

Fluid guiding device and vacuum container having the same

A fluid guiding device and container body technology, applied to packaging under vacuum/special atmosphere, packaging objects under special gas conditions, packaging, etc., can solve the problem of difficulty in maintaining long-term vacuum, complex anti-leakage mechanism, unfavorable transportation, etc. problems, to avoid poor airtightness, convenient transportation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

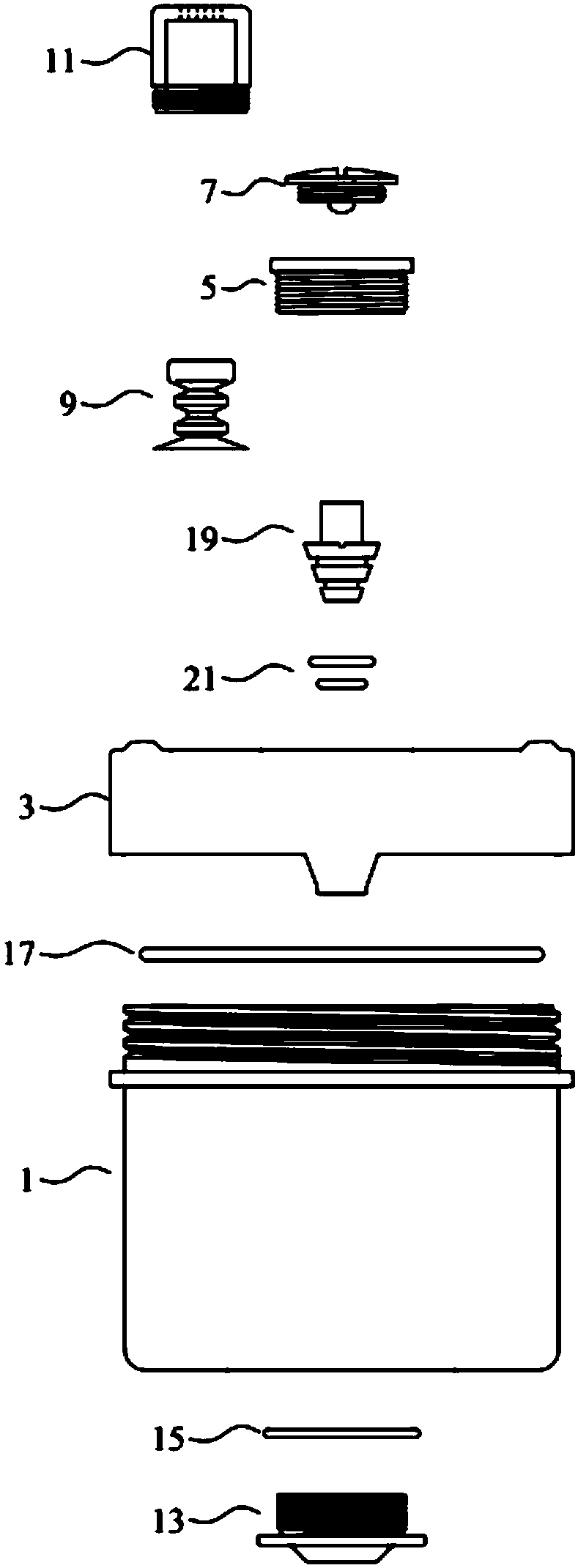

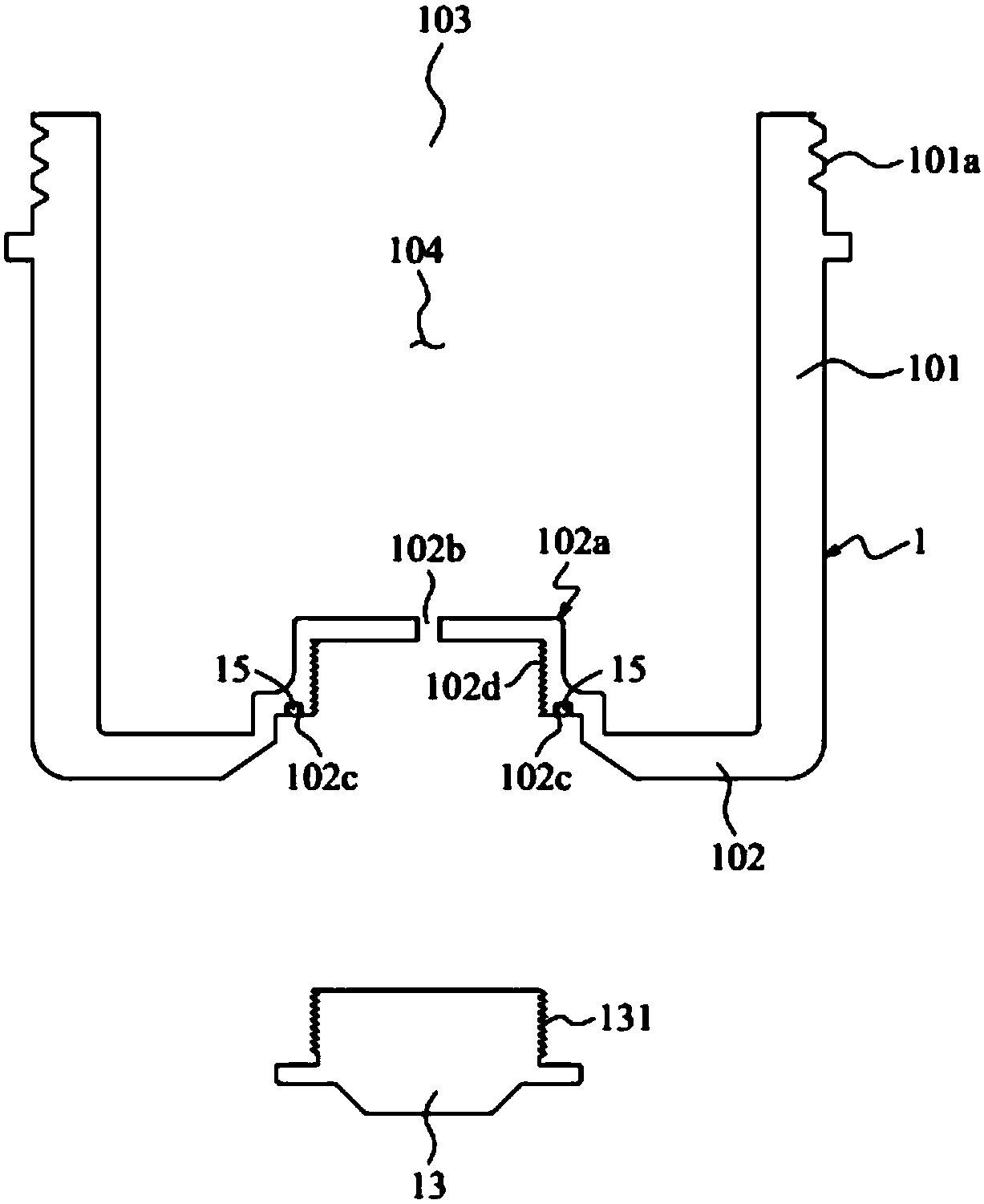

Embodiment 1

[0067] A fluid guiding device such as Figures 7A-7B As shown, it includes a tapered piston 19 and a tapered piston guiding part 5, the tapered piston 19, and the tapered piston 19 can be made of elastic material, such as Figures 5A-5B As shown, the conical piston 19 includes a conical portion 191, and the middle part of the bottom surface of the conical portion 191 is provided with a guiding column 192, and the bottom surface of the conical portion 191 is also provided with a plurality of diversion grooves 191a. In this embodiment, there are four diversion grooves 191a, which are evenly distributed along the bottom surface of the tapered part 191, and the diversion grooves 191a extend from the edge of the bottom surface of the tapered part 191 to the guide post 192, so The tapered portion 191 can be conical or have a pyramidal shape such as a triangular pyramid, a quadrangular pyramid, etc., such as Figures 5A-5B , the tapered portion is a cone;

[0068] The conical pisto...

Embodiment 2

[0076] The difference from Example 1 is that, as Figure 5C As shown, the conical piston 19' can be made of elastic material without the airtight ring receiving groove 191b and the airtight ring 21, and the conical surface of the conical part 191 is provided with the conical part 191. Formed airtight structure 191c.

Embodiment 3

[0078] A fluid guiding device such as Figures 10A-10B As shown, it includes a tapered piston 20 and a tapered piston guide 5', Figure 8A The middle cone piston 20 is Figure 5A A modified example of the tapered piston 19, the tapered piston 20 includes a tapered portion 201, such as Figures 8A-8B As shown, the middle part of the bottom surface of the conical part 201 is provided with a guiding post 202, and the guiding post 202 is a circular cylinder, and the bottom surface of the conical part 201 is also provided with a plurality of first guide grooves 201a , the first guide groove 201a includes four, uniformly distributed along the bottom surface of the tapered part 201, the first guide groove 201a extends from the edge of the bottom surface of the tapered part 201 to the guide A column 202, the alignment column 202 is also provided with a plurality of second flow guiding grooves 202a connected with the first flow guiding groove 201a, and the second flow guiding grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com