High-speed AC five-axis linkage double swing head

A five-axis linkage, double swing head technology, applied in the direction of large fixed members, metal processing mechanical parts, metal processing equipment, etc., can solve the problems of difficult to meet high-precision CNC machining requirements, easy loss of accuracy, large product errors, etc. Achieve the effect of simple structure, improved accuracy and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

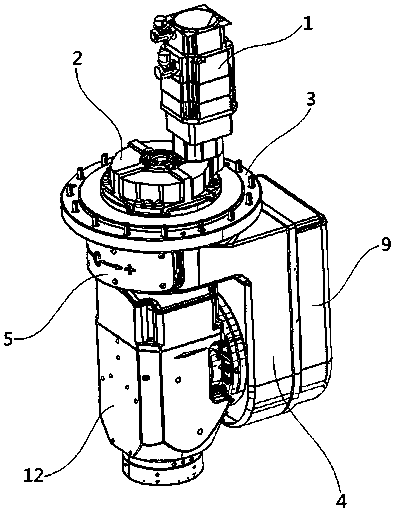

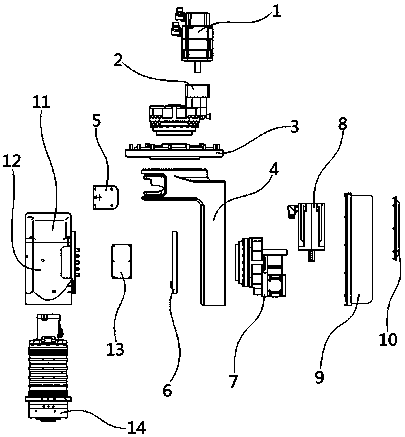

[0074] like Figure 1-2 As shown, a high-speed AC five-axis linkage double swing head includes a C-axis motor 1, an A-axis motor 8, and an electric spindle 14. One end of the output shaft of the C-axis motor 1 is provided with a C-axis reducer 2, and the C-axis reducer 2 A C-axis connection plate 3 is provided on one surface of the C-axis reducer 2, and a main body 4 is provided at the output port of the C-axis reducer 2;

[0075] One side of the main body 4 is provided with a main body left protective cover 5, one surface of the main body 4 is provided with an A-axis right protective cover 9, and one surface of the A-axis right protective cover 9 is provided with an A-axis right motor protective cover 10;

[0076] One end of the output shaft of the A-axis motor 8 is provided with an A-axis reducer 7, and one surface of the A-axis reducer 7 is fixedly connected to the main body 4;

[0077] The surface of the electric spindle 14 is covered with an electric spindle connecting s...

specific Embodiment 2

[0084] The invention itself has multiple adjustable nuts to compensate for the size deviation caused by processing and form a deviation adjustment function in the installation process. The adjustment nut technology is described as follows:

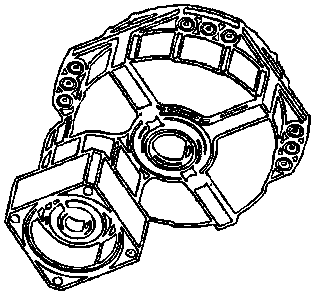

[0085] 1. There are three points 303 on the connecting plate 3 of the C-axis. It can adjust the flatness of the product docking with the CNC machine tool.

[0086] 2. The main body 404 has four anti-tooth nuts, which can adjust the center of the electric spindle to be consistent with the rotation center of the C-axis, and be perpendicular to the installation end surface of the C-axis connection plate 3, thereby realizing the free rotation of the C-axis and the machine tool table The plane is consistent and the A axis is perpendicular to the plane of the machine tool when rotating.

[0087] 3. The two left and right adjusting nuts on the connecting sleeve 12 of the electric spindle can adjust the center of the spindle to be consistent wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com