A double-row double-spray cleaning device for high temperature resistant filter bags

A cleaning device and high temperature resistant technology, applied in the cleaning device of high temperature resistant filter bag, high temperature resistant filter bag for cleaning, double row and double jet cleaning device field, can solve the problem that the high temperature resistant filter bag is not suitable, the surface of the filter bag is damaged, problems such as small force, to achieve the effect of good cleaning quality, high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

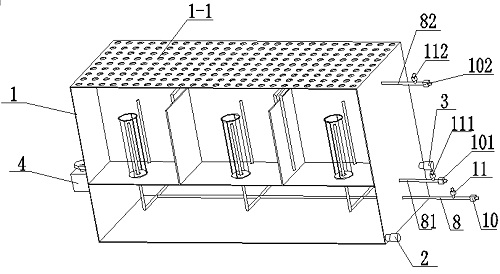

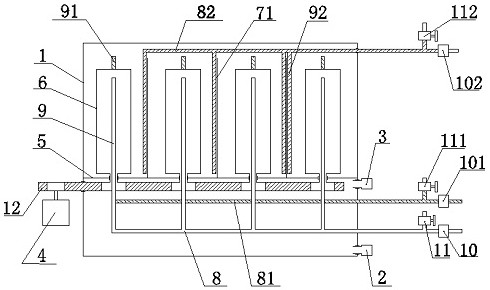

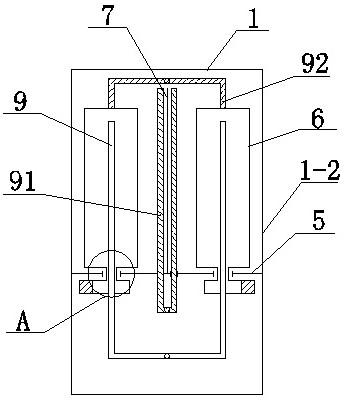

[0042] See Figure 1 ~ 8 A double-row double spray cleaning device for high-temperature filter bag, including a sealed box 1, a power system, a built-in cleaning subsystem, a positive outer bag cleaning subsystem, a lateral outer bag cleaning subsystem, a sewage pump 2, the vacuum pump 3, the interior horizontal horizontal horizontally provided a drain plate 5, the drain plate 5 is located at the lower portion of the casing 1, and the water leak plate 5 is provided with a front and rear two-row filter bag 6 and the lateral cleaning partition 7, longitudinal direction The cleaning partition 71, the lateral cleaning partition 7 is arranged between the two row filter 6, and the plane of the lateral cleaning partition 7 is parallel to the plane of the front side of the casing 1, and the front and rear two-row filter holder 6 is cleaned in lateral cleaning. The plane of the plate 7 is a shaft symmetrical arrangement, and a longitudinal cleaning partition 71 is provided between the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com