A double-row single-spray cleaning device for high-temperature resistant filter bags

A cleaning device and high temperature resistant technology, applied in the field of high temperature resistant filter bag cleaning, double row single spray cleaning device, and high temperature resistant filter bag cleaning device field, can solve the problem of reducing the separation and peeling of dust on the surface of the filter bag and the damage to the surface of the filter bag , small force, etc., to avoid inconsistent cleaning quality, high cleaning efficiency, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

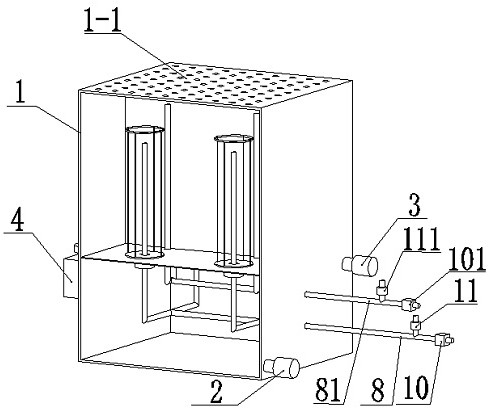

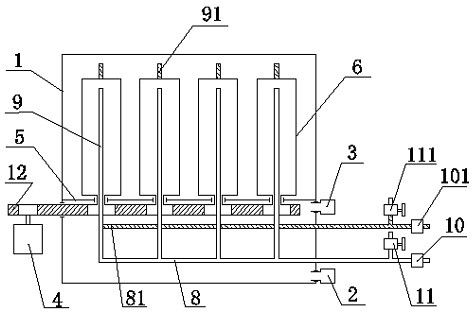

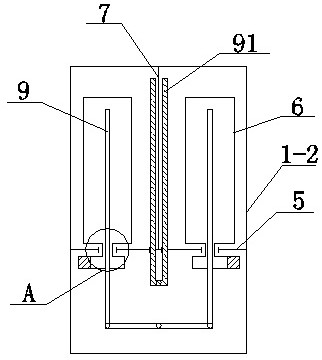

[0040] see Figure 1~Figure 8 , a double-row single-spray cleaning device for high-temperature-resistant filter bags, including a sealed box body 1, a power system, an inner bag cleaning subsystem, an outer bag cleaning subsystem, a sewage pump 2, and a vacuum pump 3. The box body 1 There is a leaking plate 5 installed horizontally inside, and the leaking plate 5 is located at the lower part of the box body 1. Two rows of filter bag holders 6 and cleaning partitions 7 are arranged on the leaking board 5, and the cleaning partitions 7 are arranged on the front and rear rows of filter bag holders Between 6, the plane where the cleaning partition 7 is located is parallel to the plane where the front of the box body 1 is located, and the front and rear rows of filter bag holders 6 are arranged symmetrically with the plane of the cleaning partition 7, and a sewage pump is installed on the side of the box body 1 2. The vacuum pump 3, the sewage pump 2 and the vacuum pump 3 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com