Pulverizing cutting head and pulverizer

A pulverizer and cutter head technology, applied in grain processing, etc., can solve the problems of multi-powder particles, pulverizer congestion, pulverizer damage, etc., and achieve the effects of avoiding concentrated accumulation, uniform stress and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

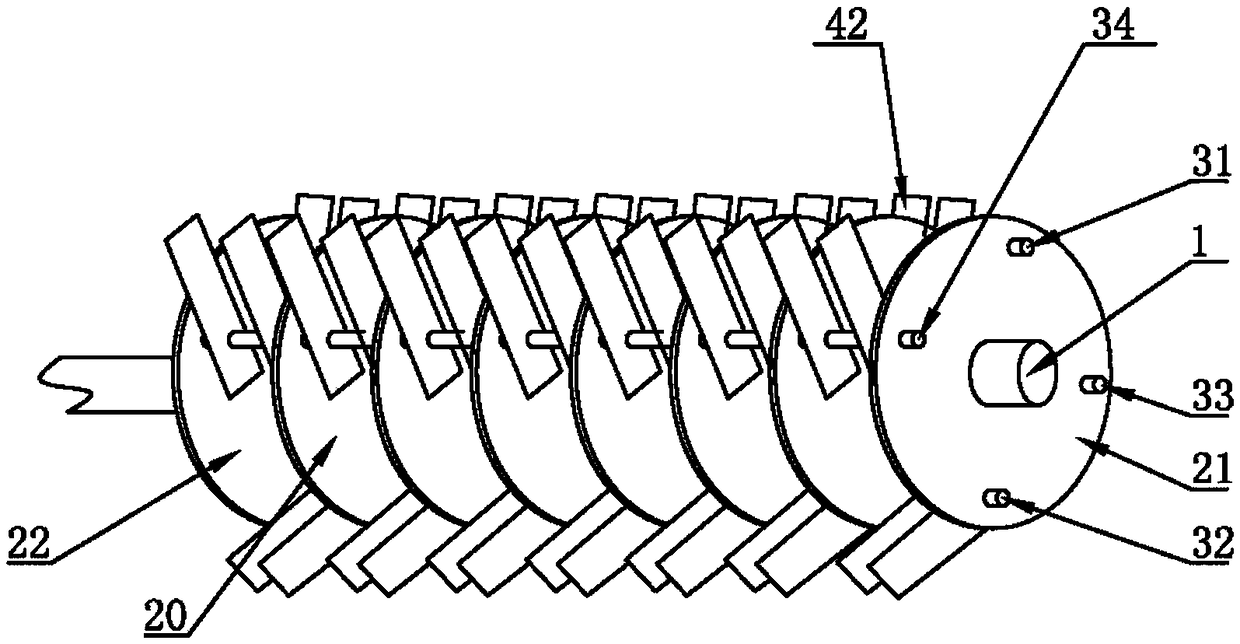

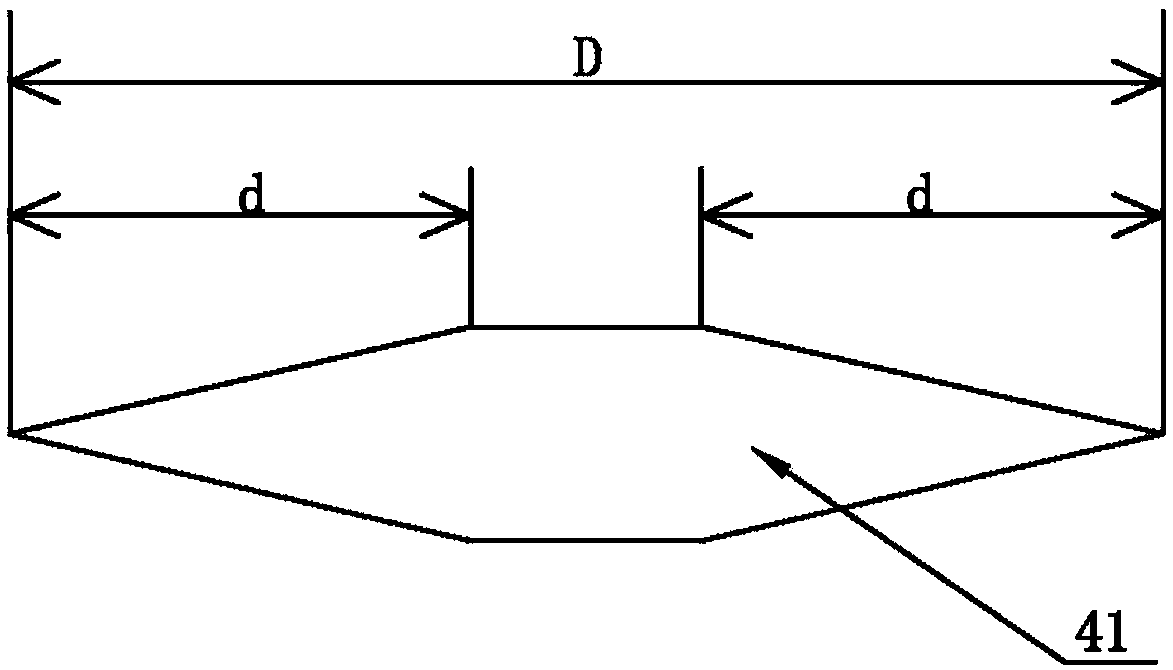

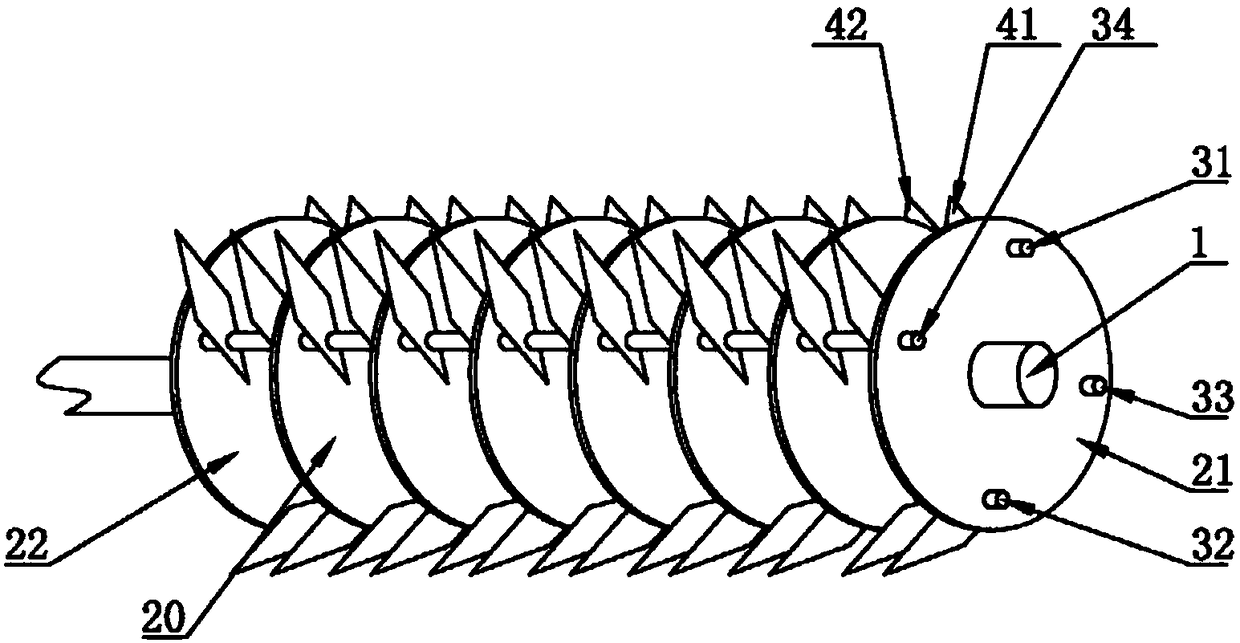

[0051] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and features of a crushing cutter head proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Efficacy, detailed as follows. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

[0052] Example of shredding cutter head

[0053] Such as figure 1 A crushing cutter head shown comprises: a rotating shaft 1; The fixed disks 22 are all perpendicular to the rotating shaft 1 , so that the fixed disks will not encounter too much resistance during the rotation process. N groups of fixing holes are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com