Distribution network maintenance time optimization method and system

An optimization method and distribution network technology, applied in neural learning methods, biological neural network models, instruments, etc., can solve problems such as complicated equipment status evaluation items, large influence of human experience, and difficulty in collecting status quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] The invention provides a method for optimizing the timing of distribution network maintenance based on the equipment health index. The flow chart is as follows Figure 7 shown, including the following steps:

[0121] Collect the relevant data of each feeder equipment in the distribution network to generate the maintenance plan of the distribution network;

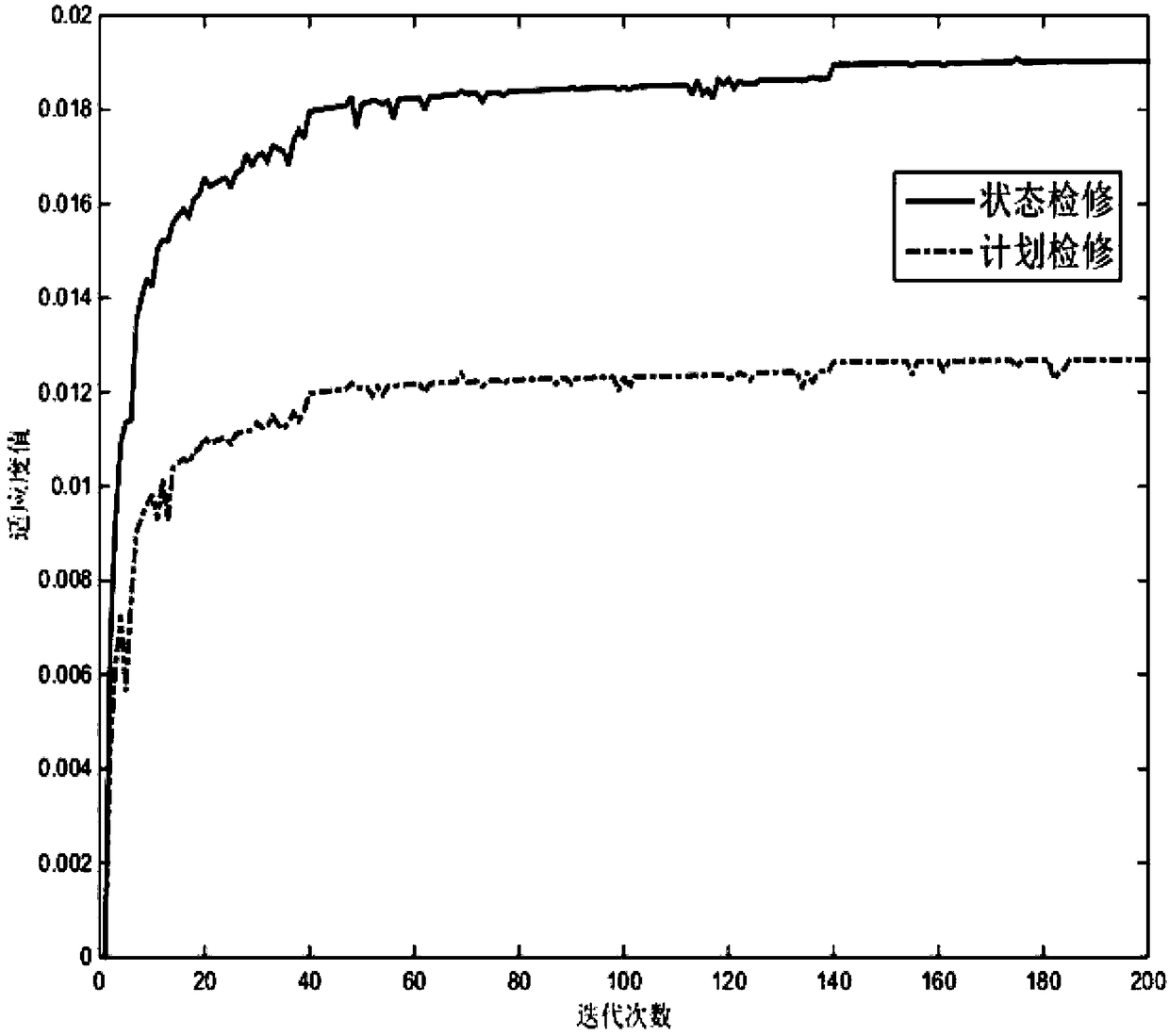

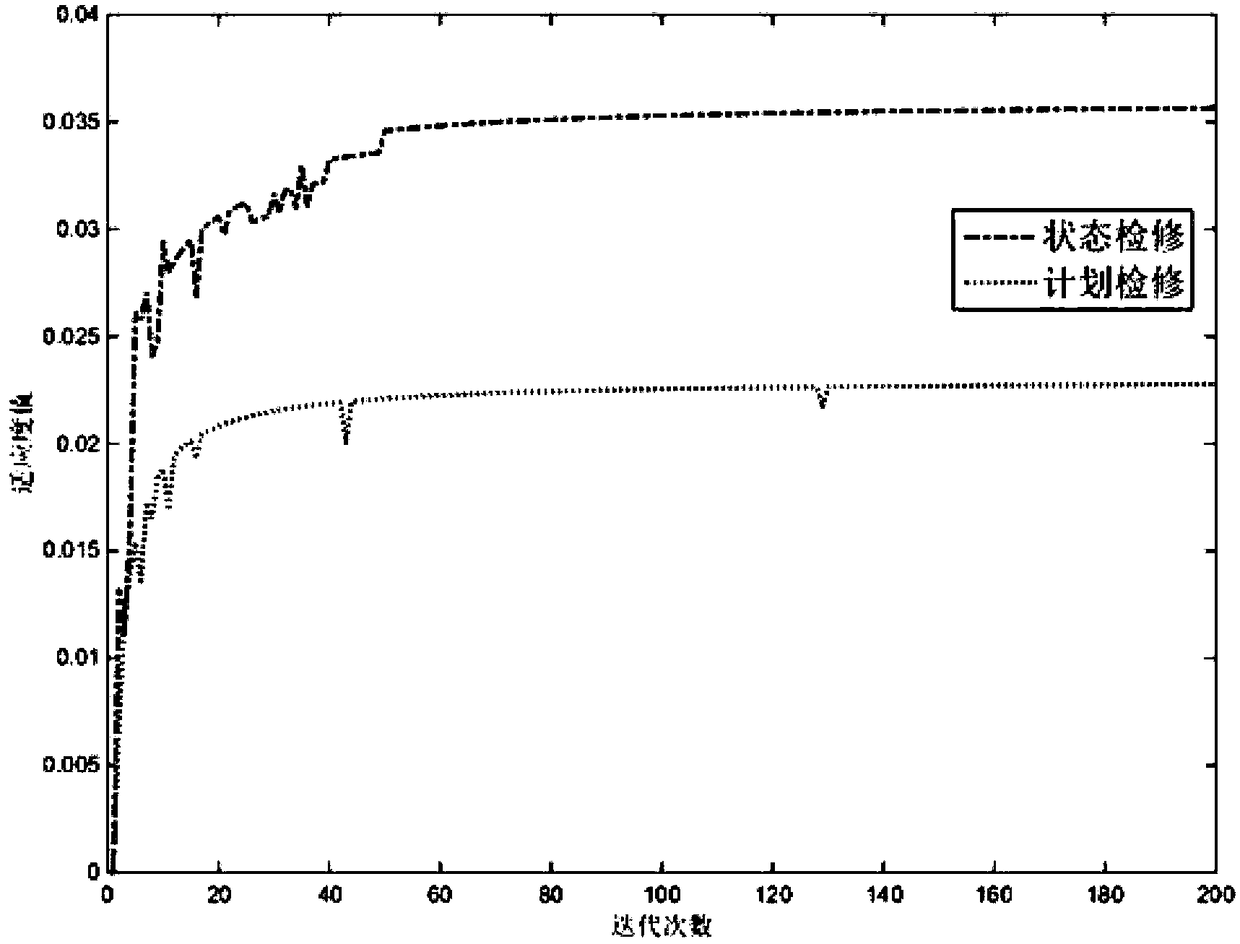

[0122] The distribution network maintenance plan is set as a chromosome, and the genetic algorithm is used to solve the pre-established distribution network state maintenance model to obtain the optimal maintenance time of each feeder;

[0123] The relevant data of each feeder equipment of the distribution network includes: the health index of each feeder equipment of the distribution network.

[0124] The health index includes a scoring interval, and based on the scoring, the equipment on each feeder of the distribution network is classified into grades and maintenance methods are set; the scoring interval is (0,5]...

Embodiment 2

[0234] There are two 10kV substations in the research area to supply power to users, of which the main transformer capacities of station A and station B are 3×40MVA and 2×31.5MVA respectively. The contact relationship between the 10kV distribution network feeders of Station A and Station B is as follows: figure 2 shown.

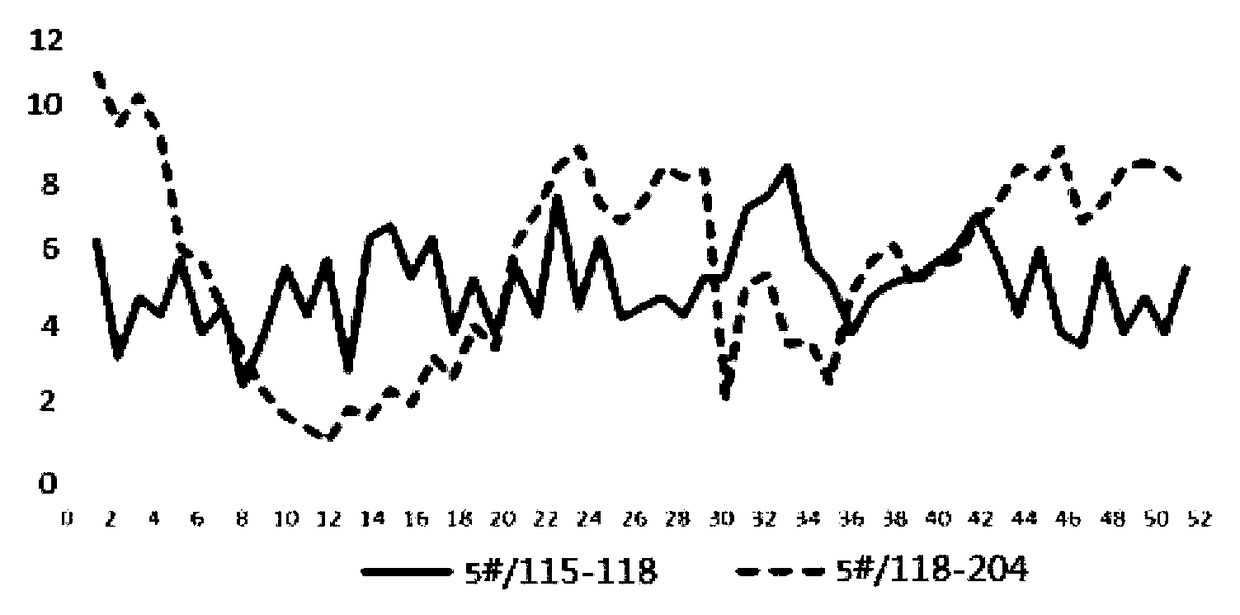

[0235] The research scope selects the 3# distribution feeder of station A and the 5# distribution feeder of station B in the distribution network, of which the 3# feeder is an overhead line and the 5# feeder is a cable line, and the equipment to be inspected is determined according to the health index of each equipment, as shown in the table 5 Bold equipment; the corresponding load forecast curve is as follows image 3 , Figure 4 shown.

[0236] Table 5 Equipment models and health index scores

[0237]

[0238] For the convenience of calculation, the average value of the corresponding interval lengths is taken as the maintenance duration of each main...

Embodiment 3

[0257] Based on the same inventive concept, the present invention also provides a distribution network maintenance timing optimization system based on equipment health index, including:

[0258] The collection module is used to collect relevant data of each feeder equipment in the distribution network to generate a maintenance plan for the distribution network;

[0259] A solution module, configured to set the distribution network maintenance plan as a chromosome, and use a genetic algorithm to solve the pre-established distribution network state maintenance model to obtain the optimal maintenance time of each feeder;

[0260] The relevant data of each feeder equipment of the distribution network includes: the health index of each feeder equipment of the distribution network.

[0261] Further: also include building blocks, said building blocks include:

[0262] The first construction unit is used to establish the distribution network maintenance objective function;

[0263] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com