Method for determining degradation failure thresholds of abrasive particle characteristic parameters of vehicle power transmission device

A characteristic parameter and transmission technology, applied in the field of vehicle power transmission research, can solve problems such as costing a lot of manpower, material resources, and financial resources, not fully considering structural differences in the working environment, and not suitable for real-time state evaluation of power transmission devices, etc., to achieve reasonably estimated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

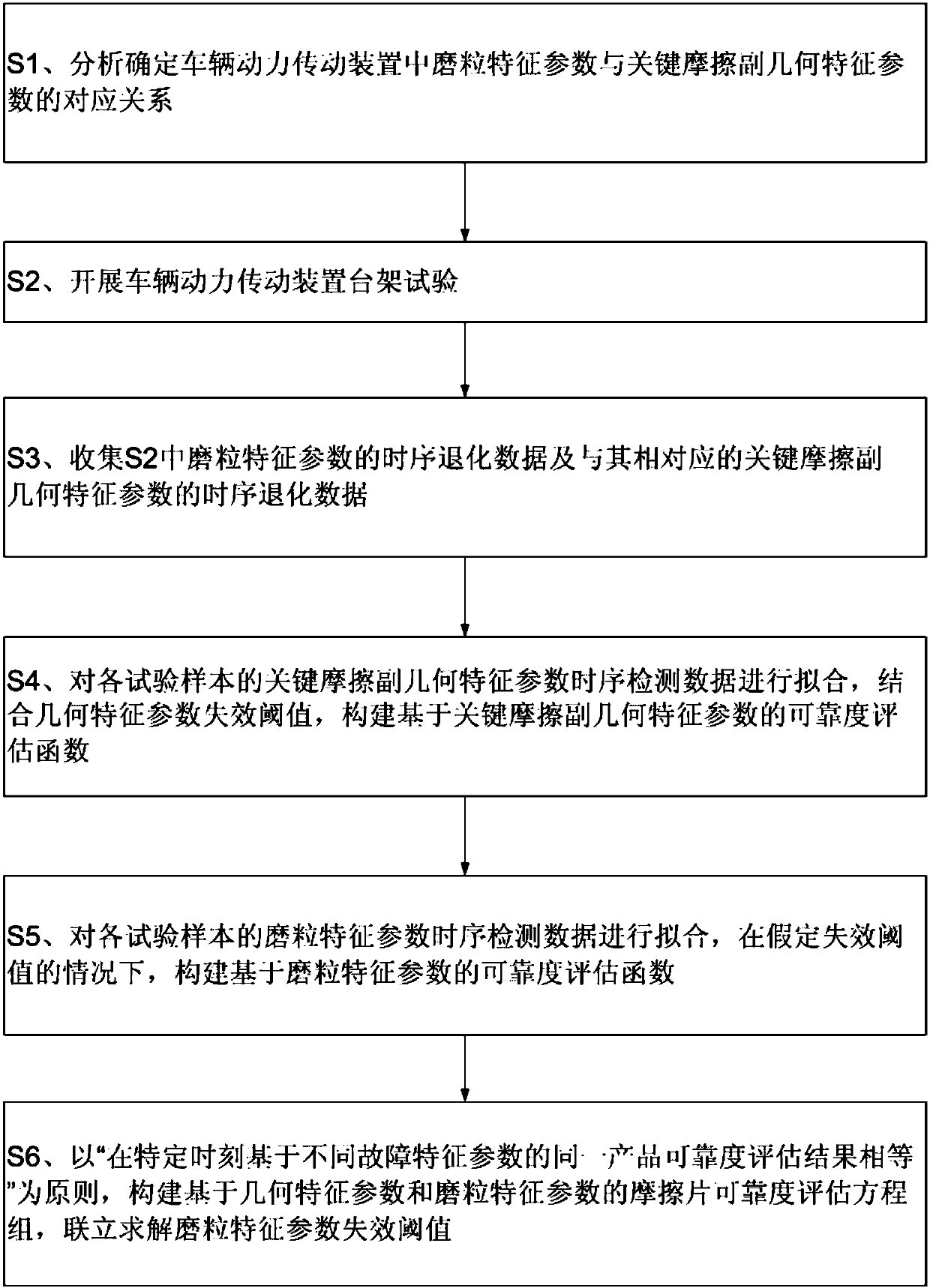

[0049] Such as figure 1 As shown, this embodiment provides a method for determining the failure threshold of wear particle characteristic parameters of a vehicle power transmission device based on the degradation data of geometric characteristic parameters of key friction pairs, the degradation data of wear particle characteristic parameters, and the failure threshold of geometric characteristic parameters, including the following steps :

[0050] S1. Based on information such as material composition, wear mechanism, abrasive particle morphology, etc., analyze and determine the corresponding relationship between the characteristic parameters of abrasive particles in the vehicle power transmission device and the geometric characteristic parameters of key friction pairs;

[0051] S2. Carry out the bench test of the vehicle power transmission device, the test sample size shall not be less than 4, and the test time shall not be less than half of the design life;

[0052] S3. When...

Embodiment 2

[0071] The solution of the present invention will be further described below by taking a certain type of power transmission device as an example.

[0072] S1. The internal tooth friction plate of a certain type of vehicle power transmission transposition is a key component that limits its reliability. During the operation of the clutch, the internal tooth friction plate and the external tooth friction plate have sliding friction, resulting in a large amount of wear and abrasive particles entering the lubrication In the oil circulation system, through the analysis of the material composition of each moving part in the power transmission device, it is found that only the internal tooth friction plate contains Cu elements, and the analysis of a large number of experimental data shows that the content of Cu element in the abrasive grains has a significant relationship with the wear of the internal tooth friction plate of the power transmission device. Corresponding relationship, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com