Deep sea deformation gap automatic compensation clamper

An automatic compensation and clamp technology, applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, mechanical equipment, etc., can solve the problem of excessive filtering accuracy requirements, the influence of hydraulic pump reliability, and the large influence of gas temperature and other problems, to achieve the effect of strong anti-pollution ability, compact structure, and enhanced resistance to instantaneous external load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

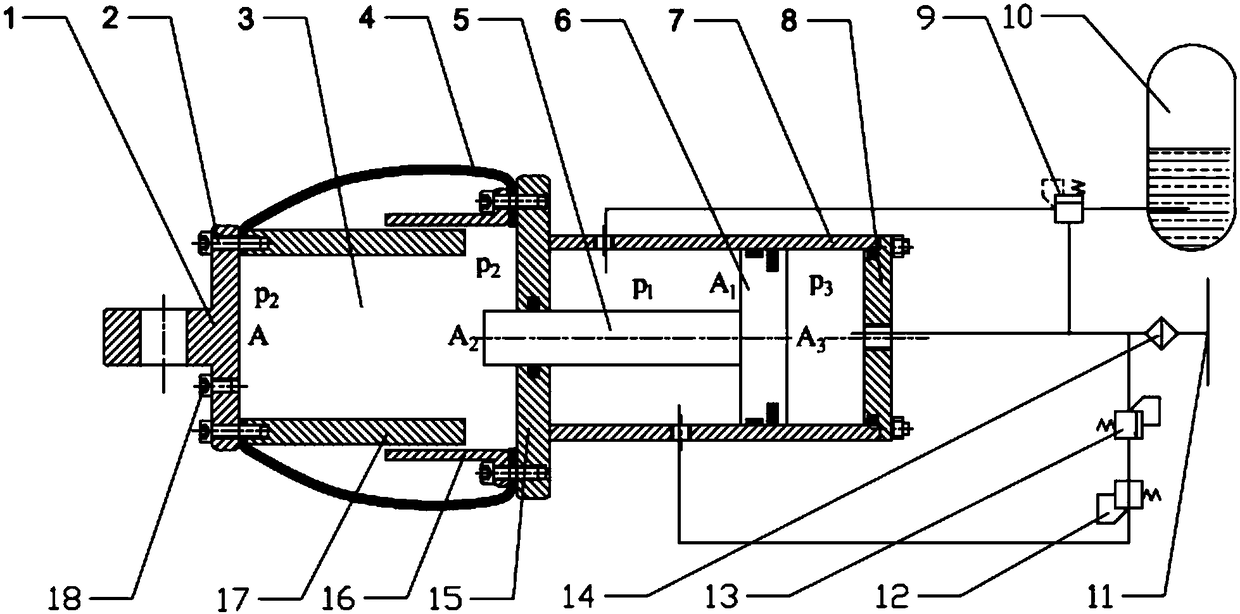

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 with figure 2 As shown, the deep-sea deformation gap automatic compensation clamp of this embodiment includes water bladder rubber 4, and the interior of the water bladder rubber 4 is relatively installed with a support cylinder 17 and a guide cylinder 16, and the end of the support cylinder 17 passes through the lock. Tighten the screw 2 to install the water bag front cover 1, and the end of the guide cylinder 16 is installed with the water bag rear cover 15 by fasteners, thereby forming the water bag cavity 3 inside the support cylinder 17 and the guide cylinder 16; The rear end of the cover 15 is equipped with a water cylinder barrel 7, and the end of the water cylinder barrel 7 is installed with a rear end cover 8 by fasteners. The inside of the water cylinder barrel 7 is equipped with a piston 6, and the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com