Sulfur recovery method and equipment in carbon disulfide production

A carbon disulfide and sulfur recovery technology, applied in the field of sulfur recovery, can solve the problems of low total sulfur recovery rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

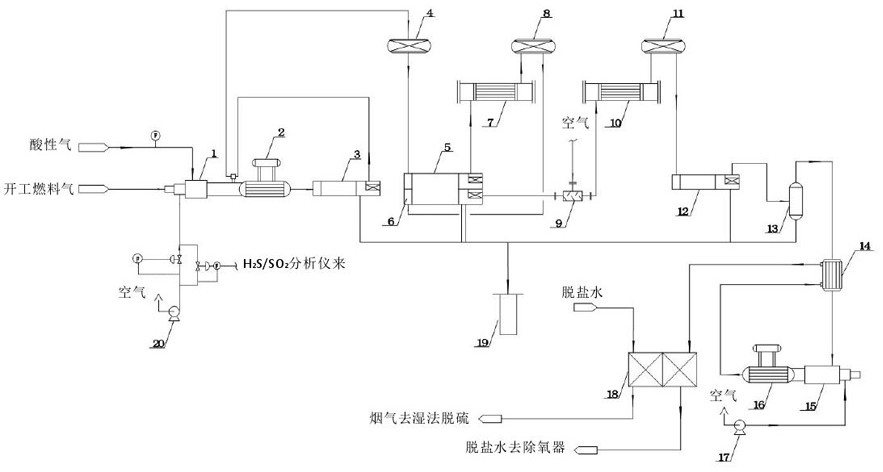

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] Sulfur recovery method in the production of carbon disulfide of the present invention, from the carbon disulfide refining unit containing hydrogen sulfide acid gas (H 2 S content of about 95v%) enters the main burner of the combustion furnace, mixes with a certain proportion of air sent by the combustion furnace blower 20, and burns under oxygen in the combustion furnace 1. ℃, the reaction in the combustion furnace is mainly as follows:

[0029] h 2 S+3 / 2O 2 → SO 2 +H 2 o

[0030] h 2 S+1 / 2SO 2 →H 2 O+3 / 4S 2

[0031] The ratio of acid gas and air is controlled by a ratio regulator, and the amount of air distributed into the combustion furnace is roughly adjusted according to the detected amount of acid gas containing hydrogen sulfide, and according to the outlet connected to the secondary reactor 8 or to the secondary reactor The H a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com