Multi-area continuous forming additive manufacturing laser forming equipment

A technology of additive manufacturing and laser forming, which is applied in the direction of additive manufacturing, processing manufacturing, manufacturing tools, etc., which can solve the problems that the equipment cannot work continuously and the process cycle of forming workpieces is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

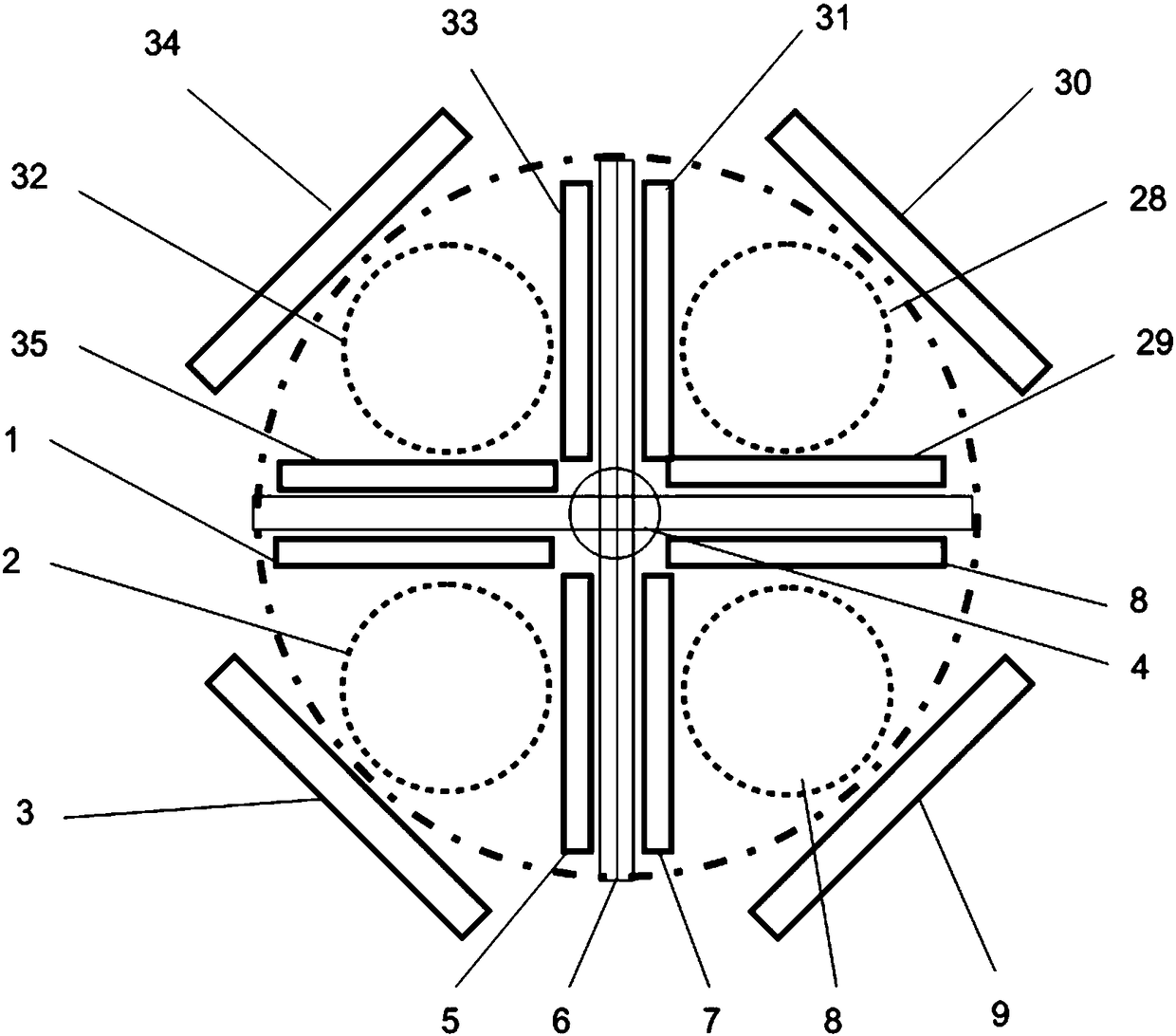

[0030] Such as image 3 As shown, a multi-zone continuous molding additive manufacturing laser molding equipment, taking its four-zone front view as an example, includes a molding chamber 19 and multiple molding shafts corresponding to it, and each molding shaft corresponds to a circular molding area 2, 8, 28, 32, each forming area has its own corresponding laser system (take area a laser system 18 as an example). A rotating shaft 4 is installed in the middle of a plurality of forming areas, and the powder spreading mechanism 6 of a multi-scraper module (taking 11 as an example) is housed on the rotating shaft 4 . When working, the powder spreading mechanism 6 rotates 90° every time to complete the powder spreading requirements of one layer of the four forming areas, and the four forming areas carry out the laser forming process at the same time. When any forming axis is formed, the corresponding forming axis can be replaced independently Warehouse (take the 22-bit forming wa...

Embodiment 2

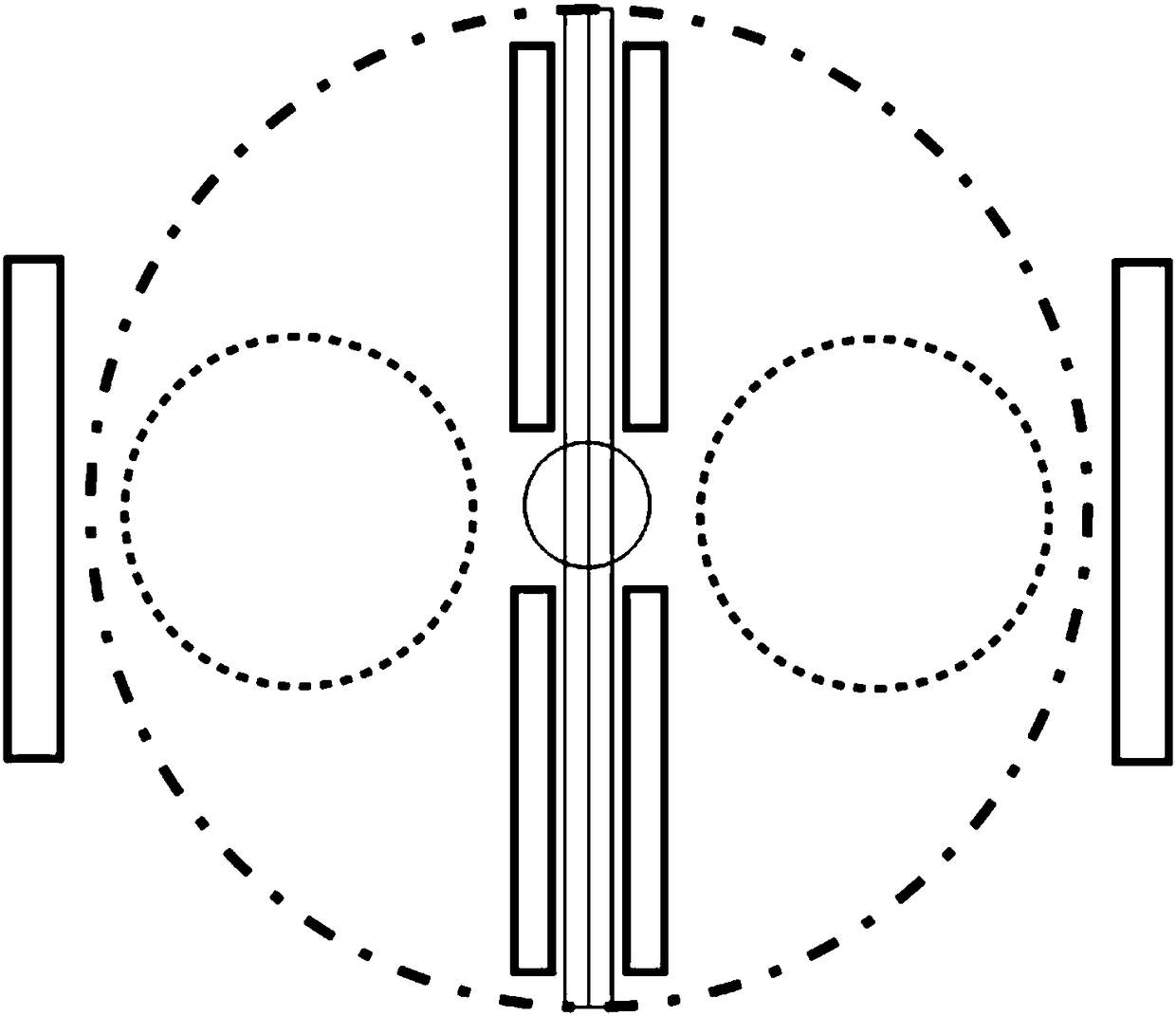

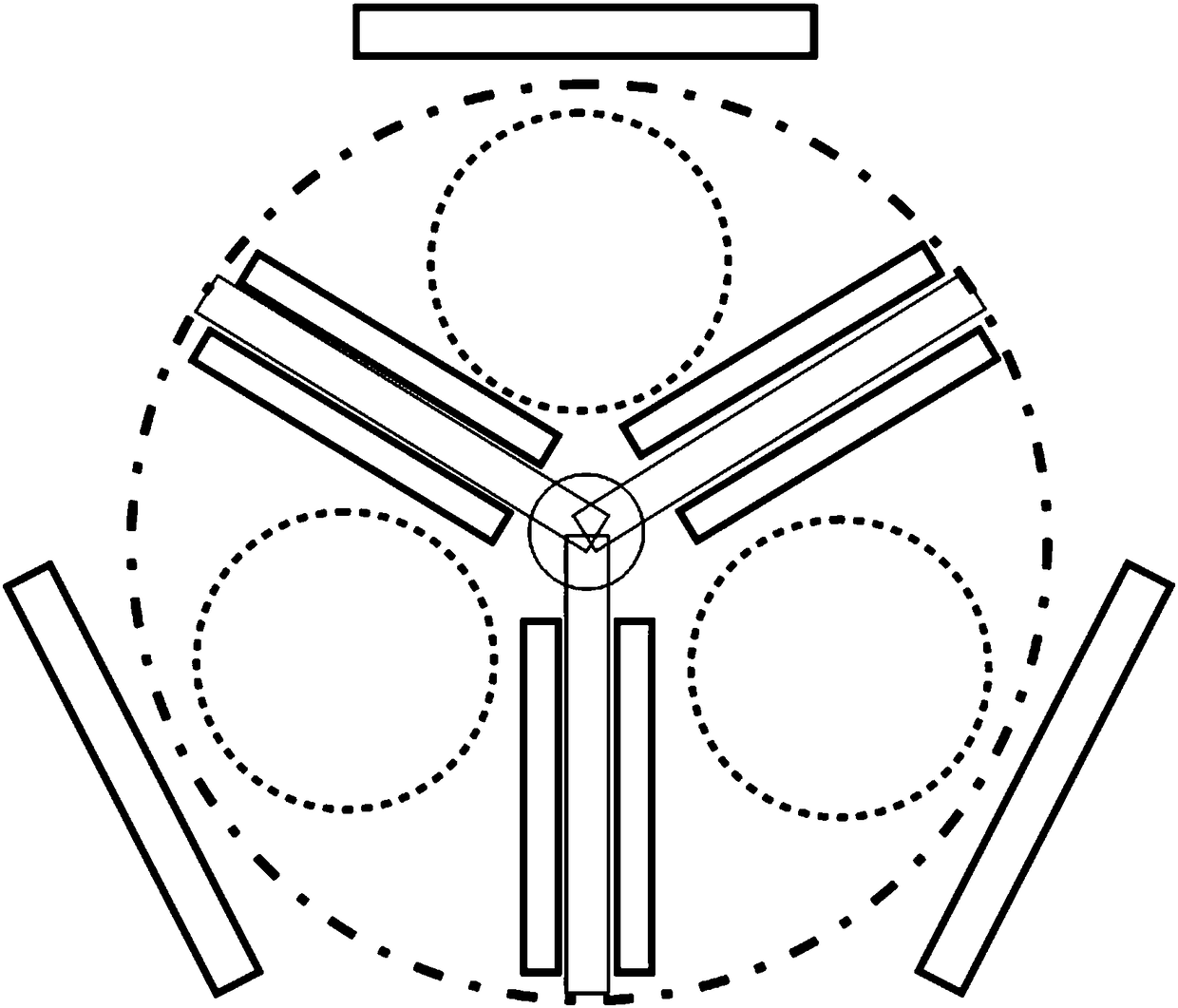

[0050] A kind of multi-area continuous forming additive manufacturing laser forming equipment of the present invention, taking its two-area and three-area forming as an example (such as Figure 1a , 1b ), its function is as follows:

[0051] The overall operation function is as in Example 2. Due to the different forming areas, the corresponding powder spreading devices have different structures. The inner pipeline of the air outlet has two forming areas, powder feeding port, powder collecting port and air inlet, and the powder spreading device completes a laser forming and melting process every time it rotates 180°;

[0052] Further, the three-area powder spreading device is Y-shaped, with three scraper modules, three air outlets, and corresponding inner pipelines of the three air outlets. The forming area, powder feeding port, powder collecting port, and air inlet are all Three, the powder spreading device completes a laser molding and melting process every time it rotates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com