Hardware piece vertical bending process

A hardware and vertical bending technology, applied in the field of hardware vertical bending technology, can solve the problems of waste of resources, excessive bending of pipe fittings, high labor intensity, etc., and achieve the effect of consistent angle, improved bending accuracy, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is a further detailed description through specific implementations:

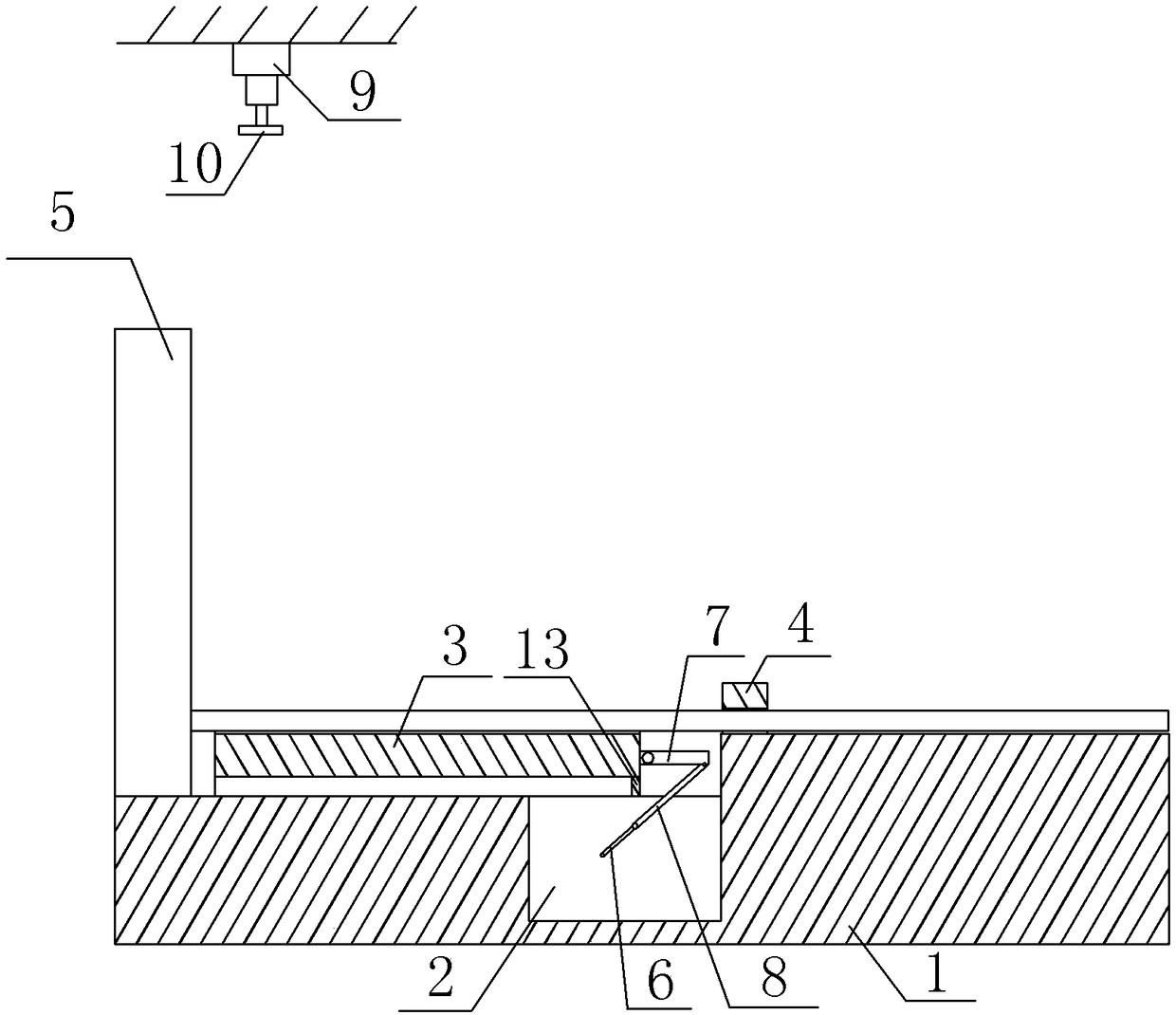

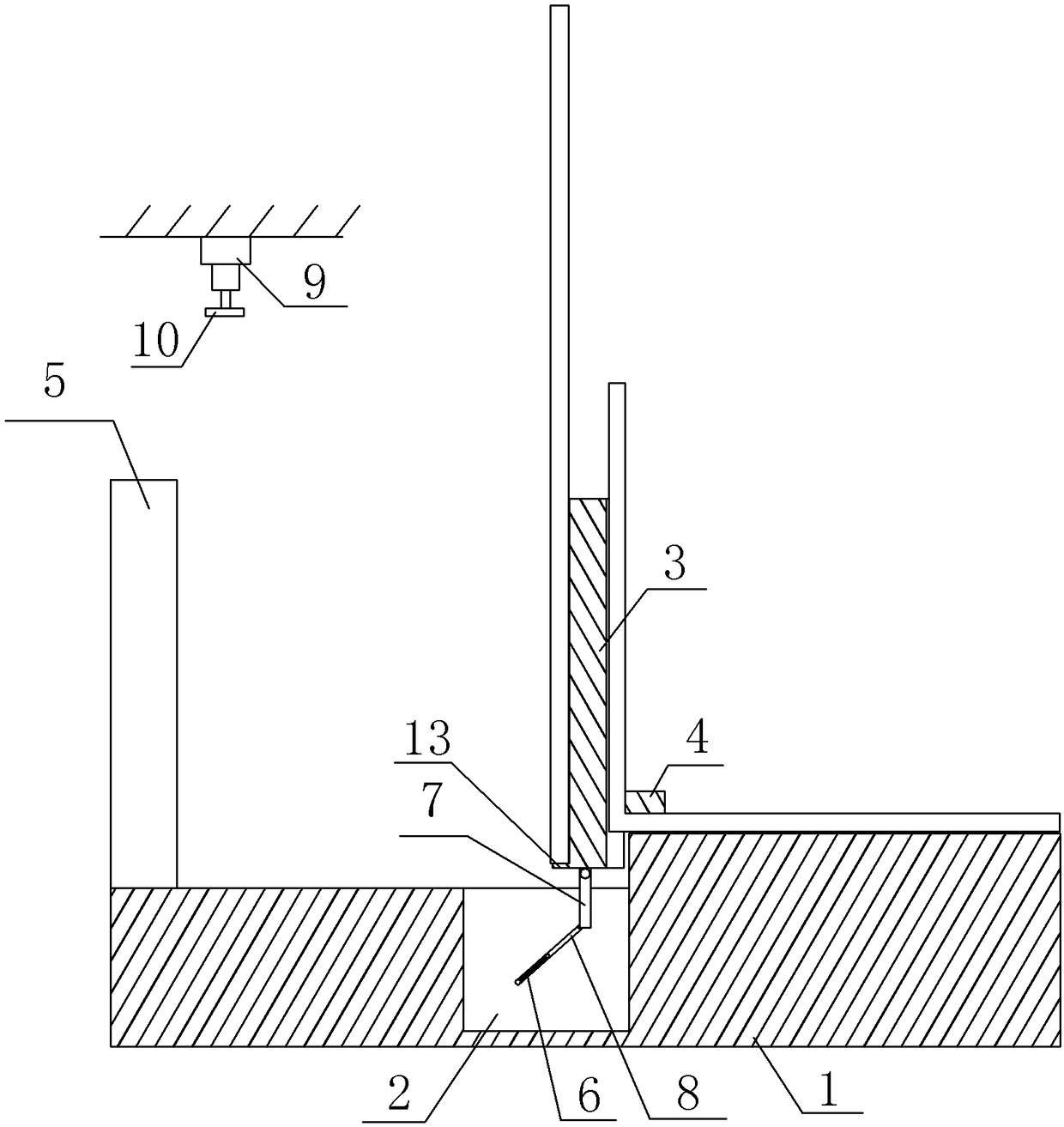

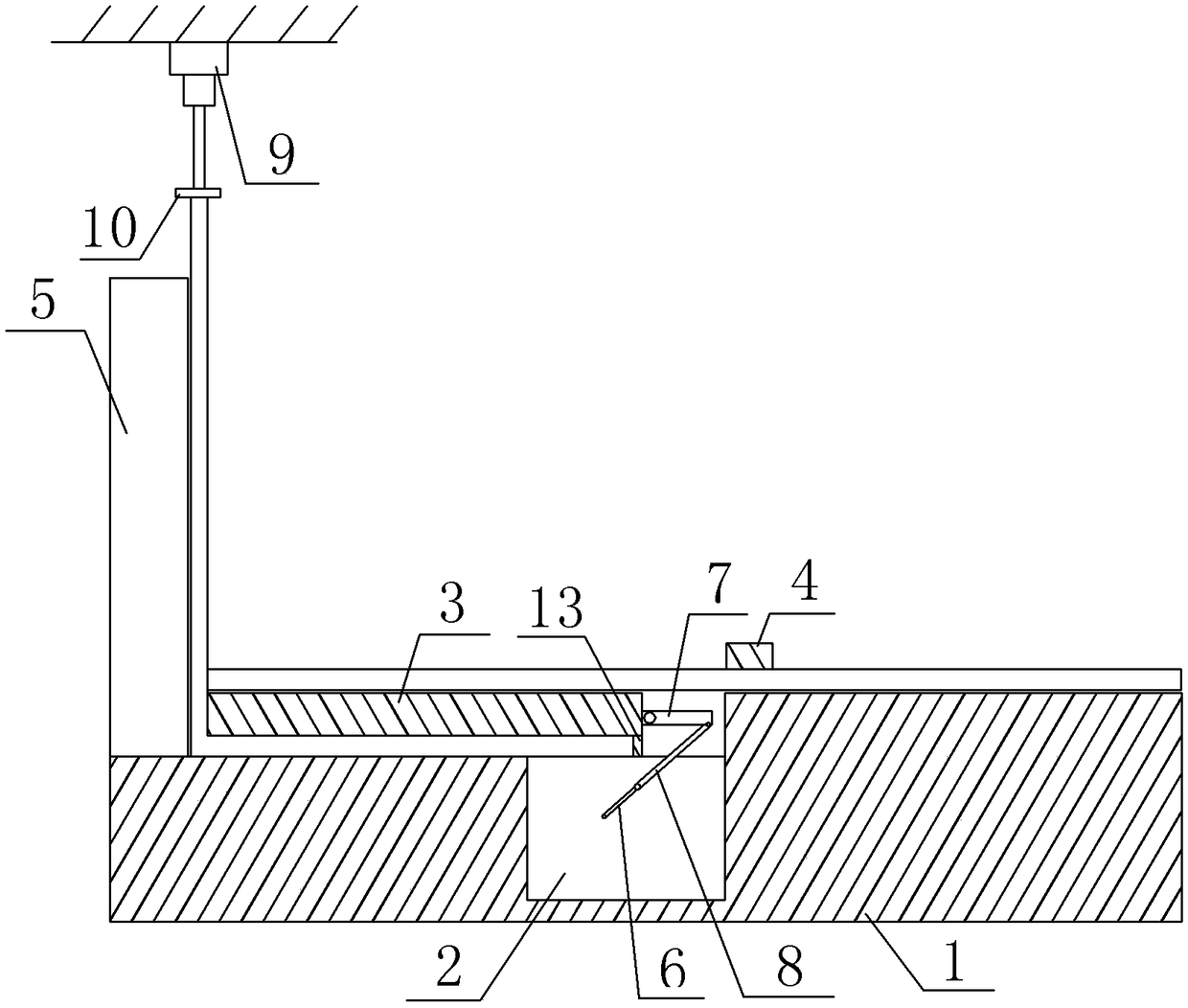

[0025] The reference signs in the drawings of the specification include: support table 1, groove 2, bending strip 3, clamping block 4, bending baffle 5, driving rod 6, driven rod 7, connecting rod 8, cylinder 9, The abutment plate 10, the first arc groove 11, the second arc groove 12, the stopper 13, the strip groove 14, the tension spring 15, and the fastening piece 16.

[0026] A hardware vertical bending process specifically includes the following steps:

[0027] Step 1: Prepare a figure 1 The hardware vertical bending equipment shown includes a supporting table 1 and a bending mechanism. The supporting table 1 is stepped and includes a first table on the left and a second table on the right. A groove 2 is opened on the first table.

[0028] The bending mechanism includes a motor, a crank and rocker unit, a bending strip 3, a clamping block 4 and a bending baffle 5. The motor is located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com