Automatic control of high-precision soft tissue cutting robot

A technology for cutting robots and soft tissue, applied in the field of robotics, can solve problems such as inability to solve tissue cutting, and achieve the effect of reducing cutting difficulties and solving cutting bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

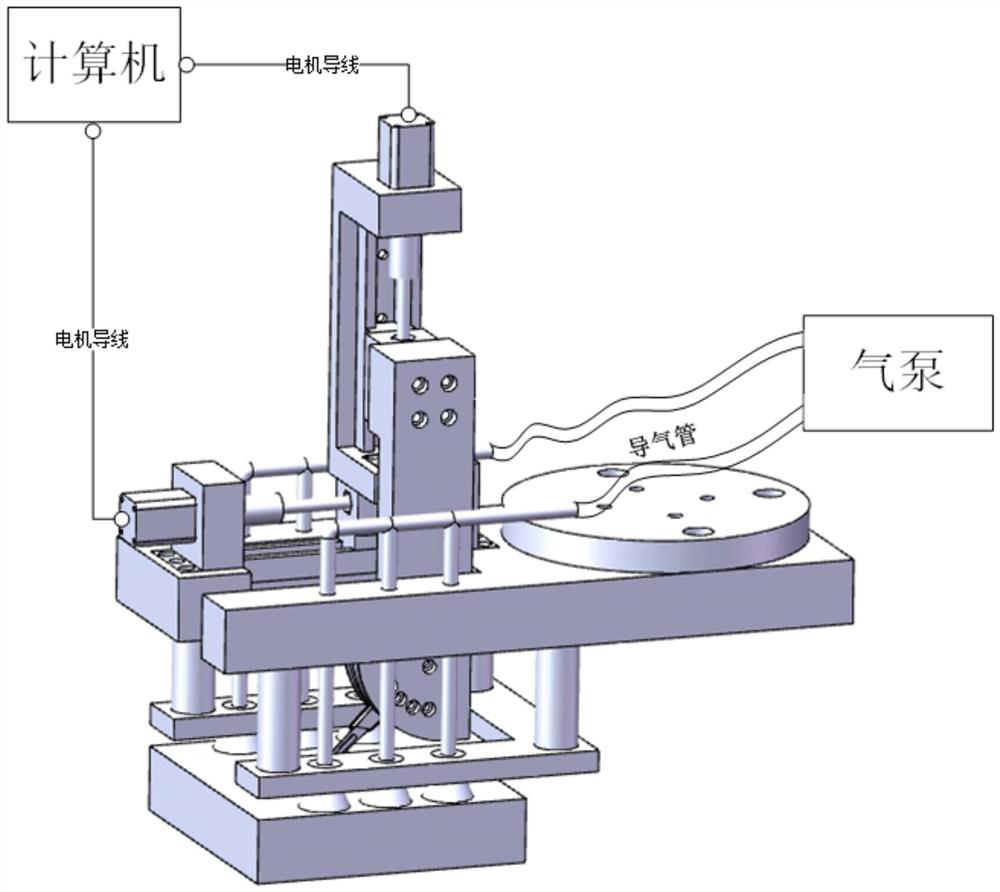

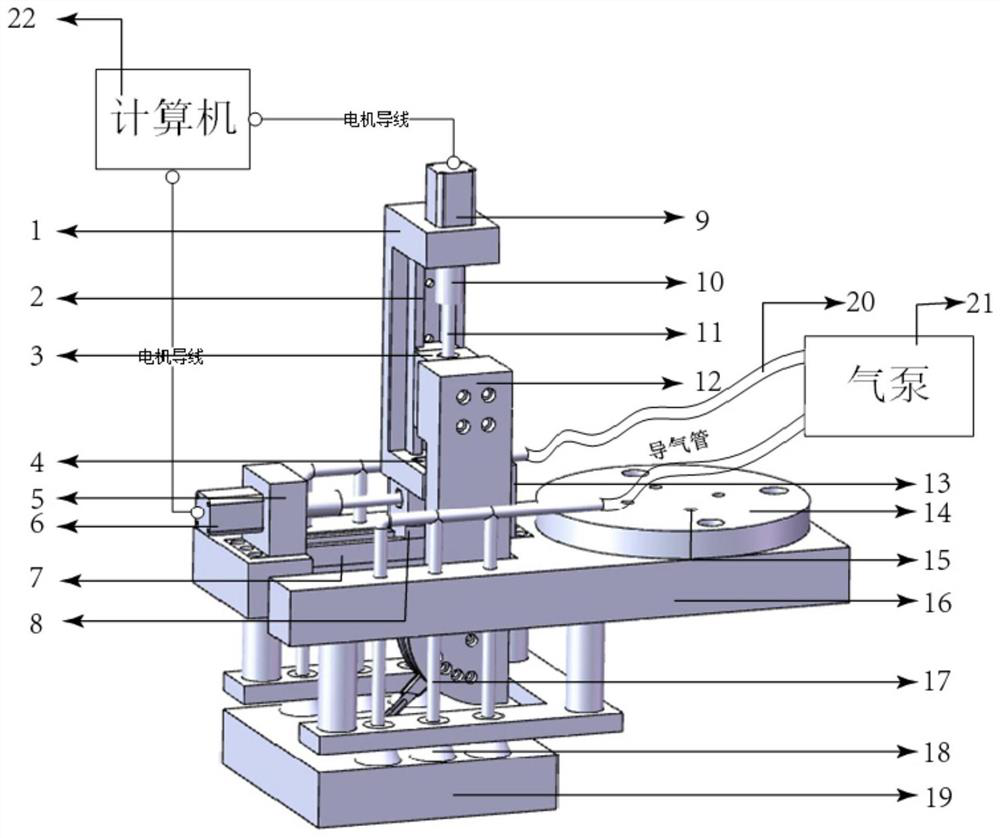

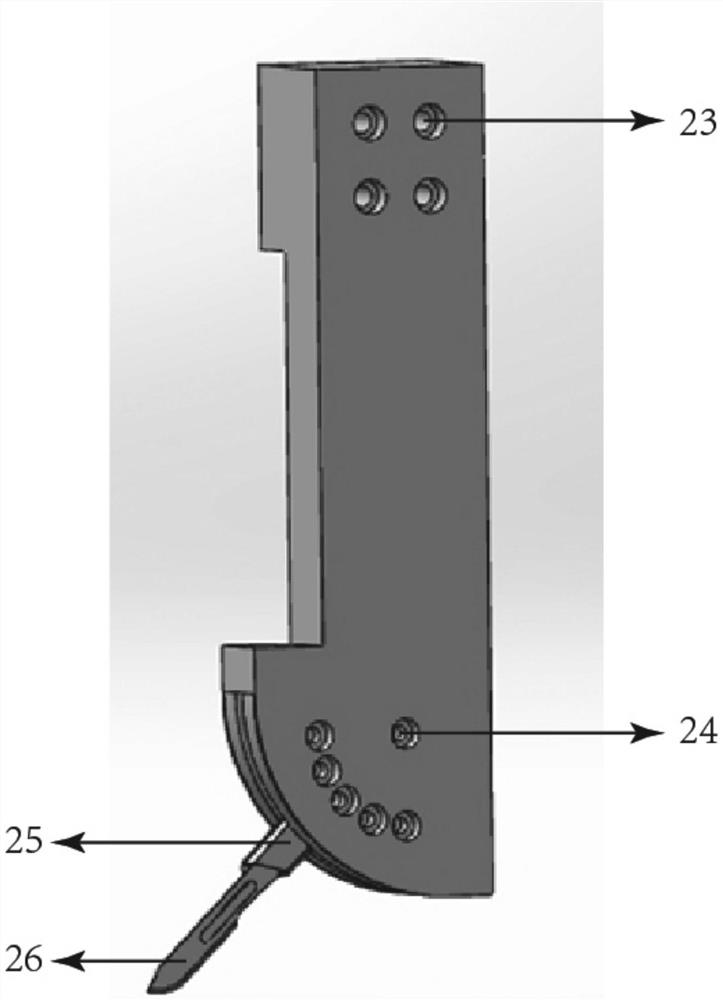

[0019] An automatic control high-precision soft tissue cutting robot, such as figure 2 and image 3 Shown: vertical rail fixing seat 1, vertical rail 2, screw linkage nut 3, horizontal rail stepping motor fixing seat 4, screw bearing 5, horizontal rail stepping motor 6, horizontal rail 7, slider 8, vertical rail Stepping motor 9, coupling 10, screw rod 11, scalpel fixture 12, screw rod bearing holder 13, flange plate 14, mounting hole for flange plate and mechanical arm 15, cutting device chassis 16, air suction duct 17. Vacuum suction cup 18, tissue to be cut 19, air guide tube 20, vacuum air pump 21, computer 22, scalpel fixture and screw mandrel linkage nut mounting hole 23, scalpel mounting hole 24, scalpel handle 25, scalpel blade 26;

[0020] The cutting device consists of a soft tissue fixed support bracket that can be configured with a vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com