Electron beam forming and manufacturing visual monitoring system preventing metal vapor pollution

A monitoring system and metal vapor technology, applied in closed-circuit television systems, components of television systems, televisions, etc., can solve the problems of large volume and limited effect of protective glass, achieve simple structure, low cost, and solve the problem of film replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

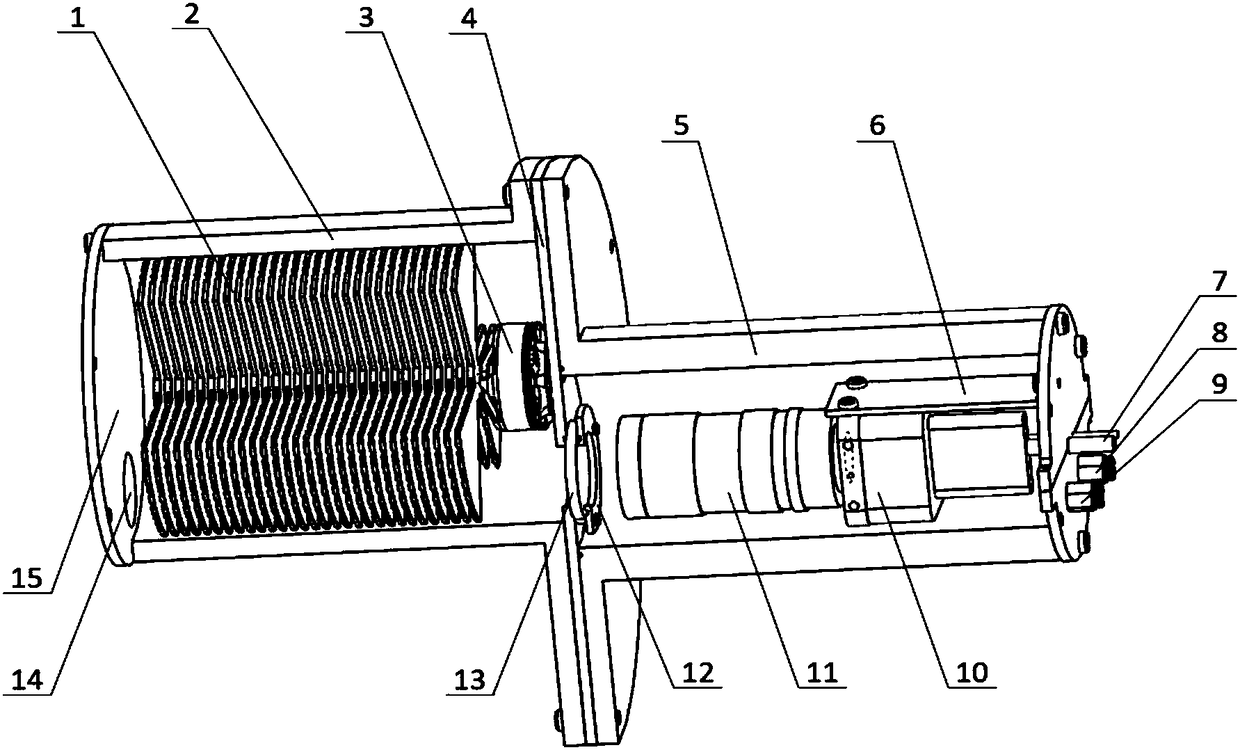

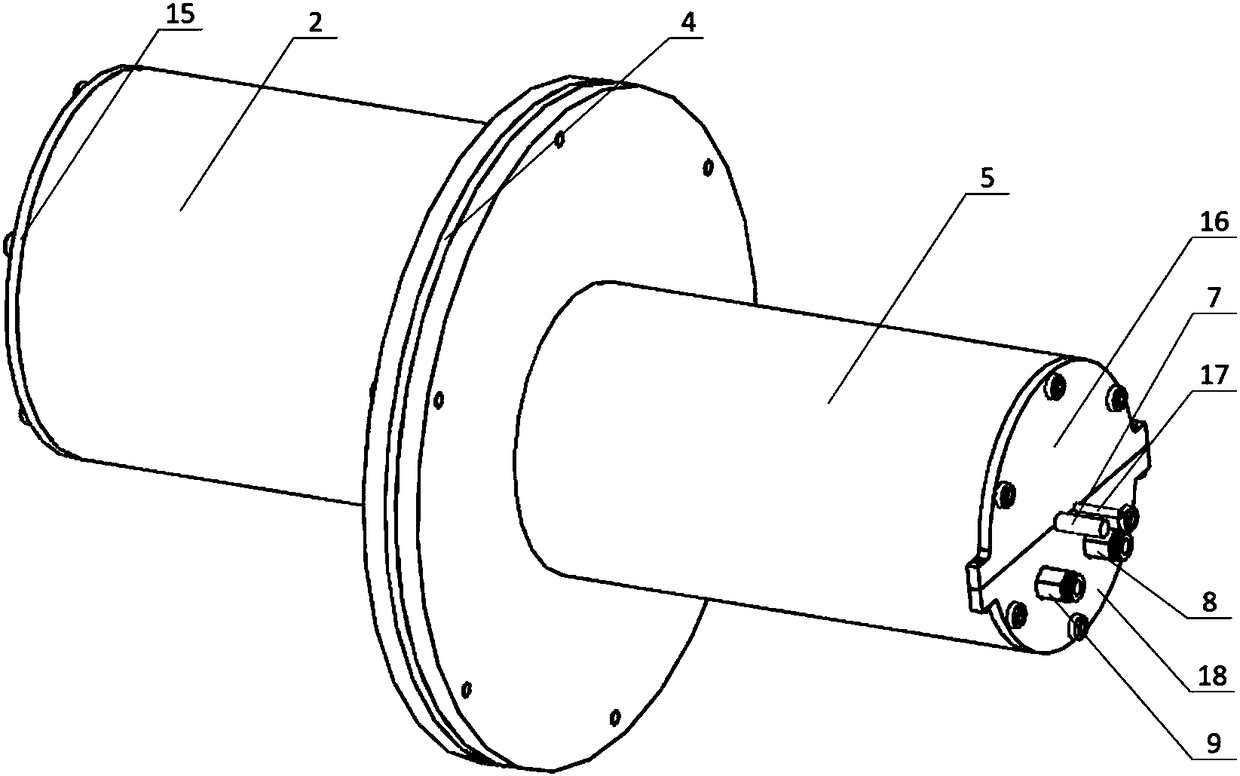

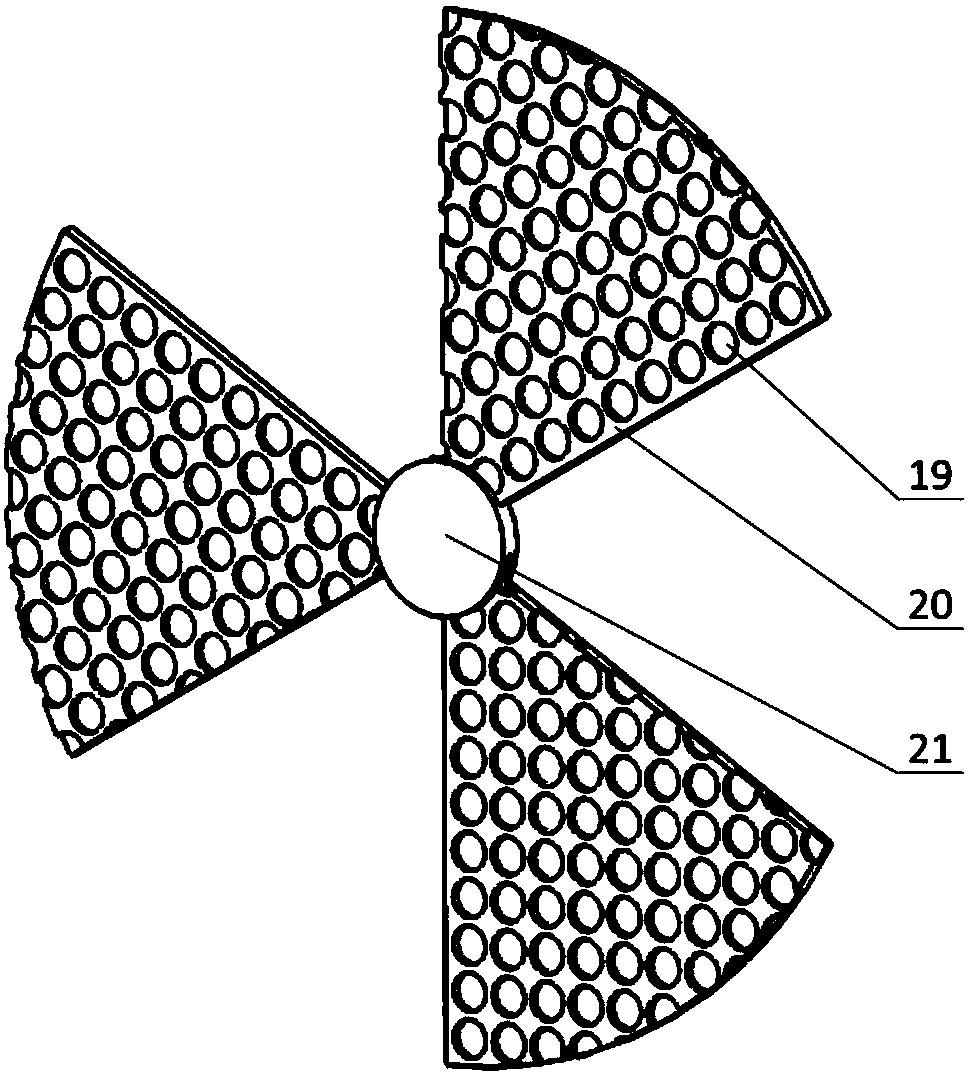

[0020] The electronic beam forming manufacturing visual monitoring system for preventing metal vapor pollution proposed by the present invention has a structure such as figure 1 As shown, it includes a metal vapor anti-pollution system, an optical observation system and a camera cooling sleeve (5), and the metal vapor anti-pollution system includes a fan blade group (1), a motor (3) and an anti-pollution sleeve (2) , the fan blade group (1) and the motor (3) are coaxially installed in the anti-pollution sleeve (2), one end of the anti-pollution sleeve (2) is the front cover (15), and the front cover (15) is provided with There is a peephole (14), and the other end of the anti-pollution sleeve (2) is relatively fixed to one side of the camera cooling sleeve (5) through the motor fixing plate (4), and an observation window is installed on the motor fixing plate (4). One side of the observation window is optical quartz glass (13), and the other side of the observation window is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com