Lithium nickel cobalt manganate positive electrode material and preparation method thereof

A technology of nickel cobalt lithium manganate and cathode material, which is applied in battery electrodes, electrical components, circuits, etc., can solve the problems of unable to meet electric vehicles, unable to reach 3000 times, and the preparation technology needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of nickel cobalt lithium manganese oxide positive electrode material, comprising the steps of:

[0039]Preparation of Ni by hydrothermal method x co y mn 1-x-y (OH) 2 Seed, where x=0.8, y=0.1:

[0040] Nickel acetate, cobalt acetate and manganese acetate were mixed and dissolved in deionized water at a molar ratio of Ni:Co:Mn of 8:1:1, and then a shape guiding agent (specifically sodium dodecylbenzenesulfonate) was added to obtain Homogeneous solution system, the added amount of the shape guiding agent is 8wt% of the amount of nickel acetate;

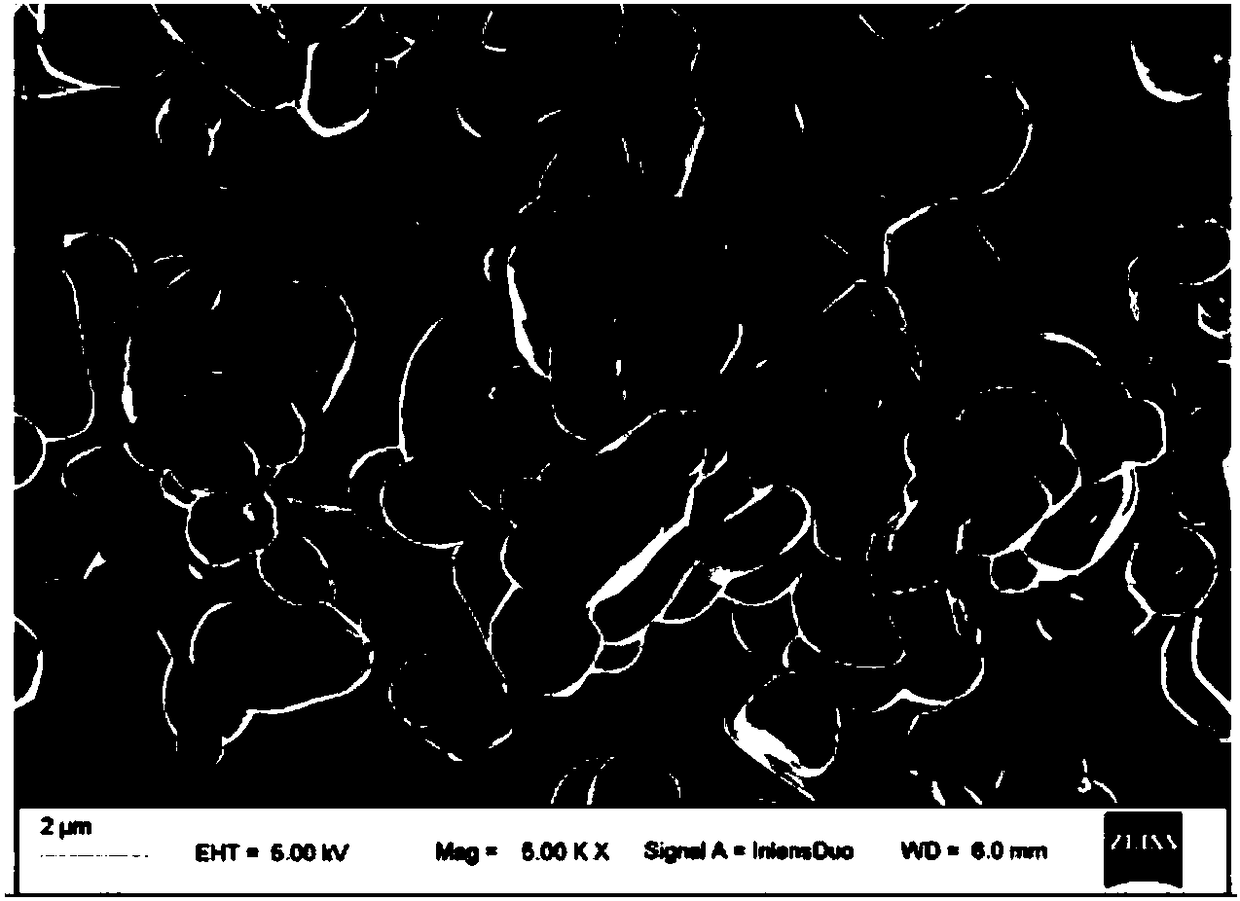

[0041] Put the homogeneous solution system in a reaction kettle, keep the temperature at 150°C and 0.4MPa for 10h, then cool to 25°C, and filter to obtain the Ni x co y mn 1-x-y (OH) 2 A seed crystal, the particle size D50 of the seed crystal is 0.5-1.5 μm.

[0042] Co-precipitate the seeds to obtain Ni x co y mn 1-x-y (OH) 2 Prebody:

[0043] Add the seed crystals into the continuous reactor, a...

Embodiment 2

[0051] A preparation method of nickel cobalt lithium manganese oxide positive electrode material, comprising the steps of:

[0052] Preparation of Ni by hydrothermal method x co y mn 1-x-y (OH) 2 Seed, where x=0.8, y=0.1:

[0053] Nickel acetate, cobalt acetate and manganese acetate were mixed and dissolved in deionized water at a molar ratio of Ni:Co:Mn of 8:1:1, and then a shape guiding agent (specifically sodium hexadecylbenzenesulfonate) was added to obtain Homogeneous solution system, the added amount of the shape guiding agent is 10wt% of the amount of nickel acetate;

[0054] Put the homogeneous solution system in a reaction kettle, keep the temperature at 170°C and 0.35MPa for 8 hours, then cool to 30°C, and filter to obtain the Ni x co y mn 1-x-y (OH) 2 A seed crystal, the particle size D50 of the seed crystal is 0.5-1.5 μm.

[0055] Co-precipitate the seeds to obtain Ni x co y mn 1-x-y (OH) 2 Prebody:

[0056] Add the seed crystals into the continuous r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com