A kind of double-wall pipe used for ship gas pipeline and its installation method

A technology of gas pipeline and installation method, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problem of expanding the annular space of the inner pipe and the outer pipe, increasing the difficulty of ventilation design, increasing the material and Production cost and other issues, to achieve the effect of high impact energy absorption rate, low material and processing cost, material and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

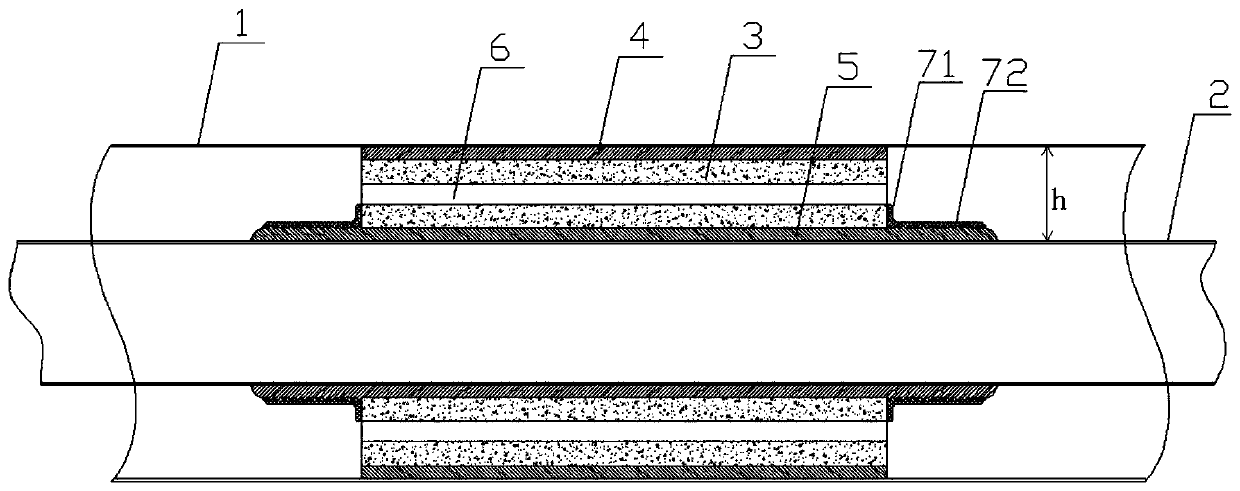

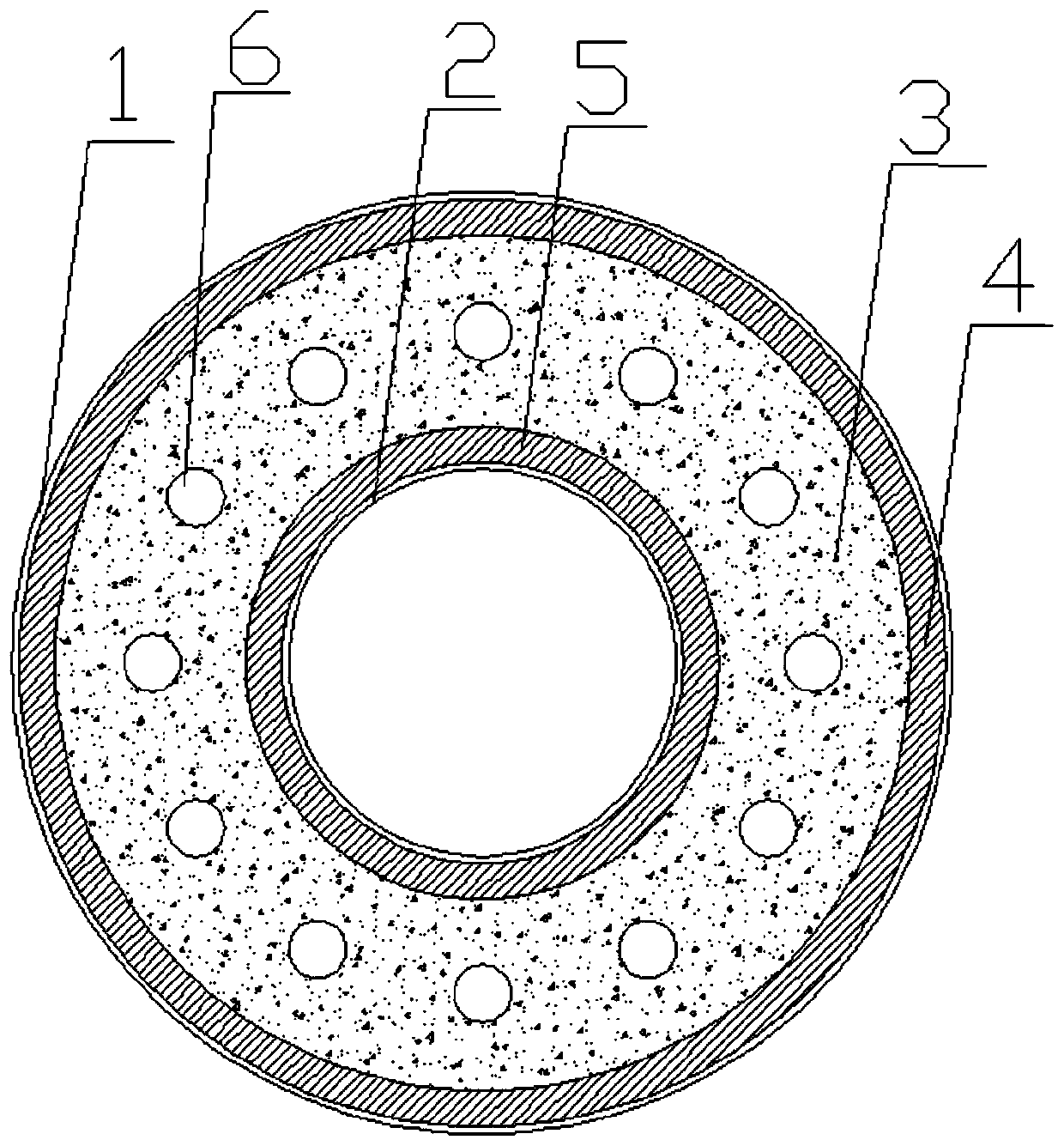

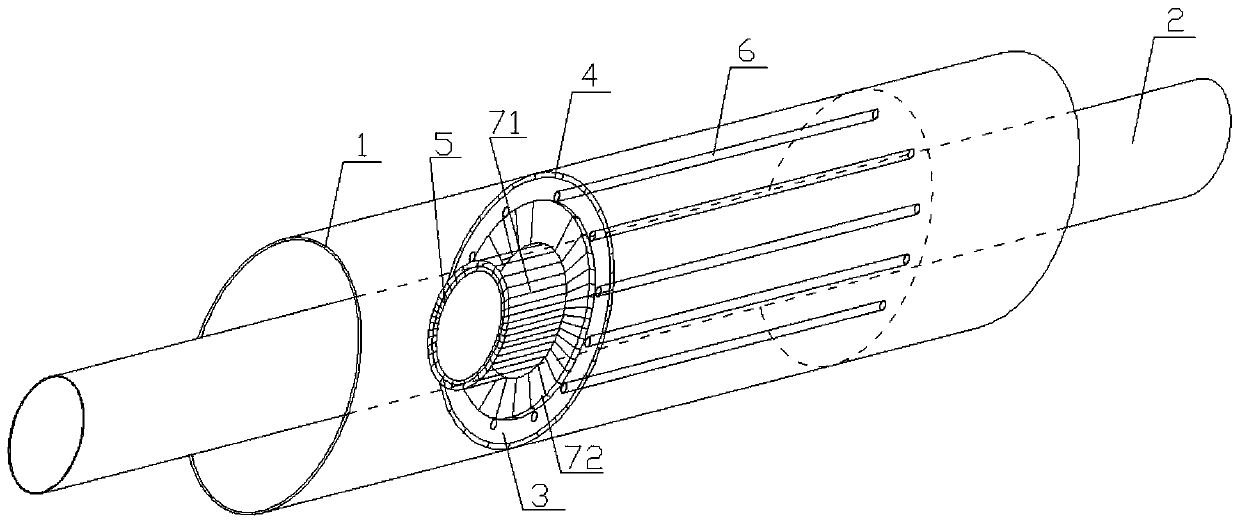

[0046] Such as Figure 1-5As shown, this embodiment is used for the double-walled pipe of the gas pipeline of the ship, and the double-walled pipe includes an outer pipe 1 and an inner pipe 2, and the outer pipe 1 and the inner pipe 2 are arranged coaxially. A bracket 3 is sleeved between the inner tubes 2, and an outer ring interlayer 4 is laid on the inner wall of the outer tube 1, and the outer ring interlayer 4 and the inner wall of the outer tube 1 are bonded and fixed. 2 is provided with an inner ring interlayer 5, there is a gap between the inner wall of the inner ring interlayer 5 and the outer wall of the inner pipe 2, the bracket 3 is sleeved on the inner ring interlayer 5, the inner wall of the bracket 3 is in contact with the inner The outer wall of the ring interlayer 5 is in contact, the outer wall of the bracket 3 is in contact with the inner wall of the outer ring interlayer 4, and several through holes 6 are sandwiched on the bracket along the length direction...

Embodiment 2

[0058] Such as Figure 6 and Figure 7 As shown, this embodiment is used for the double-walled pipe of the gas pipeline of the ship, and the double-walled pipe includes an outer pipe 1 and an inner pipe 2, and the outer pipe 1 and the inner pipe 2 are arranged coaxially. A bracket 3 is sleeved between the inner tubes 2, and an outer ring interlayer 4 is laid on the inner wall of the outer tube 1, and the outer ring interlayer 4 and the inner wall of the outer tube 1 are bonded and fixed. 2 is provided with an inner ring interlayer 5, there is a gap between the inner wall of the inner ring interlayer 5 and the outer wall of the inner pipe 2, the bracket 3 is sleeved on the inner ring interlayer 5, the inner wall of the bracket 3 is in contact with the inner The outer wall of the ring interlayer 5 is in contact, the outer wall of the bracket 3 is in contact with the inner wall of the outer ring interlayer 4, and several through holes 6 are sandwiched on the bracket along the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com