Pull-type stable clutch cover assembly

A clutch cover and stable technology, applied in the field of auto parts, can solve the problems of ease of operation, unsatisfactory use durability, limited working pressing force and transmission torque, and difficulty in reaching the ideal height. , to achieve the effect of light pedal operation, improved ability of pressing force and torque transmission, and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

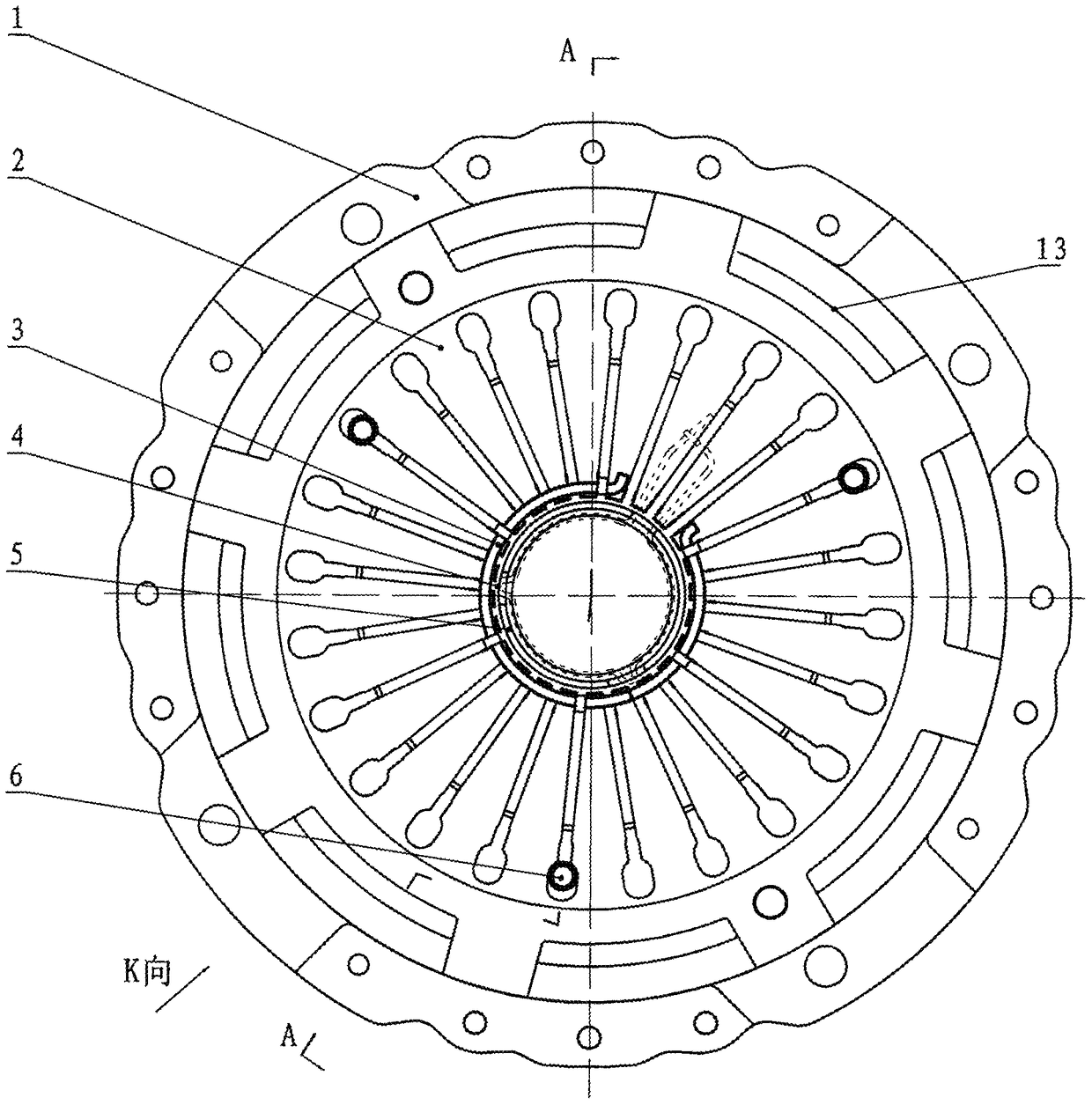

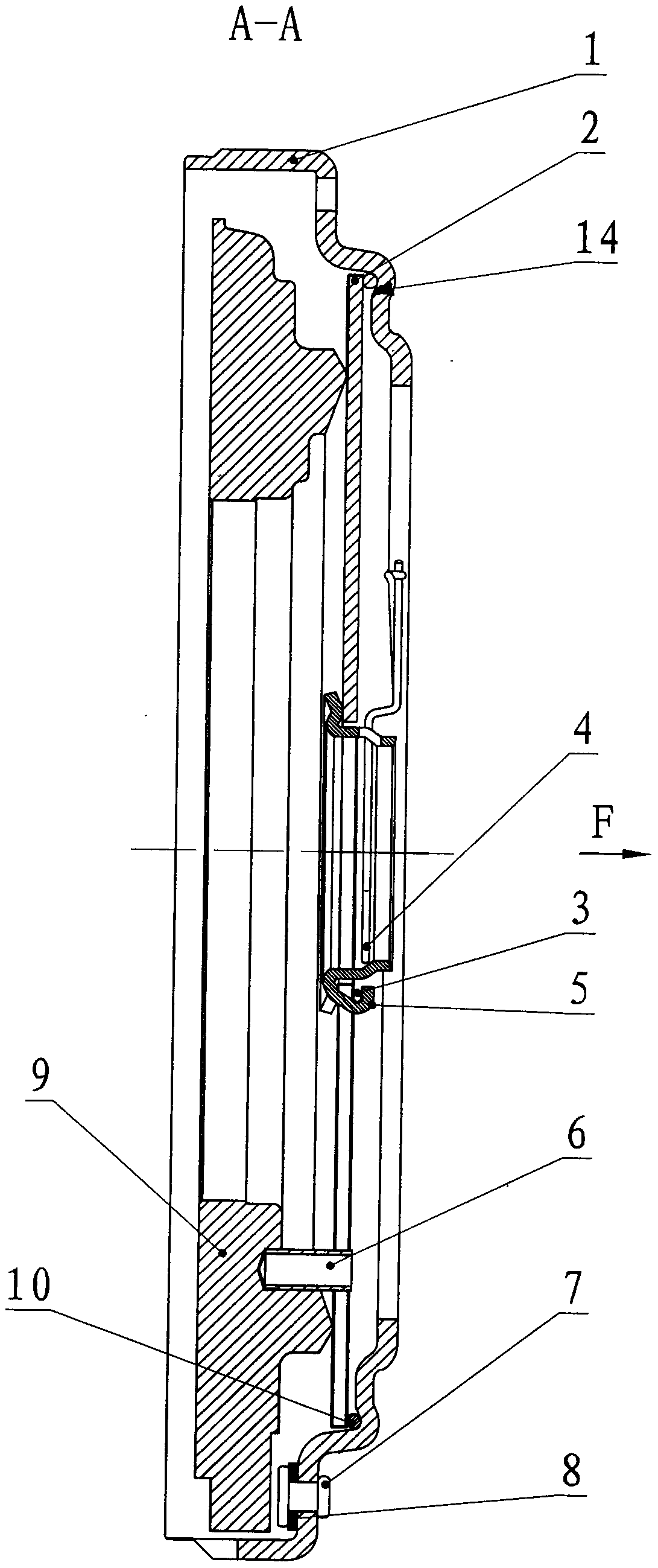

[0011] refer to Figure 1 to Figure 3 It can be seen that the present invention is applied to the pull-type stable clutch cover assembly of the automobile clutch assembly, including a clutch cover 1, a diaphragm spring 2, a pressure plate 9, and a transmission plate 8, and the outer end of the diaphragm spring 2 is mounted There is a backing ring 5, a first snap ring 3 is installed in the backing ring 5 and between the backing ring 5 and the diaphragm spring 2, and a second snap ring 4 is installed outside the backing ring 5; and between the diaphragm springs, elastic cylindrical pins 6 (several, corresponding to the diaphragm springs) are arranged to effectively position the diaphragm spring 2 and prevent its position from moving or rotating in the circumferential direction. Ribs 13 are arranged on the cover 1 to improve the strength of the product.

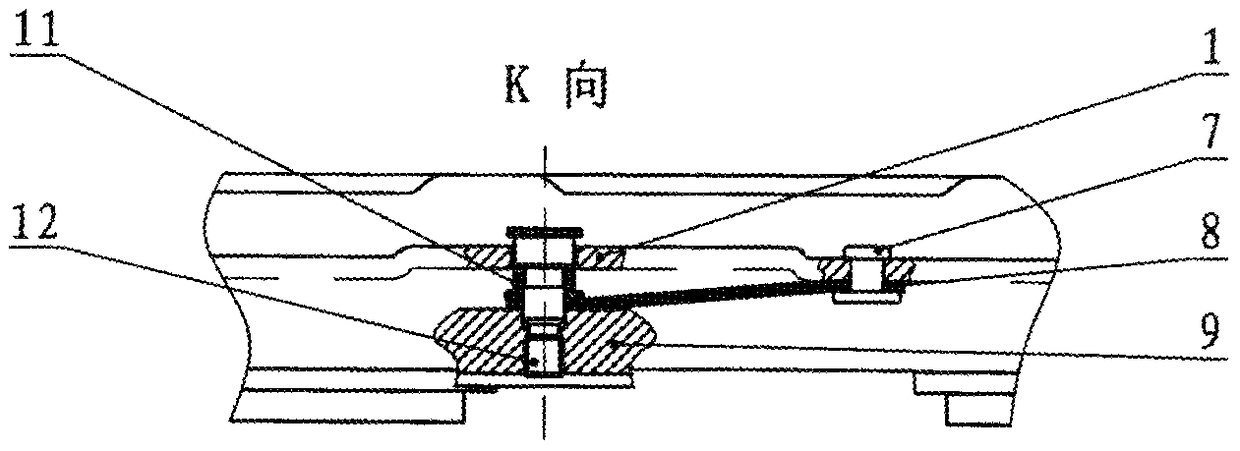

[0012] Such as figure 2 As shown, one end of the transmission plate 8 (through the cover rivet 7) is installed on the clutc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com