Pretensioned arch bridge

A technology for pre-tensioned arch bridges and arch bridges, applied in arch bridges, bridges, bridge forms, etc., can solve the problems of loss of structural stability and bearing capacity, complex structure and maintenance of vault hinges, unsuitable for main arch rings, etc., and achieve large-scale engineering application value. , Increase the vertical and lateral stiffness of the structure and the effect of reasonable stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

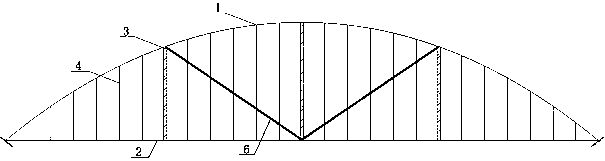

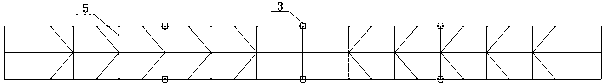

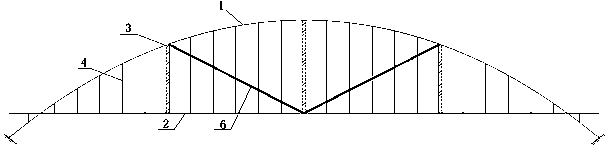

[0068] The span arrangement of the pre-tensioned arch bridge in this embodiment is the same as that of the Yonghe Bridge (total investment 265 million yuan). A pre-tensioned arch bridge mainly consists of arch ribs 1, deck system 2, rigid vertical links 3, flexible suspenders 4, cross braces 5 and pre-tensioned cables 6; 2 and 3 / 4 places respectively set up a pair of rigid vertical links 3, and the rest of the bridge deck system 2 is uniformly arranged with flexible suspenders 4; 2 connection; the rigid vertical link 3 forms a rigid hoop with the bridge deck system 2 and the cross brace 5; the pre-tensioned cable 6 is symmetrically arranged in the middle of the span, and pre-tension is applied, and the upper ends are respectively connected to the arch ribs 1 At 1 / 4 and 3 / 4, the lower end is connected to the bottom of the mid-span rigid vertical link 3; the pre-tensioned cable 6 makes the arch axis elongate through the rigid vertical link 3 to generate tension, thereby offsetti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com