Repair device and repair method for main shaft inner hole of machine tool

A technology of machine tool spindle and inner hole, applied in the direction of metal material coating process, coating, etc., can solve problems such as damage and wear accuracy of inner hole of waste machine tool spindle, avoid re-wear, correct end face runout and radial runout error, the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

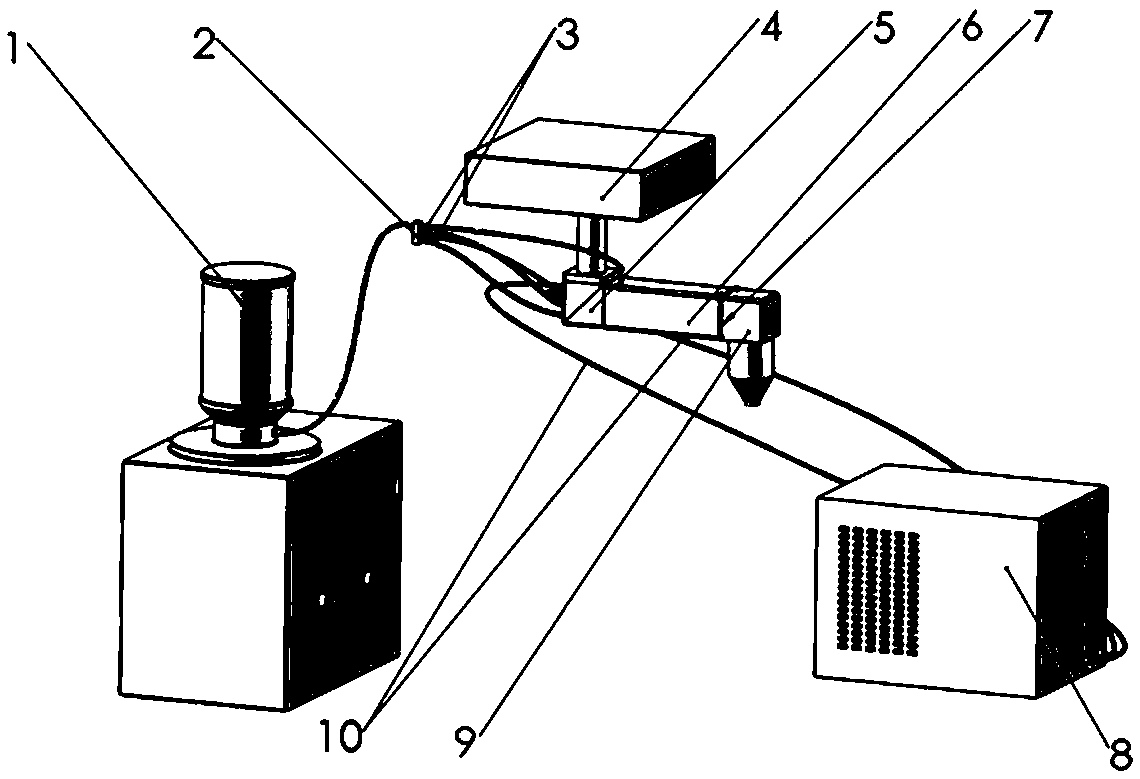

[0031] The technical idea of the present invention is based on the laser cladding technology. The powder feeding device is used to clad the powder on the worn surface of the inner hole of the waste spindle, and at the same time, it is melted by laser to combine with the thin layer metallurgical combination of the surface to be repaired in the inner hole of the main shaft, and solidifies rapidly. Finally, a surface coating with extremely low dilution and metallurgical combination with the inner hole thin layer material is formed, so as to repair the inner hole of the machine tool spindle and achieve the original performance of the matrix.

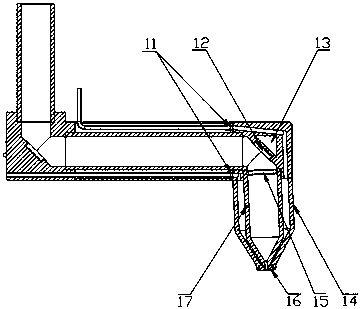

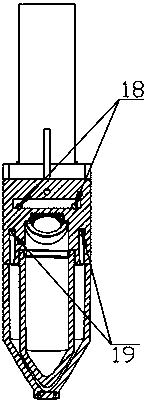

[0032] Below in conjunction with the attached in the embodiment of the present invention figure 1 , figure 2 and image 3 , to describe the technical solutions in the embodiments of the present invention;

[0033] The invention proposes a repair device based on the method of repairing the inner hole of the main shaft of a machine tool, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com