Polypropylene foam material with gradient pore structure and preparation method thereof

A polypropylene foam and gradient cell technology, which is applied in the field of polypropylene foam and its preparation, achieves the effects of low equipment requirements, guaranteed temperature resistance, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

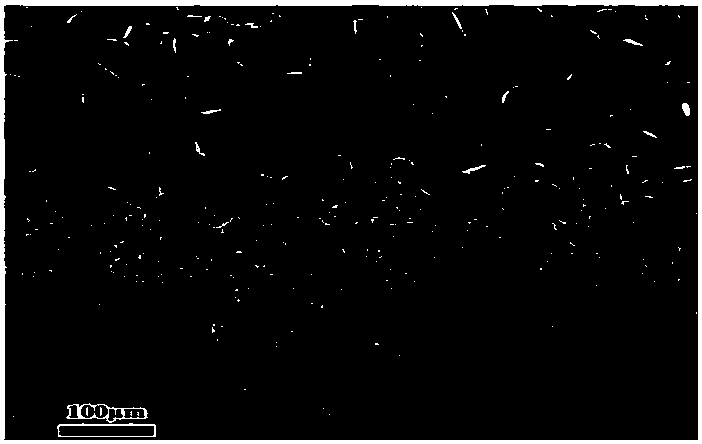

Image

Examples

Embodiment 1

[0036] The preparation method of the polypropylene foam material with gradient cell structure:

[0037] 1) Three kinds of polypropylene resins with different melt strengths and antioxidant B215 are mixed and fed with different nucleating agents respectively, and then multi-layer co-extrusion, wire drawing and pelletizing by an extruder to obtain a three-layer distribution polypropylene resin particles;

[0038] Among them, polypropylenes with different melt strengths are obtained by modifying the same matrix resin (the matrix resin is homopolypropylene, Daqing Petrochemical T30S), and the melt strengths are 2cN, 9cN, and 20cN respectively; the nucleating agents are talcum powder, carbon Nanotubes and graphene are added in amounts of 0.05%, 0.1%, and 0.5% respectively; antioxidant B215 is added in an amount of 0.2wt%.

[0039] 2) Put the polypropylene resin particles with three-layer distribution in the reaction kettle, feed nitrogen gas as the foaming agent, control the press...

Embodiment 2

[0041] The preparation method of the polypropylene foam material with gradient cell structure:

[0042] 1) Three kinds of polypropylene resins with different melt strengths and antioxidant B215 are mixed and fed with different nucleating agents respectively, and then multi-layer co-extrusion, wire drawing and pelletizing by an extruder to obtain a three-layer distribution polypropylene resin particles;

[0043] Among them, polypropylenes with different melt strengths are obtained by modifying the same matrix resin (the matrix resin is homopolypropylene, Daqing Petrochemical T30S), and the melt strengths are 2cN, 8cN, and 26cN respectively; the nucleating agents are talcum powder, carbon Nanotubes and graphene are added in amounts of 0.03%, 0.3%, and 0.9% respectively; antioxidant B215 is added in an amount of 0.2wt%.

[0044] 2) The polypropylene resin particles with three-layer distribution are placed in the reaction kettle, and the blowing agent CO 2 , control the pressure...

Embodiment 3

[0046] The preparation method of the polypropylene foam material with gradient cell structure:

[0047] 1) Three kinds of polypropylene resins with different melt strengths and antioxidant B215 are mixed and fed with different nucleating agents respectively, extruded and granulated by an extruder to obtain polypropylene resin particles with different compositions, The polypropylene resin particles of different compositions are respectively molded to obtain polypropylene sheets of different compositions, which are melted and stacked to obtain a polypropylene resin sheet with a three-layer distribution;

[0048] Among them, polypropylenes with different melt strengths are obtained by modifying the same matrix resin (the matrix resin is homopolypropylene, Daqing Petrochemical T30S), and the melt strengths are 3cN, 5cN, and 15cN respectively; the nucleating agents are calcium carbonate, white The addition amount of carbon black and kaolin is 0.02%, 0.08%, 0.8% respectively; the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com