Segmental lifting method for ship body provided with hatch coaming

A segmented hoisting and hatch enclosure technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as difficult installation methods, inability to weld lifting rings, and poor welding angles, so as to reduce installation difficulty and installation quality , Improve the safety and stability of construction, and reduce the difficulty of welding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

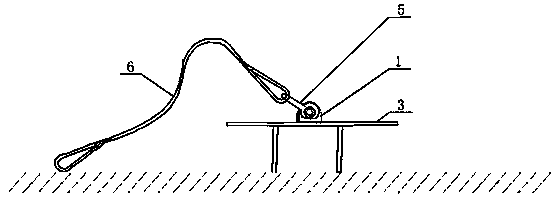

[0024] combine figure 1 This embodiment is described. The segmental hoisting method of the hull with hatch coaming of the present invention can meet the requirement of segmental fast hook throwing of the suspension ring on the lower side of the segment, and can realize the rapid installation of the suspension ring and the wire rope.

[0025] When the hull section is hoisted, the present invention specifically comprises the following steps:

[0026] The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com