Full-automatic medium-speed paper container molding machine

A paper container and forming machine technology, applied in paper/cardboard containers, container manufacturing machinery, containers, etc., can solve the problems of low one-time pass rate, waste of raw material resources, and low production efficiency, so as to improve work efficiency and achieve good results , The effect of heating temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

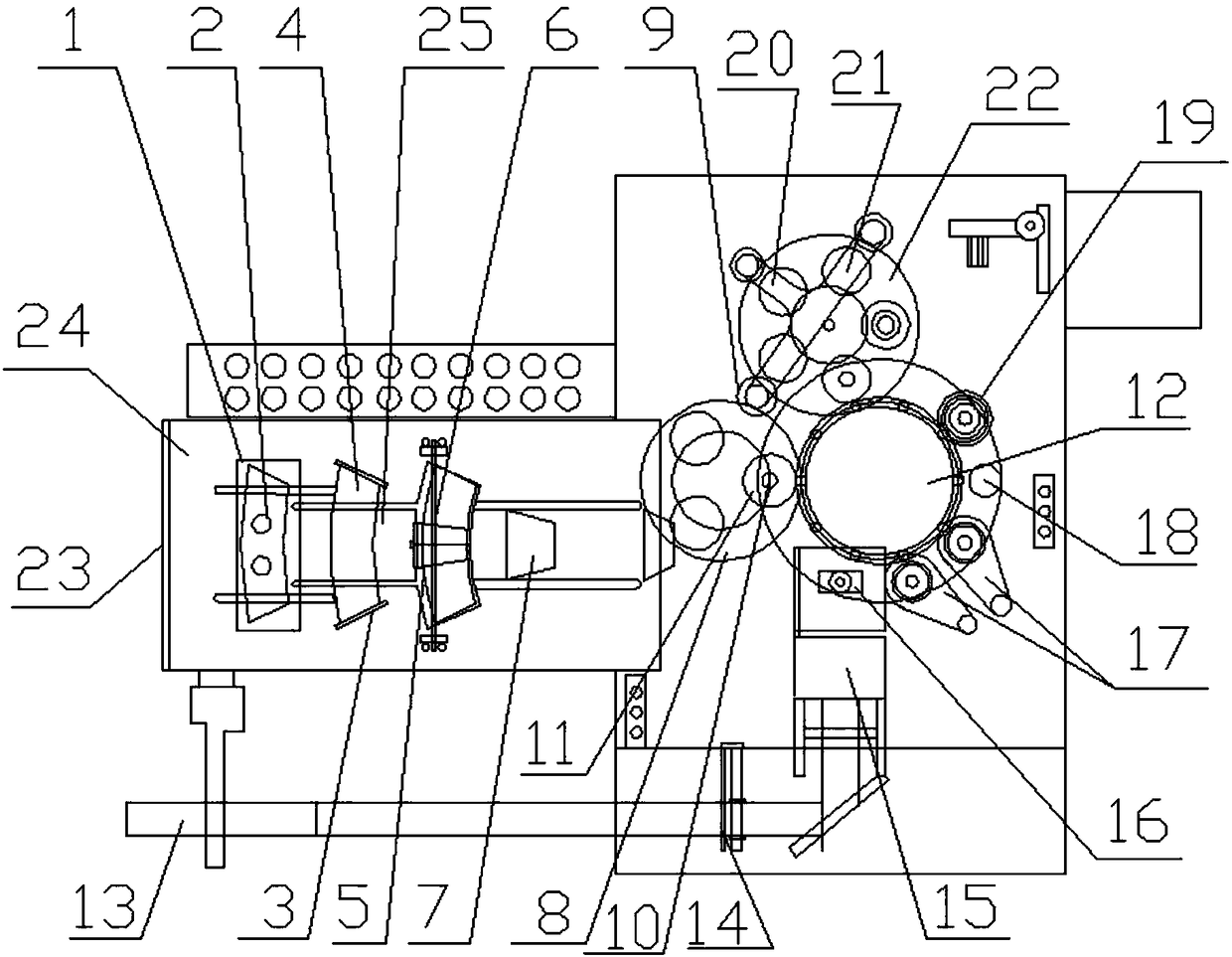

[0034] see figure 1 , a fully automatic medium-speed paper container forming machine, including a raw material rack 23, a panel 24 is arranged on the raw material rack 23, a paper rack 1 is installed on the panel 24, a paper suction mechanism 2 is arranged on the paper rack 1, and a paper sheet The conveying mechanism 4, the upper and lower sides of the paper conveying mechanism 4 are respectively provided with heaters 3, and a paper feeding channel 25 is formed in the middle of the paper conveying mechanism 4, and the end of the paper feeding channel 25 is connected to the cup tube forming mechanism 5, and the top of the cup tube forming mechanism 5 An ultrasonic sealing mechanism 6 is provided, and a cup tube demoulding and pulling mechanism 7 is arranged downstream of the ultrasonic sealing mechanism 6. There is an oiler 9, and the manipulator turntable 8 is provided with a cup tube top feeding connecting rod 10, and the cup tube top feeding connecting rod 10 is connected w...

Embodiment 2

[0043] see figure 1 , a fully automatic medium-speed paper container forming machine, including a raw material rack 23, a panel 24 is arranged on the raw material rack 23, a paper rack 1 is installed on the panel 24, a paper suction mechanism 2 is arranged on the paper rack 1, and a paper sheet The conveying mechanism 4, the upper and lower sides of the paper conveying mechanism 4 are respectively provided with heaters 3, and a paper feeding channel 25 is formed in the middle of the paper conveying mechanism 4, and the end of the paper feeding channel 25 is connected to the cup tube forming mechanism 5, and the top of the cup tube forming mechanism 5 An ultrasonic sealing mechanism 6 is provided, and a cup tube demoulding and pulling mechanism 7 is arranged downstream of the ultrasonic sealing mechanism 6. There is an oiler 9, and the manipulator turntable 8 is provided with a cup tube top feeding connecting rod 10, and the cup tube top feeding connecting rod 10 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com