Chipboard and production method thereof

A technology of particleboard and shavings, which is applied to other household appliances, household components, flat products, etc., can solve the problems of poor glue sizing uniformity, difficult glue mixing, high viscosity of formaldehyde-free glue, etc., to increase uniformity, improve efficiency, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

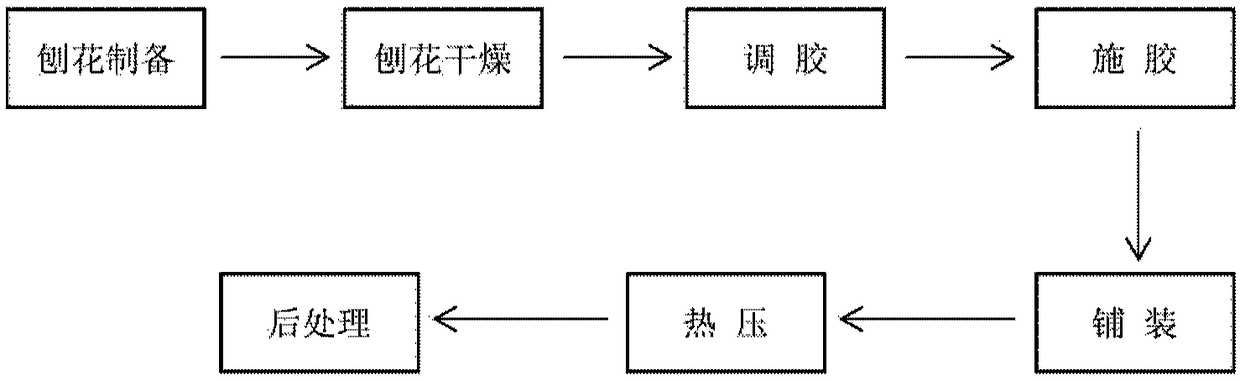

[0040] The flow chart of the particleboard production method according to the exemplary embodiment of the present disclosure is as follows: figure 2 shown. according to figure 2 , the preparation method of particle board comprises the following steps:

[0041]Preparation of shavings: prepare straw and wood into shavings, and divide them into surface shavings and core shavings according to the types of shavings, wherein the surface shavings are straw shavings, and the core shavings include wood shavings, and can further include Straw shavings. Surface shavings are fine straw shavings screened by 4.0-5.5mm sieves, which can increase compactness, improve surface strength and aesthetics when used on the surface; at the same time, wood shavings applied to the core layer can enhance the mechanical properties of the core layer.

[0042] Drying of shavings: Dry the shavings of the surface and the core layer through a dryer, so that the moisture content of the shavings of the surf...

Embodiment 1

[0056] Cut and crush crop straw and wood chips to make shavings, which are divided into surface shavings and core shavings according to the shape and type of shavings. Among them, the surface shavings are 100% straw shavings; the core shavings are 30% wood shavings, 30% straw shavings, 30% % Cotton stalk shavings and 10% Rapeseed stalk shavings. The surface layer and the core layer of shavings were dried to a moisture content of 9%-12% and 5%-7%, respectively, and then 10% by weight of water-dispersed polyisocyanate was applied for the experiment. Among them, the water-dispersed polyisocyanate is diluted with water to reduce the viscosity, and the sizing is carried out at room temperature. The surface and core layer particles after sizing are paved, and the particle board is obtained through hot pressing and further post-treatment. Among them, the particleboard density is controlled at 720kg / m 3 about.

[0057] 1. Steps

[0058] (1) Preparation of shavings

[0059] Use a ...

Embodiment 2

[0089] Carry out embodiment 2 in the same manner as Example 1, except that the water-dispersible polyisocyanate of 50% solid content is replaced by 7.5% solid content of 50% water-dispersible polyisocyanate, and the density is controlled at 750kg / m 3 about.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com