Grinding and removing device for spigot of adjustable galvanized plate end cover

A galvanized sheet and adjustable technology, which is applied in the direction of grinding machines, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problems of low grinding efficiency and reduced roundness of end caps, and achieve fast grinding speed and ensure single machine Noise, effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

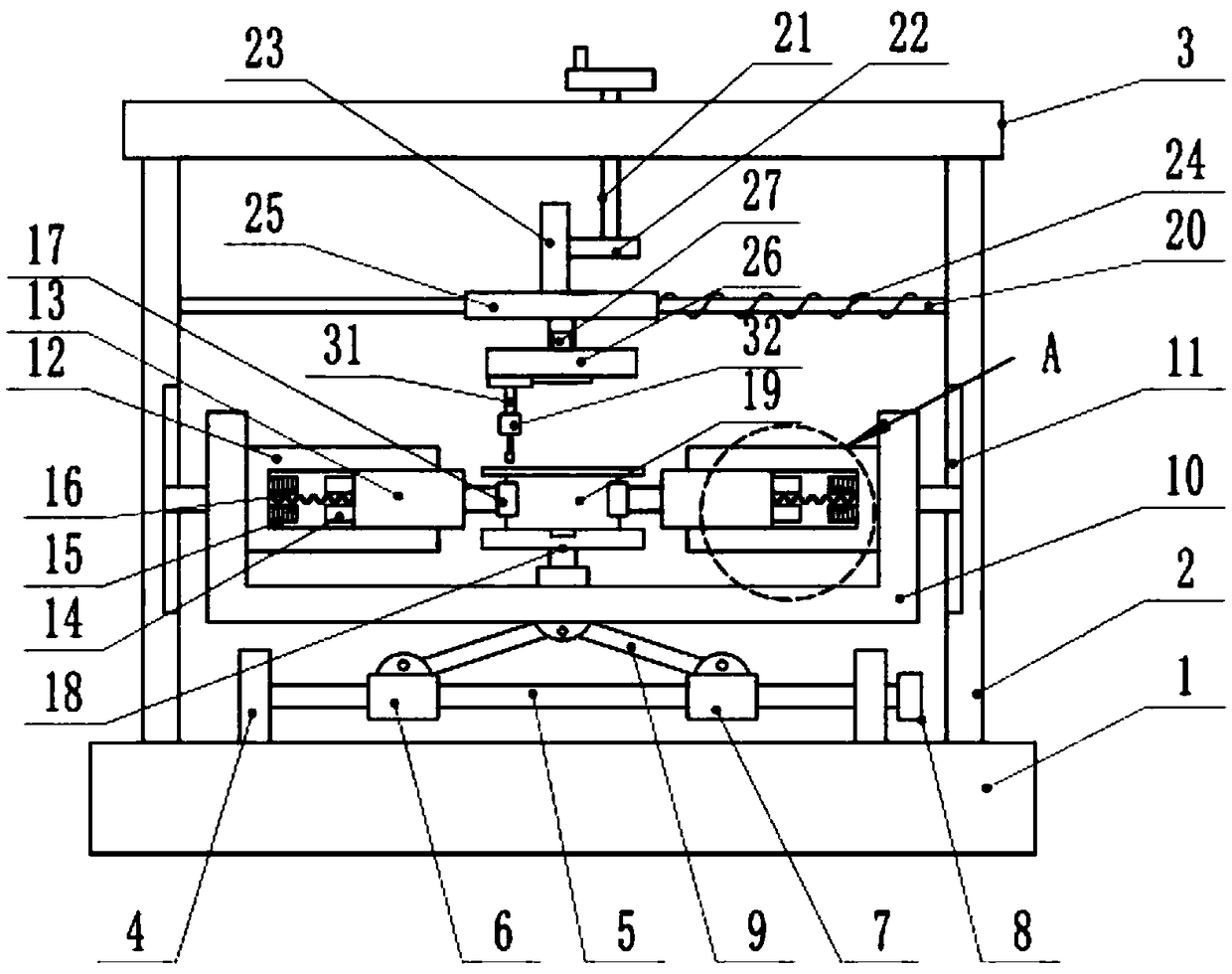

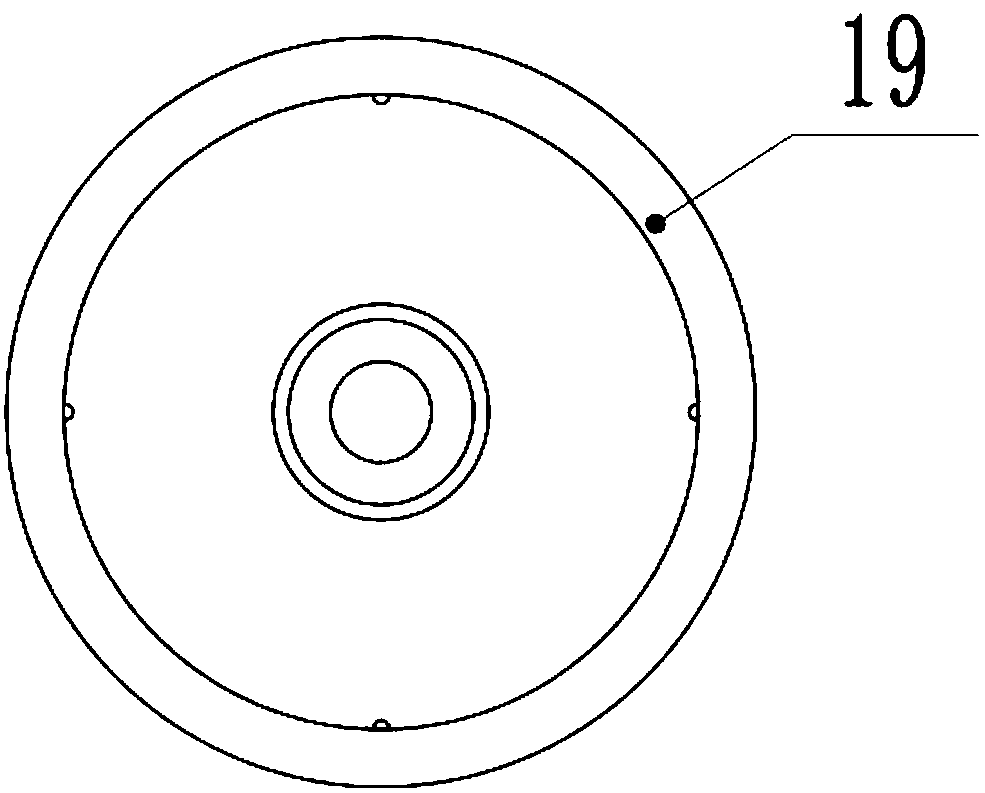

[0025] See Figure 1-4 , An adjustable galvanized sheet end cap grinding and removing device, comprising a base 1, a clamping device 12, an internal tooth disc 26, a rotating motor 27, and a grinding device 32. The upper surface of the base 1 is symmetrically arranged on the left and right sides There is a support plate 2, the support plate 2 and the base 1 are fixedly connected by screws, the inner side of the support plate 2 is provided with a slide rail 11, the upper end of the support plate 2 is fixedly connected with a top cover 3, and the upper surface of the base 1 is also provided with symmetrical connections A screw rod 5 is installed between the connecting plates 4 on the left and right sides through a bearing rotation. The right end of the screw rod 5 passes through the connecting plate 4 on the right side and is welded with an adjusting kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com