Preparation method of multi-functional group antibacterial biogas residue adsorbent for adsorbing heavy metals and anions

A technology for adsorbing heavy metals and anions, which is applied in chemical instruments and methods, alkali metal compounds, adsorbed water/sewage treatment, etc. It can solve the problem of single removal of heavy metals or anions by adsorbents, and achieve increased reactive sites and good antibacterial properties. , the effect of improving mechanical strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

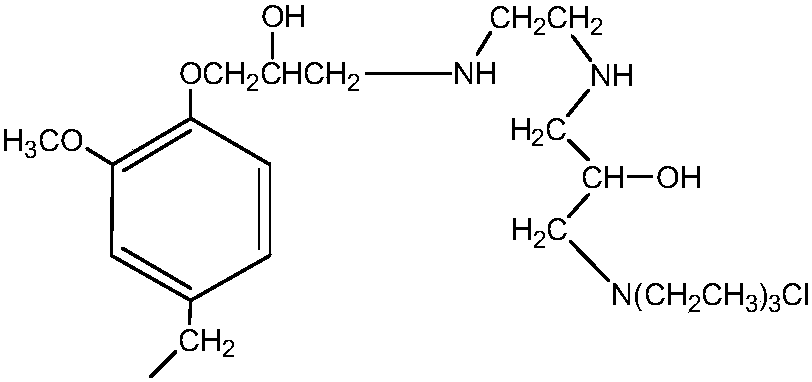

Image

Examples

Embodiment 1

[0037] A preparation method of an antibacterial biogas residue adsorbent with multifunctional functional groups for adsorbing heavy metals and anions, comprising the following steps:

[0038] Stir and react corn stalk residue with epichlorohydrin and N,N-dimethylformamide (DMF), add crosslinking agent ethylenediamine, and then add triethylamine solution, the ratio of ingredients between them is corn Straw biogas residue: epichlorohydrin: ethylenediamine: triethylamine solution = 2g: 5mL: 1mL: 5mL, and a corn biogas residue-based multifunctional antibacterial biogas adsorbent was prepared. The product is represented by No.1. The specific preparation method is as follows:

[0039] (1) Take 2g of corn stalk residue with a particle size of 300-500μm in a 250mL three-necked flask, add 5mL of epichlorohydrin, stir and add 5mL of N,N-dimethylformamide as the reaction medium, and put it at 80°C Under stirring reaction 30min;

[0040](2) Take 1 mL of the cross-linking agent ethylene...

Embodiment 2

[0044] A preparation method of corn biogas residue-based multifunctional antibacterial biogas residue adsorbent, comprising the following steps:

[0045] Stir and react corn stalk residue with N,N-dimethylformamide (DMF) and epichlorohydrin, add crosslinking agent diethylenetriamine, and then add triethylamine solution. The ratio of ingredients between them is Biogas residue: epichlorohydrin: diethylenetriamine: triethylamine solution = 2g: 5mL: 2mL: 5mL, and a corn biogas residue-based multifunctional antibacterial biogas adsorbent was prepared. The product is represented by No.2. The specific preparation method is as follows:

[0046] (1) Take 2g of corn stalk residue with a particle size of 300-500μm in a 250mL three-necked flask, add 5mL of epichlorohydrin, stir and add 5mL of N,N-dimethylformamide as the reaction medium, and put it at 90°C Under stirring reaction 30min;

[0047] (2) Add 2 mL of cross-linking agent diethylenetriamine into the above-mentioned 250 mL thre...

Embodiment 3

[0051] A preparation method of sorghum biogas residue-based multifunctional antibacterial biogas residue adsorbent, comprising the following steps:

[0052] Stir the sorghum straw biogas residue with N,N-dimethylformamide and epichlorohydrin, add the crosslinking agent ethylenediamine, and then add the triethylamine solution. The ratio of ingredients between them is biogas residue: ring Oxychloropropane: ethylenediamine: triethylamine solution = 2g: 10mL: 4mL: 10mL, so that sorghum biogas residue-based multifunctional antibacterial biogas residue adsorbent was prepared. The product is represented by No.3.

[0053] The specific preparation method is as in Example 1, except that the biogas residue is selected from sorghum straw, 10 mL of epichlorohydrin, 10 mL of N,N-dimethylformamide, 4 mL of ethylenediamine, and 4 mL of triethylene The volume of amine was 10 mL, and the reaction temperature was 75 °C. The obtained sorghum biogas residue-based high-efficiency anion adsorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| aqueous solution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com