Shrimp shelling device

A shrimp and conveying device technology, applied in shrimp/lobster processing and other directions, can solve the problems of low production efficiency, high labor intensity for manual shelling, and bacterial contamination of products, and achieves reasonable design, convenient operation, and fast separation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

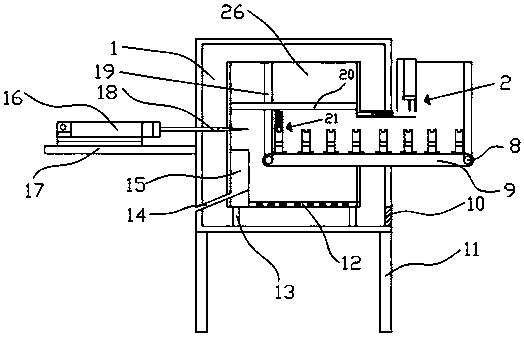

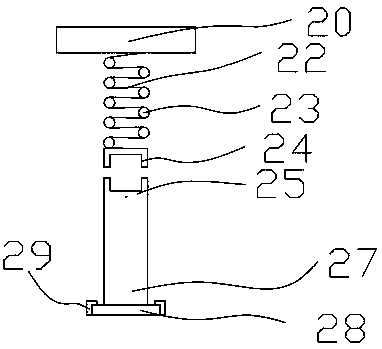

[0023] Such as Figure 1-6 As shown, a shrimp shelling device includes a housing 1, a bracket 11 is provided below the housing 1, a separation box 26 is provided inside the housing 1, and a collection box 15 is provided on the left side of the separation box 26. The collection box 15 is provided with a discharge pipe 14 inside, a top bar 13 is provided below the separation box 26, a head removal device 2 is provided above the outside of the right side of the housing 1, and a transmission device is provided inside the housing 1, and a clamping device is movably connected to the transmission device. The device 21 is provided with a cylinder 16 outside the left side of the casing 1 . The separation process is carried out in the separation box, the separation speed is fast, the separated shrimp will fall into the collection box, and the collected shrimp will slide out from the discharge pipe, and the top strip can separate the separation box from the shell, so that the garbage can...

Embodiment 2

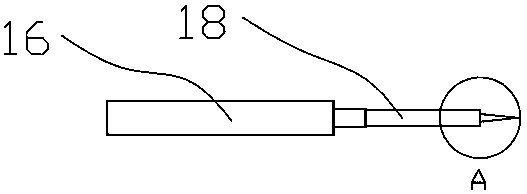

[0032] Such as Figure 1-6 As shown, a shrimp shelling device, the working principle is: put the whole shrimp into the shrimp inlet 3 of the head removing device 2, when the shrimp falls to the bottom, the pneumatic part 7 pushes the push rod 35 out, and the push rod 35 pushes the shrimp Enter below the blade 5, the first rolling 4 drives the blade to move downwards, the head of the shrimp is removed, and then the shrimp is taken out from the shrimp outlet after removal. Put them on the lower clamping block 25 one by one, the conveyor belt 9 will transfer the shrimp to the range where the shrimp meat is poked, and the cylinder 16 will quickly push the positioning pin 18 out and insert it into the meat of the shrimp. At the same time, the steel needles 34 on both sides of the positioning pin 18 The meat of the shrimp will be hooked, and after hooking, the cylinder 16 will be quickly recovered, and the positioning pin 18 will also retract out of the separation box 26, and the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com