Vibration screening type sunflower seed threshing and screening device

A vibration screening and screening device technology, applied in threshing equipment, applications, agricultural machinery and implements, etc., can solve the problems of low work efficiency, long slack time for farmers, and large damage to sunflower seeds, so as to improve work efficiency and improve threshing effect. , the effect of speeding up the screening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

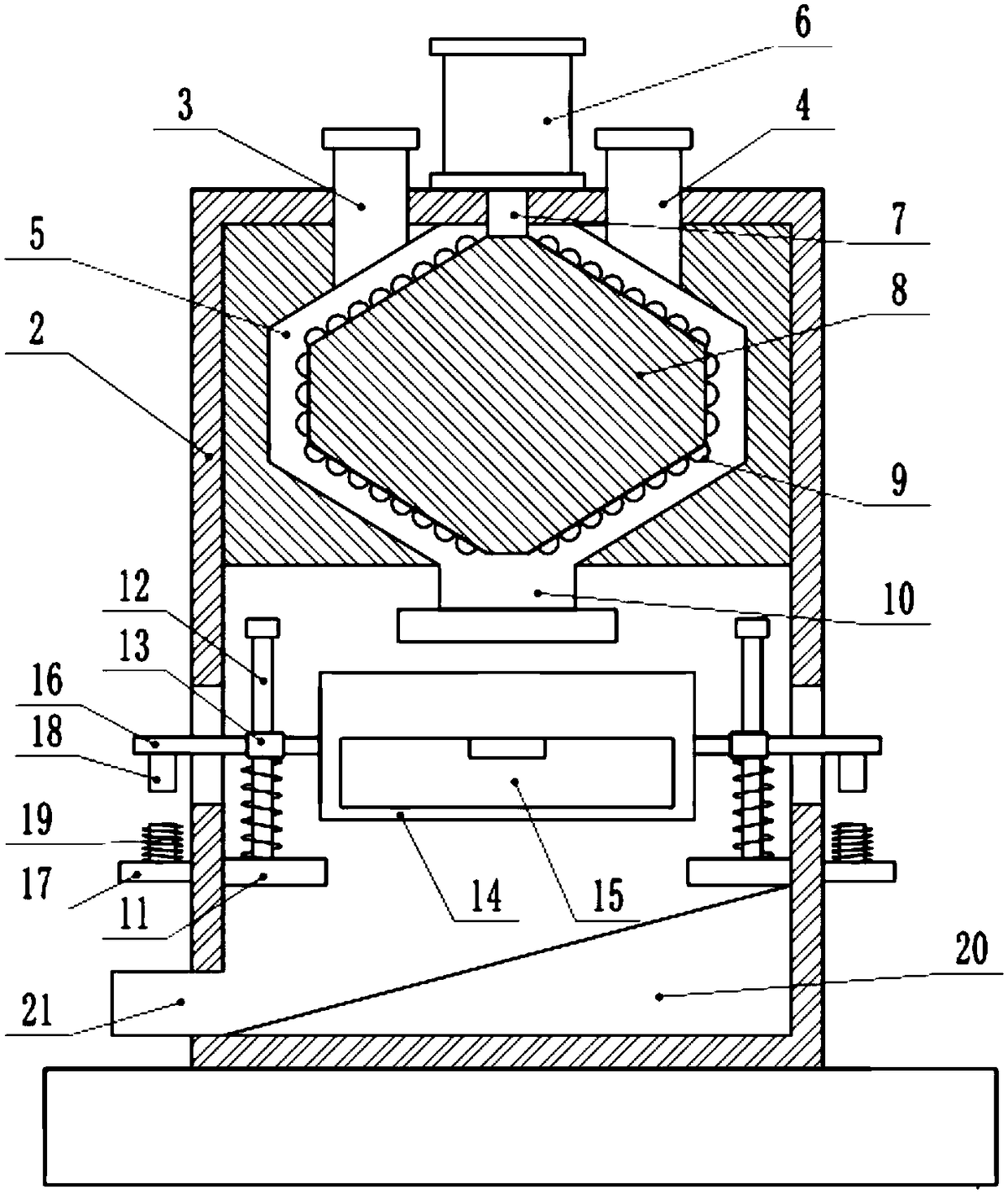

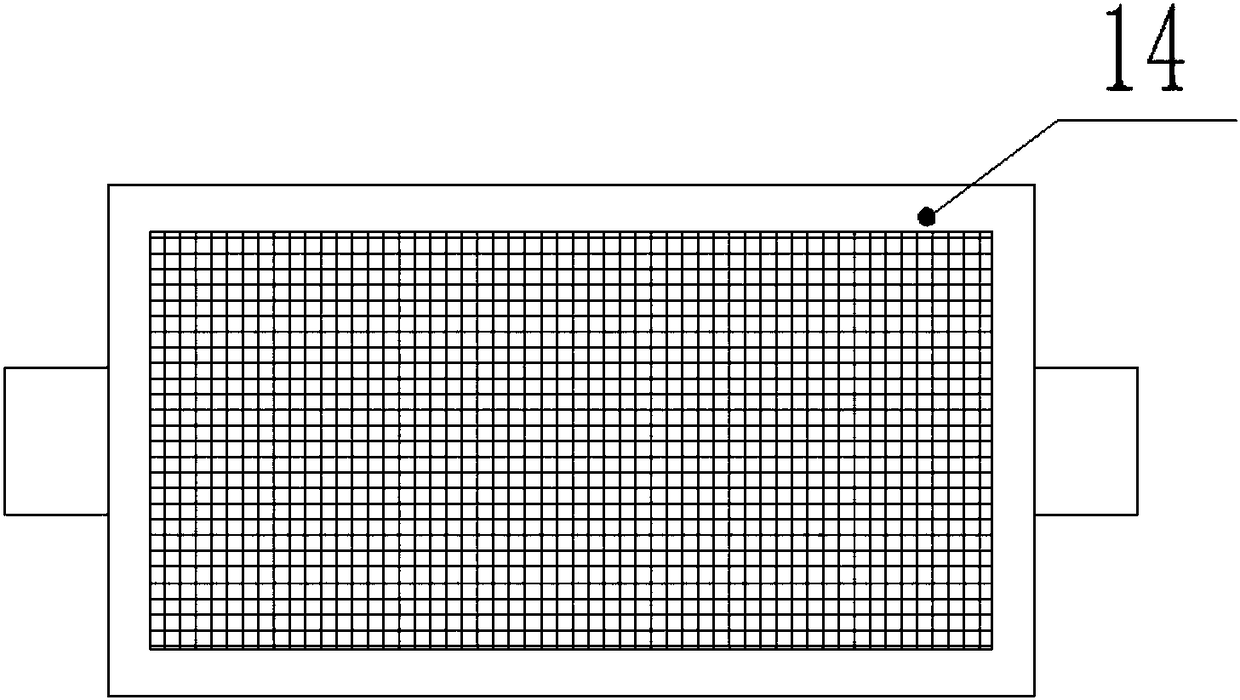

[0021] see Figure 1-2 , a vibrating screening type sunflower seed threshing and screening device, comprising a base 1, a threshing box 2, a rotating motor 6, a threshing head 8 and a screening box 14, the base 1 is provided with a threshing box 2, the threshing box 2 and the base 1 The threshing box 2 is fixedly connected by bolts. The upper side of the threshing box 2 is symmetrically provided with a first feeding port 3 and a second feeding port 4. The inside of the threshing box 2 is provided with a threshing chamber 5. A rotary motor 6 is fixedly installed at the center of the side, the output shaft of the rotary motor 6 is vertically downward and the output shaft of the rotary motor 6 penetrates into the threshing chamber 5, and the output shaft of the rotary motor 6 passes through the shell of the threshing box 2 The bearing is connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com